Lithium iron phosphate anode materials of three-dimensional conductive network structure and preparation method thereof

A technology of lithium iron phosphate and network structure, which is applied in the field of lithium iron phosphate cathode material and its preparation, can solve the problems such as the reduction of specific capacity and tap density, and the inability to form an effective continuous conductive network.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

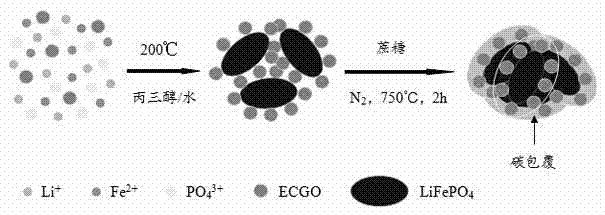

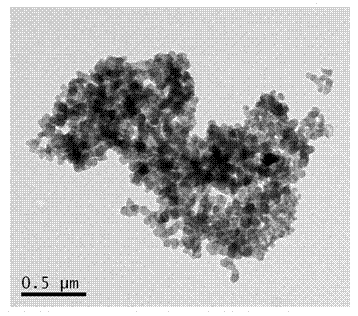

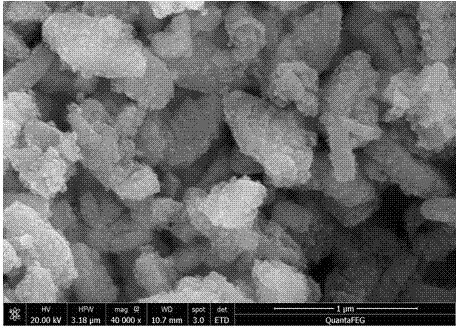

[0035] Weigh 3.36 g LiOH·H 2 O was dissolved in 2000 mL deionized water, and a 0.04 M LiOH solution was prepared, and spectroscopically pure graphite plates were used as the cathode and anode, respectively, and the current density was 25 mA cm -1 , electrolyzed for 12 hours, and the precipitate obtained by electrolysis was centrifuged at 10,000 rpm and washed twice with water, and then dried at 100°C. The results of transmission electron microscopy observations are as follows: figure 2 As shown: the obtained ECGO has a nearly spherical structure; the results of infrared spectroscopy and nuclear magnetic resonance detection show that the obtained ECGO has a certain degree of oxidation, and the surface has a large number of oxygen-containing functional groups such as hydroxyl, aldehyde and carboxyl groups. The oxygen content of the ECGO obtained by the electrochemical oxidation is less than 10%, and its resistivity measured by four probes is 4 Ω cm, which has good conductivity...

Embodiment 2

[0040] Weigh 1.68 g LiOH·H 2 O was dissolved in 2000 mL deionized water, and a 0.02 M LiOH solution was prepared, and spectrally pure graphite plates were used as the cathode and anode, respectively, with a current density of 30 mA cm -1 , electrolyzed for 24 hours, and the precipitate obtained by electrolysis was centrifuged at 10,000 rpm and washed twice with water, and then dried at 100°C. Similar to Example 1, transmission electron microscope observation shows that the obtained ECGO has a nearly spherical structure; infrared spectrum and nuclear magnetic resonance detection results show that the obtained ECGO has a certain degree of oxidation, and the surface has a large number of oxygen-containing functional groups such as hydroxyl, aldehyde and carboxyl groups. The oxygen content of the ECGO obtained by the electrochemical oxidation is less than 10%, and its resistivity measured by four probes is 6 Ω cm, which has good conductivity and hydrophilicity.

[0041] Measure 1...

Embodiment 3

[0045] Weigh 0.84 g LiOH·H 2 O was dissolved in 2000 mL deionized water, and a 0.01 M LiOH solution was prepared, and spectroscopically pure graphite plates were used as the cathode and anode respectively, and the current density was 35 mA cm -1 , electrolyzed for 36 hours, the precipitate obtained by electrolysis was centrifuged at 10000 rpm and washed twice with water, and the precipitate obtained was dried at 100 °C. Similar to Example 1, transmission electron microscope observation shows that the obtained ECGO has a nearly spherical structure; infrared spectrum and nuclear magnetic resonance detection results show that the obtained ECGO has a certain degree of oxidation, and the surface has a large number of oxygen-containing functional groups such as hydroxyl, aldehyde and carboxyl groups. The oxygen content of the ECGO obtained by the electrochemical oxidation is less than 10%, and its resistivity measured by four probes is 8 Ω cm, which has good conductivity and hydroph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com