Tuyere small sleeve

A technology of small tuyere cover and air outlet, applied in the direction of tuyere, can solve the problems of large difference in expansion coefficient and easy to fall off, and achieve the effect of improving the service life, not easy to fall off, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

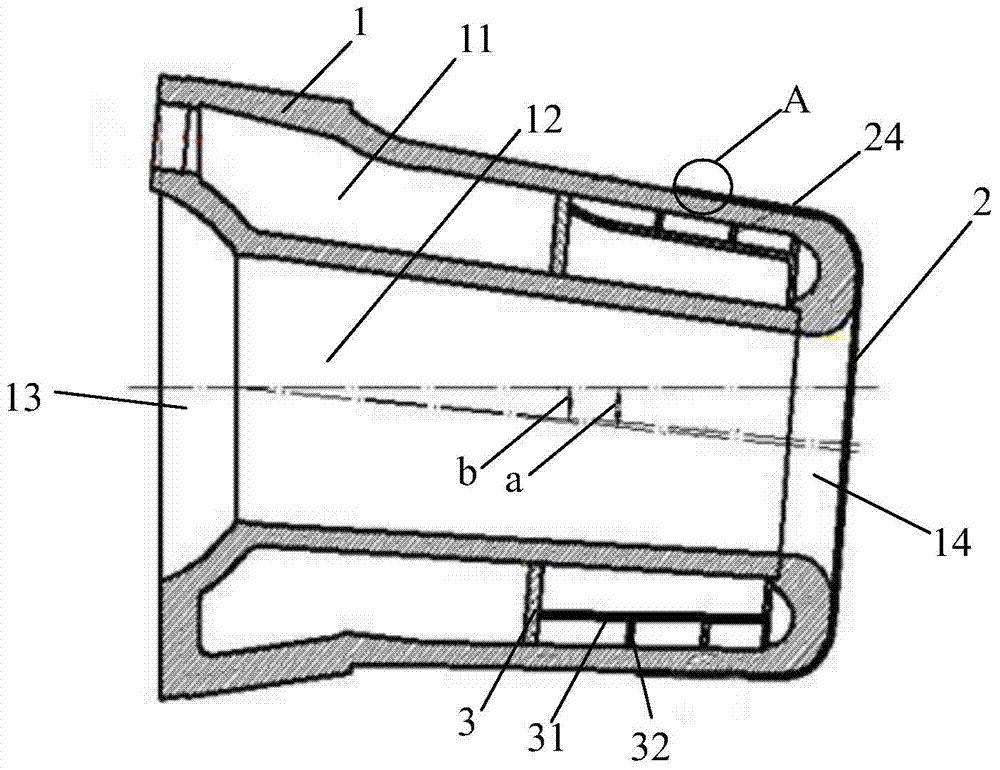

[0043] Such as figure 1 Shown, be a kind of tuyere small cover that the present invention proposes, and it comprises:

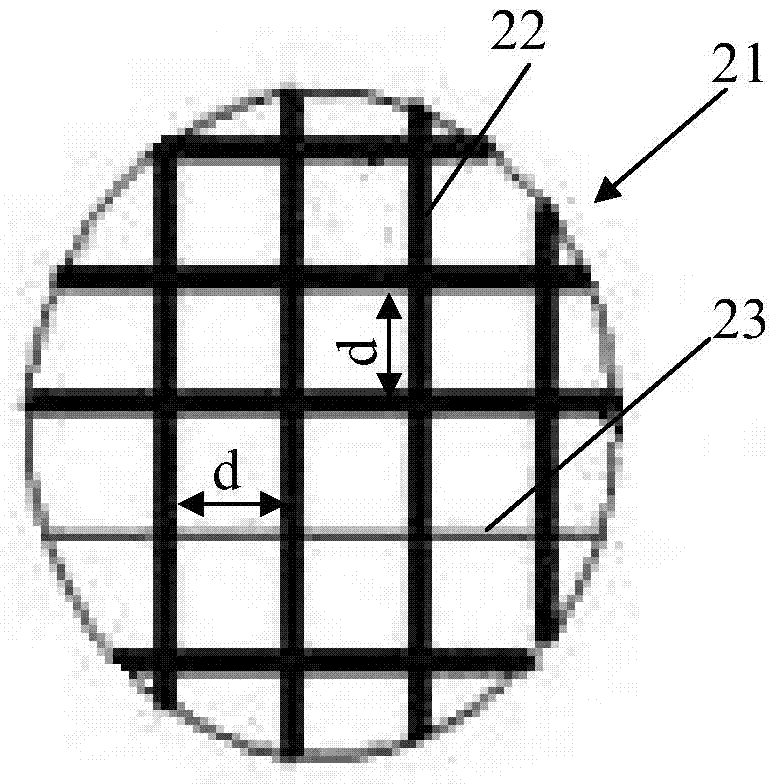

[0044]Body 1, which is an annular body with a hollow side wall 11, and an air supply channel 12 is formed inside the annular body; one end of the body 1 is an air inlet 13, and the other end is an air outlet 14; the grid cover 2 is set on the body Outside the air outlet 13 of 1, the grid cover 2 extends along the outer wall of the body 1, and the extension of the grid cover 2 forms a mesh protective layer frame 21 on at least a part of the outer wall of the body 1, so as to cover at least a part of the outer wall of the body 1 A protective layer 24 is formed on the body 1, that is, a protective layer 24 is formed on a part or the entire outer wall of the body 1; the mesh protective layer frame 21 is composed of a plurality of cells, and in the state of blast furnace production, liquid substances such as slag iron in the furnace will into each unit cell of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com