Precise extruding and forming method for long barrel-shaped component with base

A technology of extrusion forming and long barrel, which is applied in the field of precision extrusion forming of long cylindrical parts with a bottom, which can solve the problems of large machining allowance, low material utilization rate, and low punch life, so as to improve the uniformity of wall thickness , Reduce equipment investment and prolong the life of the punch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

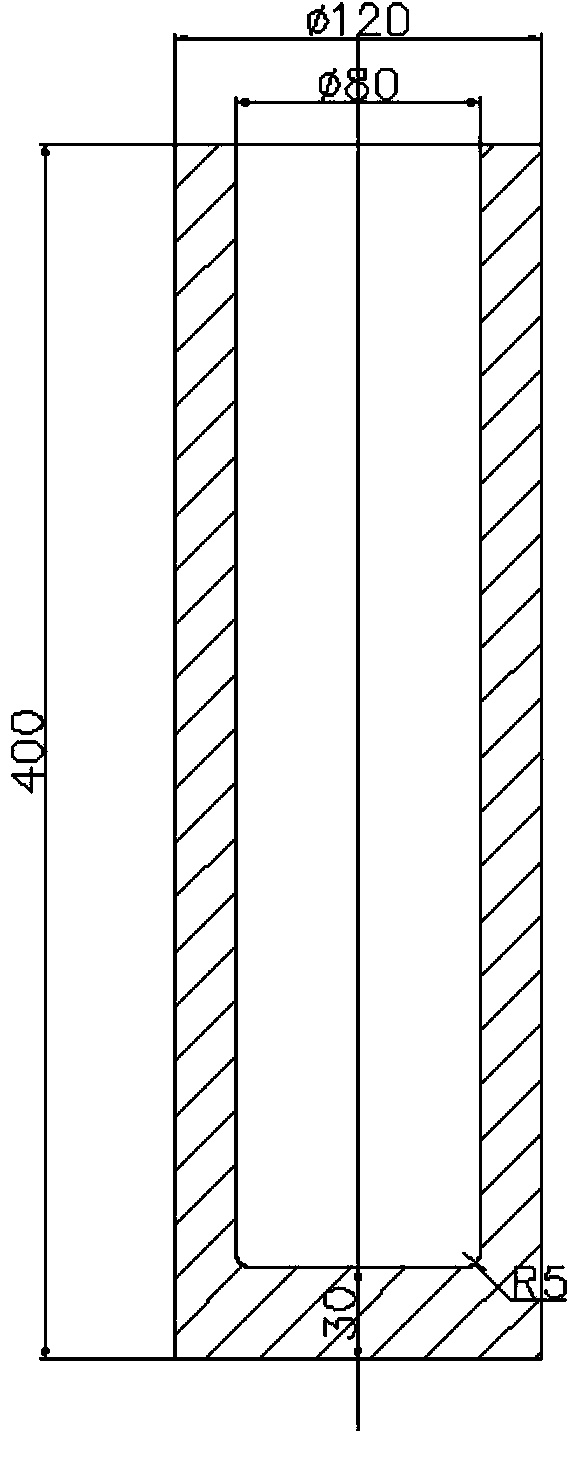

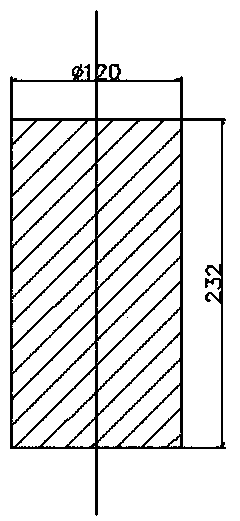

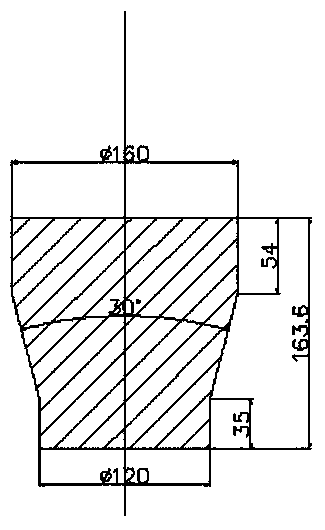

[0040] Such as figure 1 As shown, it is a typical long cylindrical part with a bottom, the material is 40Cr, the precision requires that the coaxiality of the inner and outer walls is ≤1mm, and the rest of the dimensions are required to reach the precision level of the steel die forging standard, and the long cylindrical part with a bottom is precisely and quickly formed. The process diagram is as follows Figure 2a to Figure 2e As shown, the equipment used is a frame-type fast hydraulic press, and the specific implementation steps are as follows:

[0041] 1) Blank heating

[0042] The sawed round steel or square steel enters the intermediate frequency induction heating furnace through the conveying device for heating, and the heating temperature reaches the initial forging temperature of the material at 1150-1180°C. After heating, the temperature of the workpiece should be uniform to meet the heating requirements.

[0043] 2) Descaling

[0044] The heated workpiece is cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com