A screen-type hydrothermal kettle capable of solid-liquid separation

A solid-liquid separation, hydrothermal kettle technology, applied in filtration separation, separation methods, fixed filter element filters, etc., can solve the problems of complexity, lack of high temperature solubility data, difficult sampling of saturated solutions, etc., to avoid structural transformation and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

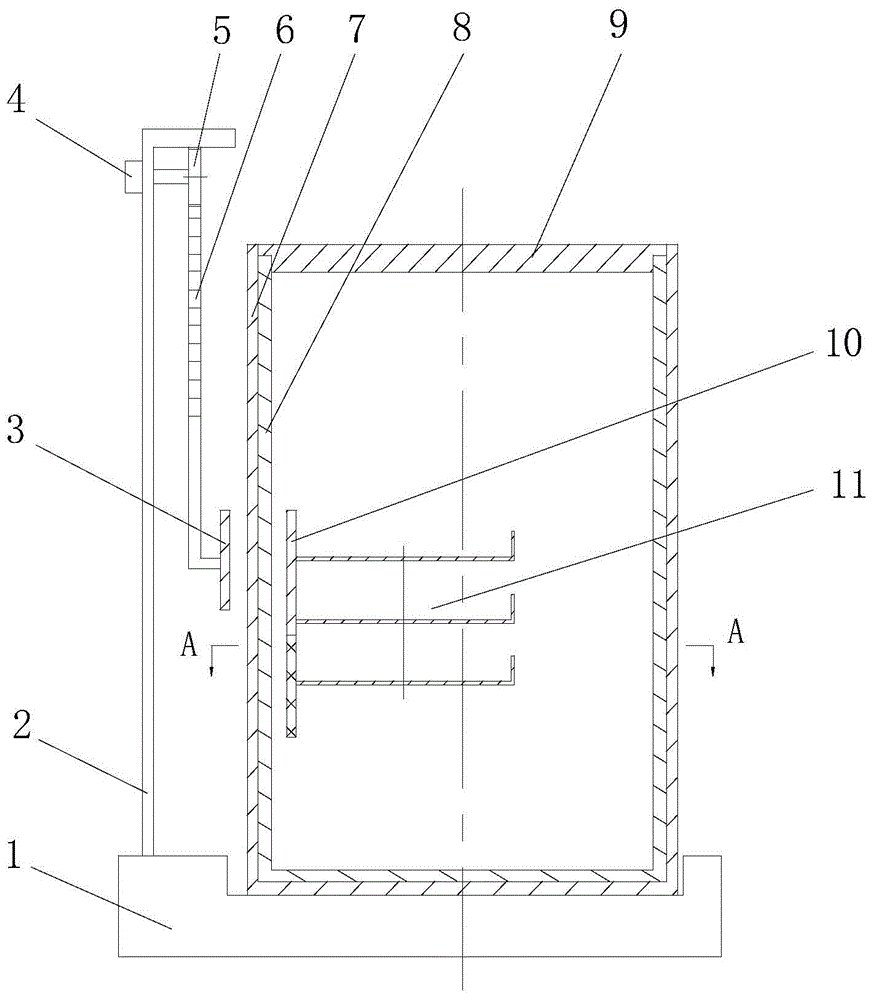

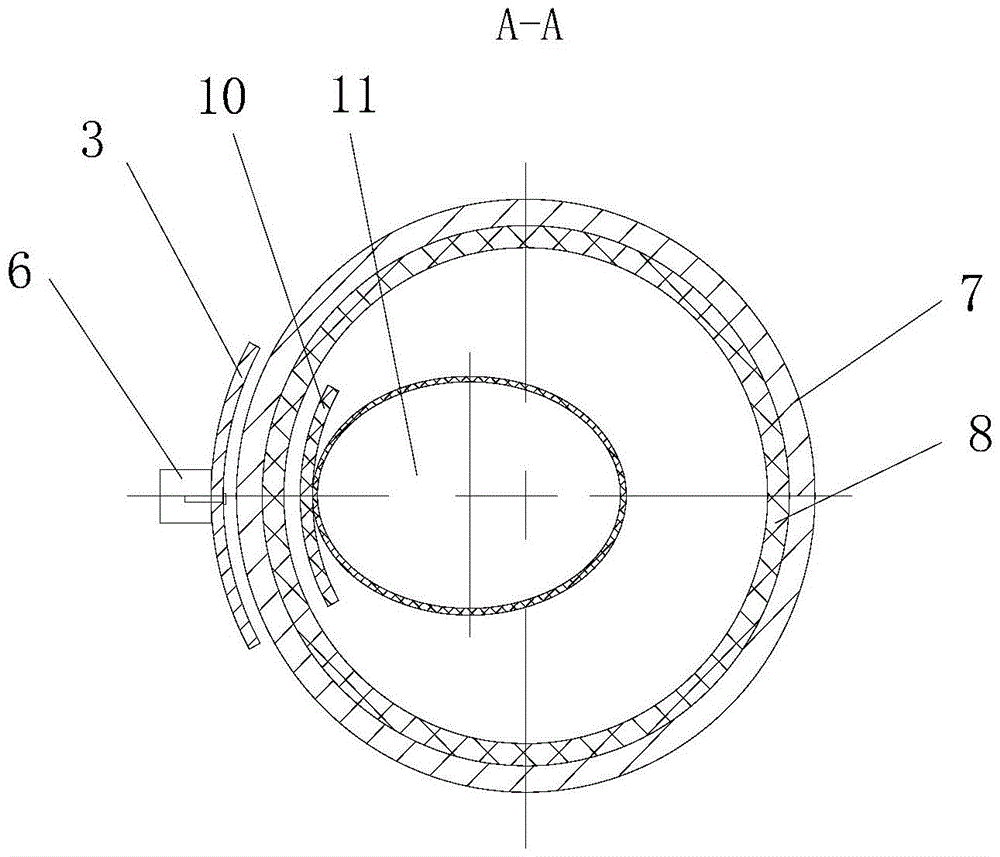

[0027] Depend on figure 1 with figure 2 It can be seen that the solid-liquid separable screen-type hydrothermal kettle of this embodiment is composed of a base 1, a bracket 2, an outer magnetic fixing plate 3, an adjustment knob 4, a rotating gear 5, an adjustment rod 6, a kettle body 7, and an inner tank 8 , a top cover 9, an inner magnetic fixing plate 10 and a screen 11 are assembled.

[0028] The base 1 of the present embodiment is a common workbench, and its upper surface is processed with a circular groove for placing the kettle body 7. The left side of the kettle body 7 is fixed with a support 2 with a threaded fastener. An adjusting knob 4 is installed on the side wall of the side wall, the adjusting knob 4 is connected with the rotating gear 5 through the rotating shaft, the rotating shaft of the adjusting knob 4 drives the rotating gear 5 to rotate, and an adjusting groove is processed in the middle of the crossbeam of the bracket 2, and an adjusting groove is inst...

Embodiment 2

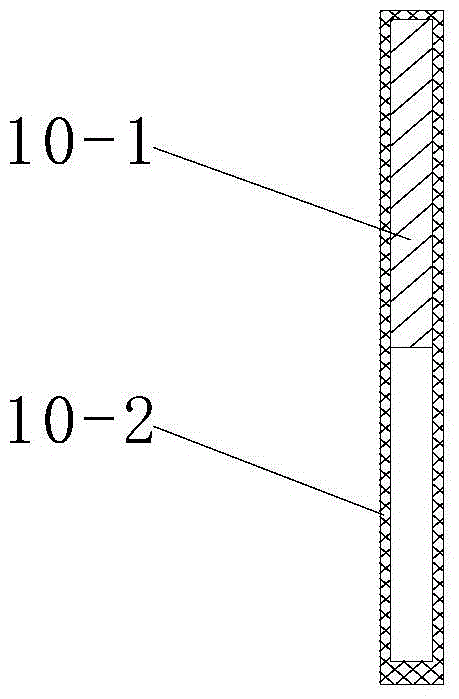

[0032] In this embodiment, the kettle body 7 is a cylindrical structure made of stainless steel, with an outer diameter of 10 cm, a height of 25 cm, and a wall thickness of 0.3 cm. A sealing top cover 9 is installed on the opening of the top of the kettle body 7 . The inner cavity of 7 is equipped with an inner container 8, the inner container 8 has a wall thickness of 0.3 cm, and an inner magnetic fixing plate 10 is arranged in the inner container 8, and the inner magnetic fixing plate 10 is adsorbed by the magnetic force generated by the outer magnetic fixing plate 3. On the inner wall of the liner 8, it is composed of an inner magnet 10-1 and a non-magnetic inner protective sleeve 10-2, see Figure 4 , the structure of the inner magnet 10-1 is adapted to the structure of the outer magnetic fixing plate 3, and it is processed into an arc surface structure adapted to the inner wall structure of the liner 8, with a central angle of 45°, a radius of curvature of 9.2cm, and an ax...

Embodiment 3

[0036] In this embodiment, the kettle body 7 is a cylindrical structure made of stainless steel, with an outer diameter of 10 cm, a height of 25 cm, and a wall thickness of 0.3 cm. A sealing top cover 9 is installed on the opening of the top of the kettle body 7 . The inner cavity of 7 is equipped with an inner container 8, the inner container 8 has a wall thickness of 0.3 cm, and an inner magnetic fixing plate 10 is arranged in the inner container 8, and the inner magnetic fixing plate 10 is adsorbed by the magnetic force generated by the outer magnetic fixing plate 3. On the inner wall of the liner 8, it is made up of an inner magnet 10-1 and a non-magnetic inner protective cover 10-2, the structure of the inner magnet 10-1 is adapted to the structure of the outer magnetic fixing plate 3, and it is also processed to be compatible with The inner wall structure of the liner 8 is an arc surface structure, the central angle of which is 90°, the radius of curvature is 9.3 cm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com