Method and production equipment for preparing glutinous rice flour through water milling method

A production device and technology of glutinous rice flour, applied in food preparation, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of increasing the manufacturing cost of glutinous rice flour, loss of glutinous rice flour, waste of water resources, etc., and achieve simple structure , save water, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in combination with specific embodiments.

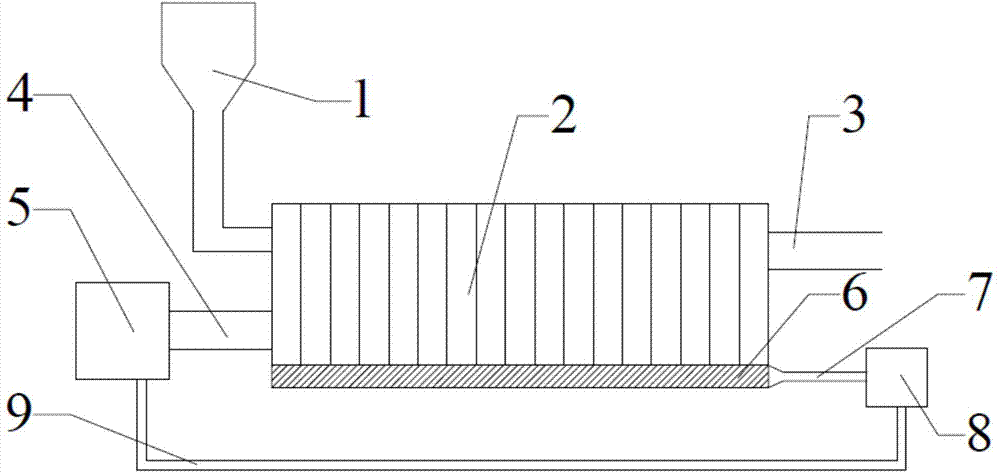

[0029] Production equipment for preparing glutinous rice flour by water milling method, such as figure 1 As shown, it includes a feeding cylinder 1, the feeding cylinder 1 is connected with a water mill device 2, the two sides of the water mill device are respectively provided with a discharge pipe 3 and a water inlet pipe 4, the water inlet pipe 4 is connected with a water tank 5, and the lower end of the water mill device 2 is arranged There is a water collection tank 6, and the water collection tank 6 is connected with a filter device 8 through a drain pipe 7, and the filter device 8 is connected to the water tank 5 through a recovery pipe 9.

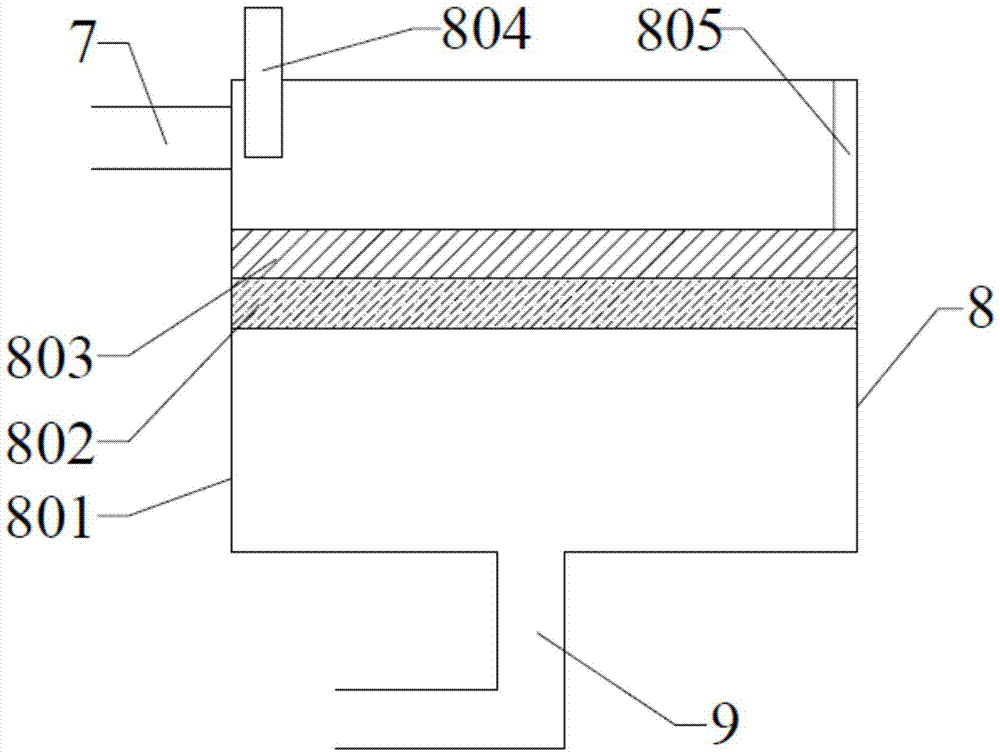

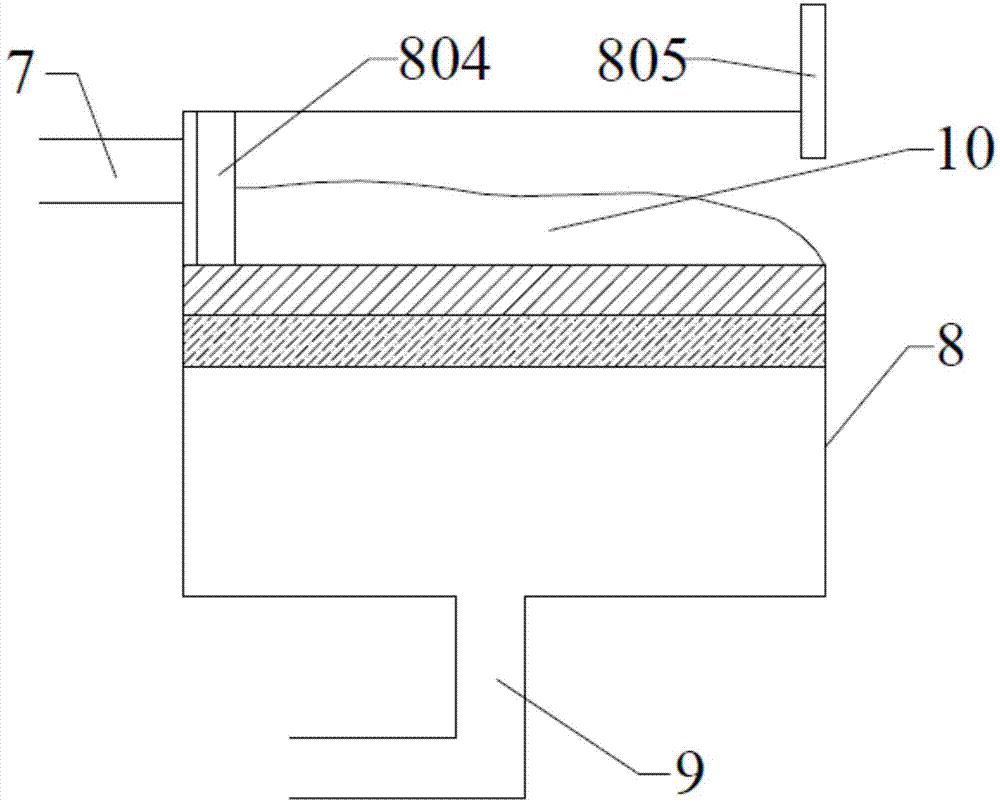

[0030] Such as figure 2 As shown, the filter device 8 includes a filter box 801, and the drain pipe 7 is arranged on one side of the upper end of the filter box 801; the inside of the filter box 801 is sequentially provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com