A kind of superhydrophilic silicone hydrogel contact lens and treatment method

A silicone hydrogel and contact lens technology, applied in glasses/goggles, instruments, optics, etc., can solve the difficulties in the selection of coating materials, the difficulty of coating uniformity and physiological performance factors, and the increased complexity of contact lens manufacturing, etc. problem, to achieve the effect of comfortable hand feeling, soft lens and long-lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A kind of superhydrophilic silicone hydrogel contact lens of the present invention is made up of following components according to mass fraction:

[0056] Silicon-containing monomer: 20-50%;

[0057] Hydrophilic monomer: 40~70%;

[0058] Hydrophilic polymer: 5-20%;

[0059] Initiator: 0.1~1%;

[0060] Cross-linking agent: 1-5%.

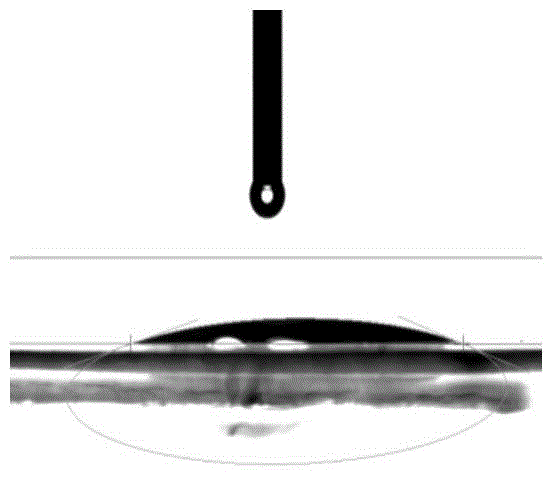

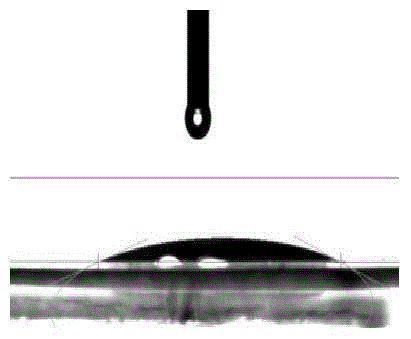

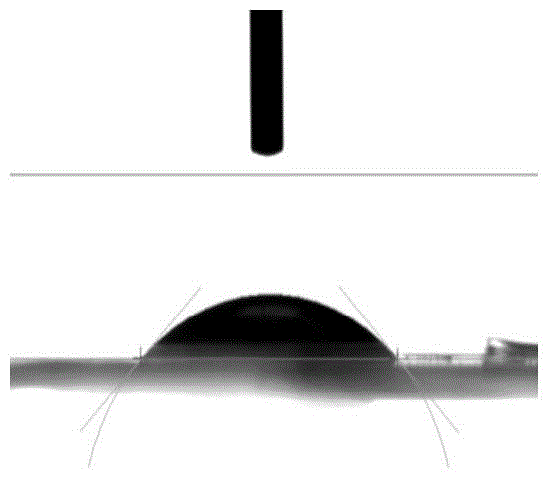

[0061] The reason why the combination of the above substances has superhydrophilicity is that the hydrophilic high molecular polymer does not participate in the reaction, but because the hydrophilic high molecular polymer has a linear structure, it can move freely in the hydrogel network formed by polymerization. In this way, part of the hydrophilic polymer will migrate to the surface, thereby improving the hydrophilicity of the silicone hydrogel surface.

[0062]During the use of the super-hydrophilic lens prepared above, the hydrophilic polymer will gradually separate from the lens due to movement, so that the lens becomes non-hydrophilic...

Embodiment 2

[0071] A superhydrophilic silicon hydrogel contact lens is characterized in that the contact lens is composed of the following components according to mass fraction:

[0072] Silicon-containing monomer: 20-50%;

[0073] Hydrophilic monomer: 40~70%;

[0074] Hydrophilic polymer: 5-20%;

[0075] Initiator: 0.1~1%;

[0076] Cross-linking agent: 1~5%;

[0077] Auxiliary: 0.1~0.5%;

[0078] The auxiliary agent is any one or a combination of colorants, ultraviolet absorbers and processing aids.

[0079] As a preference, in the above-mentioned superhydrophilic silicone hydrogel contact lens, the selection of silicon-containing monomer, hydrophilic monomer, hydrophilic high molecular polymer, initiator and crosslinking agent is the same as that in Example 1. Examples of silicon-containing monomers are methyl-bis(trimethylsiloxy)-silylpropyl glyceryl methacrylate, bis(trimethylsiloxy)propyl methacrylate, methacrylic acid Any one or any combination of pentamethyldisiloxane esters....

Embodiment 3

[0082] A method for treating a superhydrophilic silicone hydrogel contact lens, comprising the following process: soaking the silicone hydrogel contact lens in an aqueous solution of a hydrophilic high molecular polymer with a mass concentration of 10-20%, and heating the contact lens at 70-90 ℃ for more than 8 hours, and then gradually cooled to 15-25 ℃ to obtain the treated silicone hydrogel contact lens.

[0083] In this embodiment, the silicone hydrogel contact lens can be the superhydrophilic silicone hydrogel contact lens described in Example 1, or the superhydrophilic silicone hydrogel contact lens described in Example 2.

[0084] During the use of the original super-hydrophilic lens, the hydrophilic polymer will gradually separate from the lens due to movement, so that the lens becomes non-hydrophilic again. After being treated by the method of this embodiment, some of the polymers that move out of the lens network are in the lens, and some are on the surface of the le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com