Reduction and passivation system for ammonia synthesis catalyst, and method thereof

A technology for catalyst and ammonia synthesis, which is applied in chemical instruments and methods, catalyst protection, physical/chemical process catalysts, etc. It can solve the problems of complex treatment process and low gas recycling rate, and achieve the effect of simple process and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

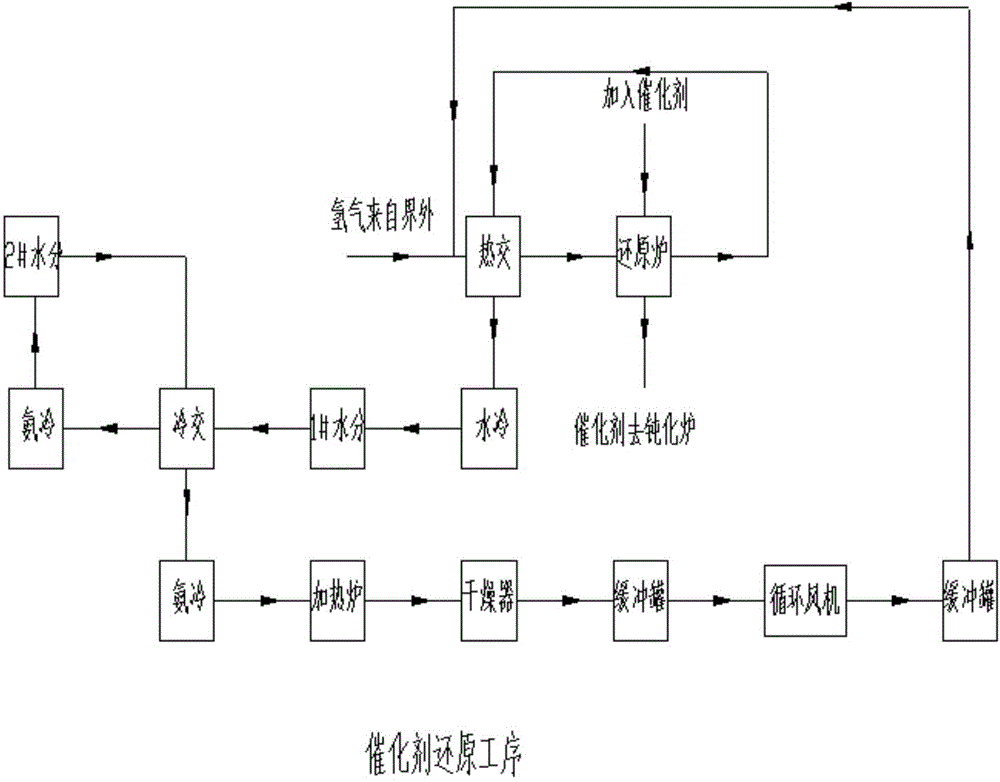

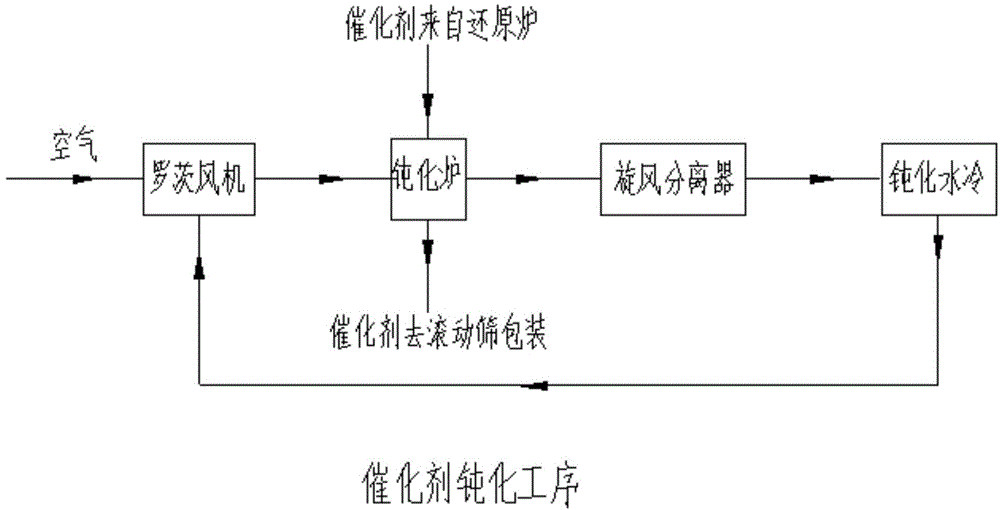

[0024] A high-efficiency catalyst device includes two processes of catalyst reduction and passivation. The main equipment included in the reduction process is reduction furnace, heat exchange, cold exchange, water cooling, ammonia cooling, molecular sieve, dryer, regeneration heating furnace, and circulating fan; the main equipment included in the passivation process is passivation furnace, Roots blower, cyclone Separator, passivated water cooling.

[0025] The process flow is to load the catalyst into the reduction furnace, and the hydrogen gas with a maximum temperature of 500°C passes through the catalyst layer to be reduced in the furnace, and passes through a series of cooling, moisture, drying and heating cycles such as heat exchangers. After the catalyst is reduced, it is put into the passivation furnace, and the passivation is carried out by air heated to 40°C. The temperature in the passivation furnace is controlled at about 60°C. The fan circulates. The passivated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com