Continuous die for manufacturing automobile seat sliding way holder and method for manufacturing automobile seat sliding way holder

A technology for car seats and cages, applied in the field of continuous molds, can solve the problems of inability to manufacture slide cages, low stamping efficiency, poor stability, etc., and achieves reasonable overall structural design and arrangement, accurate transportation, and uniform transportation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0049] see figure 1 , the cage 1 manufactured by the present invention is a finished product symmetrically distributed according to the center line 01, which includes a steel ball groove 11, a center groove 12, a trimming edge 13, forming teeth 14, opposite side bending 15, The coil 16, the groove bending 17 and the cutting edge 19 also include two steel balls 18 movably installed in the steel ball groove 11, and the two steel balls 18 are respectively distributed on both sides of the center line 01.

[0050] The cage 1 is made of metal material.

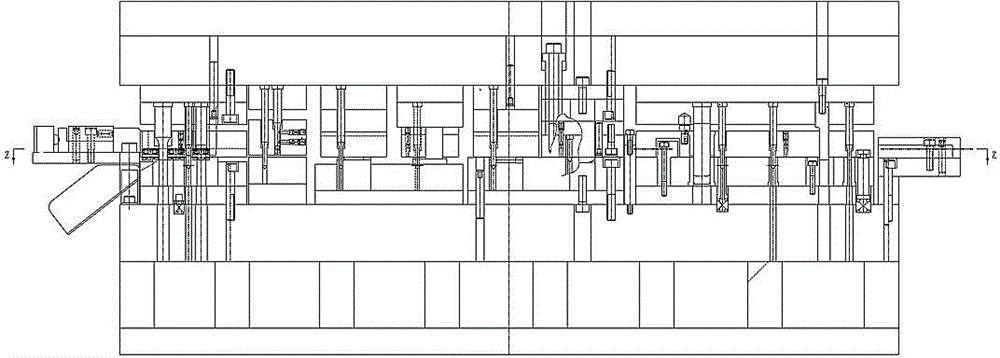

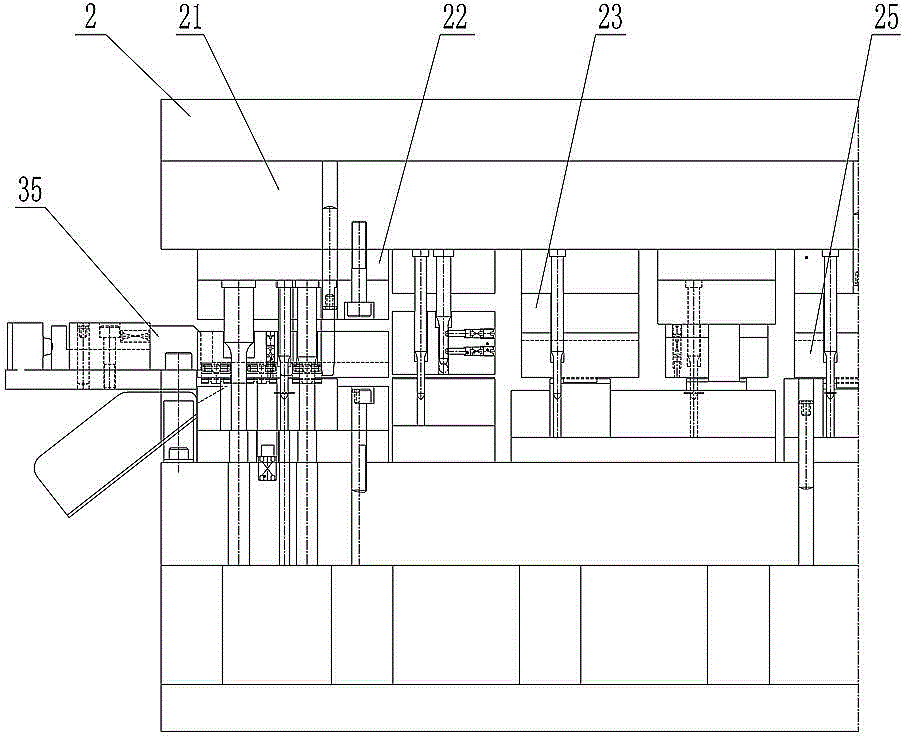

[0051] see Figure 1 to Figure 18 , the present invention comprises upper formwork 21 in patrix 2, upper mold backing plate 22, upper mold fixing plate 23 and stripping plate 25, and lower formwork 31 in lower mold 3, lower mold fixing plate 32, lower mold backing plate 33, the material guide device 34 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com