Membrane unit with scrubbing mechanism and water purifier using the same

A membrane module and water purifier technology, applied in water purifiers and household drinking water treatment fields, to achieve the effects of preventing biological pollution, simple system, and high water recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

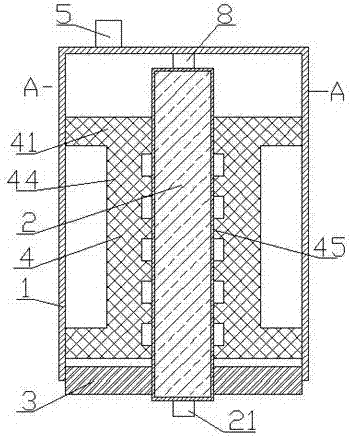

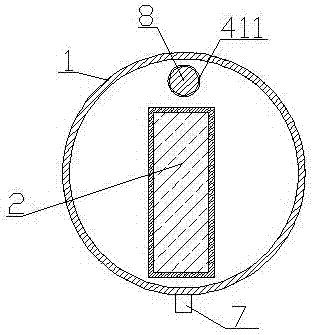

[0089] Such as figure 1 and figure 2As shown, the membrane assembly device involved in the present invention mainly includes a housing 1, a membrane element 2, a connecting body 3 and a scrubbing part 4; Part 4, the upper end of the membrane element 2 and the scrubbing part 4 are encapsulated by the casing 1, a water inlet 5 and a water outlet 6 are provided on the casing 1, and the pure water outlet 21 is located at the bottom of the membrane element 2 from the connecting body 3 Stretch out, the aqueous solution flows in from the water inlet 5, flows out from the water outlet 6, and pure water flows out from the pure water outlet 21.

[0090] In this embodiment, the volume of the housing 1 is 6 liters, and the inner top of the housing 1 is provided with a boss 8 , and the scrubbing part 4 is provided with a liquid channel 411 matching it.

[0091] In this embodiment, the length, width, and height of the membrane element 2 are respectively 300mm, 200mm, and 3mm. The polyami...

Embodiment 2

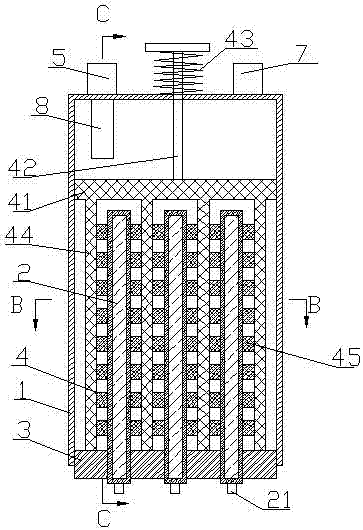

[0098] Such as Figure 3 to Figure 5 As shown, another membrane assembly with a scrubbing mechanism involved in the present invention mainly includes a housing 1, a three-plate membrane element 2, a connecting body 3, a piston 41, a piston rod 42, a spring 43, fins 44 and a wiping brush 45. The membrane element 2 is set in the casing 1 along the vertical direction. The casing 1 and the membrane element 2 are connected on the connecting body 3 to form a whole. The piston rod 42 is set on the top of the casing 1. The spring 43 is the same as the piston rod 42 The shaft is socketed and installed; the membrane unit has a water inlet 5, a water outlet 6, a clean water outlet 21 and a cleaning agent injection port 7.

[0099] The shell 1 is a hollow cylindrical thin-walled pressure vessel with one end closed, with a volume of 6 liters; the side wall of the shell 1 has a boss 8 and two linear raised parts 9 extending in the vertical direction; the raised parts 9 also have It acts as...

Embodiment 3

[0106] Such as Figure 6 As shown, the water purifier involved in the present invention includes a pretreatment unit 51, a water pump 52, a membrane unit 53 with a scrubbing mechanism, a valve 54, an electric control system 55, a pure water collection unit 56, a one-way valve 57, and a pressure sensor 58 , a flow sensor 59, a conductivity probe 60 and a domestic water valve 61; the pretreatment unit 51 is in communication with the tap water inlet, the pretreatment unit 51, the water pump 52, the membrane unit 53 with a scrubbing mechanism, and the valve 54 are sequentially connected in series, and the pure water The collection unit 56 is connected to the pure water outlet of the membrane assembly 53 with a scrubbing mechanism, the water pump 52 is connected in parallel with a one-way valve 57, and a pressure sensor 58 and a conductivity probe are respectively arranged between the membrane assembly 53 with a scrubbing mechanism and the valve 54 60, the flow sensor 59 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com