Pneumatic tube needle installation machine

A technology for air pressure pipes and installation machines, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of increasing enterprises' dependence on unreliable factors, wasting parts and man-hours, and complicated tool design, so as to maintain production processes and maintain production stability. performance, reduce work pressure, and save materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The utility model will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the utility model and are not intended to limit the scope of the utility model.

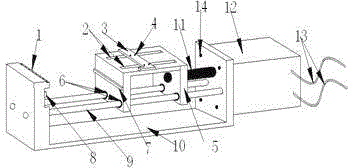

[0011] Such as figure 1 The present invention shown includes rack 1, fixing groove 2, sliding ruler 3, fixing screw 4, sliding bracket 5, bearing 6, lower file 7, upper file 8, guide rail 9, workbench 10, transmission rod 11, pneumatic device 12, air guide tube 13, fixing screw 14. The workbench 10 is composed of a base and front and rear baffles, the rack 1 is horizontally located on the upper edge of the front baffle of the workbench 10, and the upper file 8 is horizontally located in the concave groove above the front baffle of the workbench 10. Described sliding bracket 5 is made up of platform and front and rear vertical surface, and the platform of sliding bracket 5 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com