Automatic storage and storage device and method for plate production line

A production line, in-out and out-of-warehouse technology, applied in storage devices, transportation and packaging, etc., can solve the problems of large occupied space, low production efficiency, unsafe, etc., and achieve the effect of small occupied space, improved safety factor, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

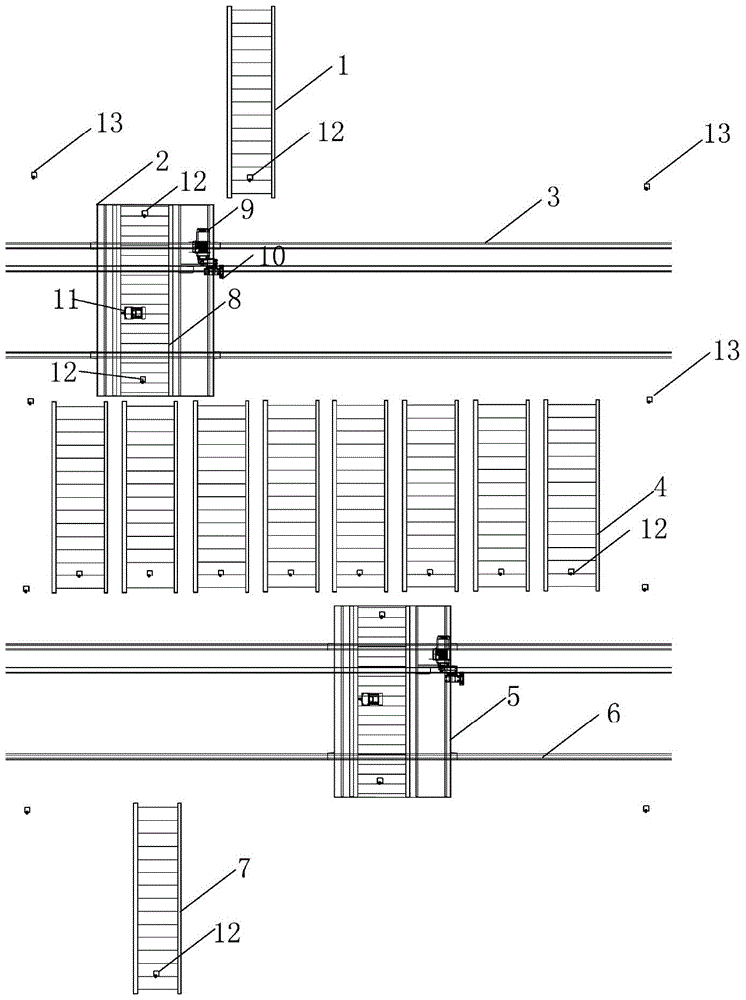

[0035] Such as figure 1 As shown, the automatic warehousing device for the plate production line disclosed in the embodiment of the present invention is arranged between the processing equipment of the two processes, and sequentially includes the plate output area, the first conveying trolley (that is, the entry Storage trolley 2), storage area, the second conveying trolley (namely outbound trolley 5) and plate input area, and the main controller for controlling the equipment. There is a first roller conveyor 1 in the plate output area, and the first roller conveyor 1 is located at the end of the upstream processing equipment (such as docking with the cutting saw receiving equipment), which is used to store and transport the codes output by the upstream processing equipment. Stacked boards. A plurality of second roller conveyors 4 are arranged side by side in the warehouse location area, and each roller conveyor represents a warehouse location for storing and conveying plates...

Embodiment 2

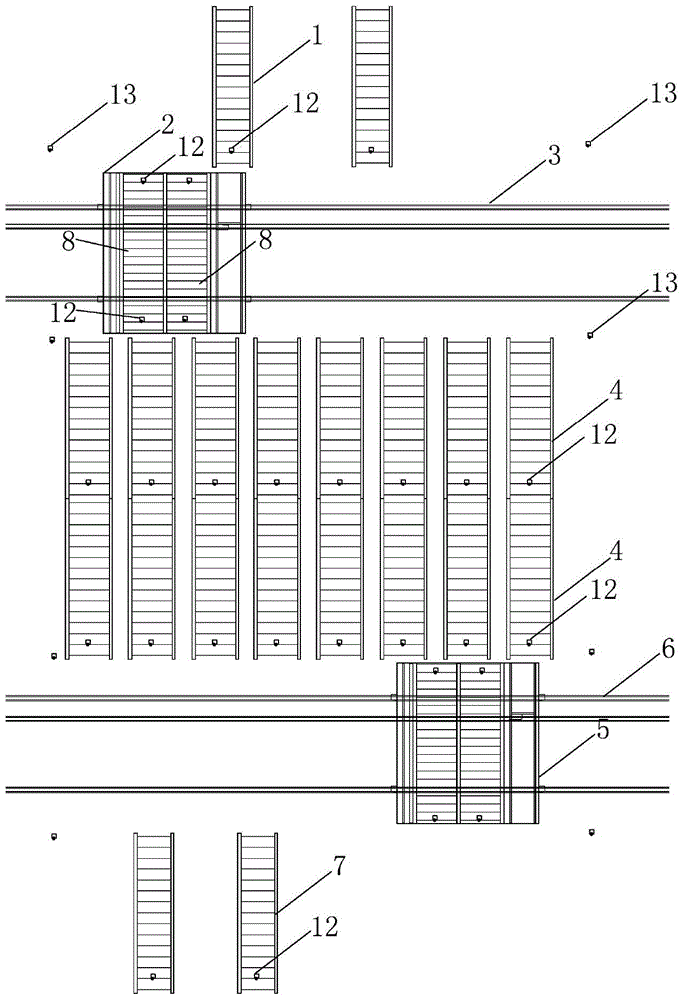

[0041] Such as image 3 As shown, the automatic warehouse-in and out-loading device for the plate production line disclosed in the embodiment of the present invention, compared with Embodiment 1, expands the storage capacity of the plate output area, the storage area, and the plate input area, and improves the single time of the trolley. Transportation capacity (traveling motor and roller motor are not shown in the figure), two first roller conveyors 1 are installed in the plate output area, which are respectively located at the ends of the two output ports of the upstream processing equipment, or the output ports of different processing equipment . The plate input area is also provided with two third roller conveyors 7, which are respectively located at the beginnings of the two input ports of the downstream processing equipment, or at the input ports of different processing equipment. It can be understood that this embodiment only illustrates two sets, and the specific numb...

Embodiment 3

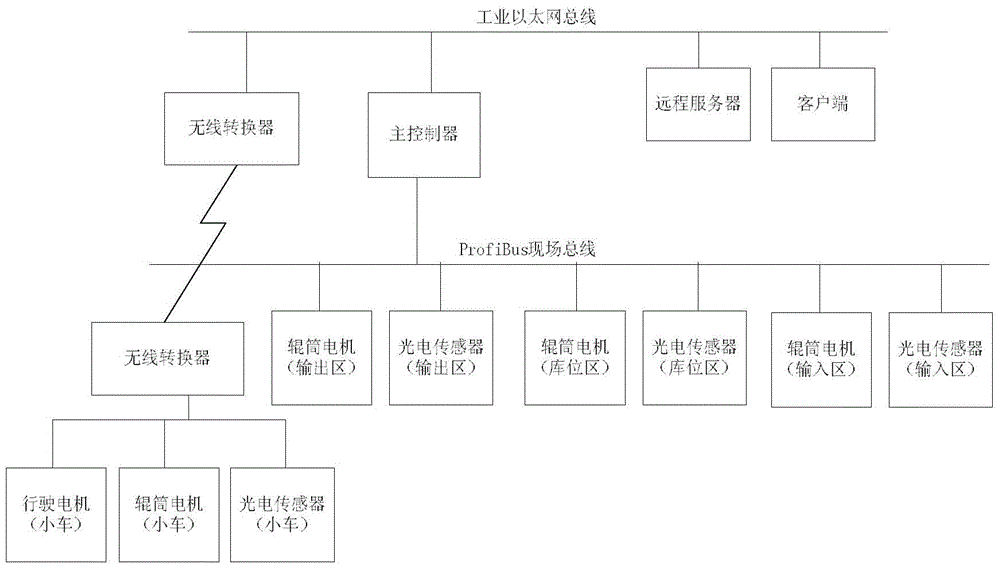

[0043] Such as Figure 4 As shown in the embodiment of the present invention, the storage and storage control method for the automatic storage and storage device of the plate production line disclosed in the embodiment 1, the main controller receives instructions from the remote application server, converts the instructions, and then sends them to the storage device Each executive motor, and receive the information fed back by each sensor to complete the closed-loop control. At the same time, the main controller also feeds back the execution result to the remote application server. This method mainly involves basic equipment control and process control, and can be applied to semi-automatic production or fully automatic production scheduling system manually controlled by the client interface. The storage and storage control method of the present embodiment mainly includes the following steps:

[0044] (S101) Plate output: After receiving the output command from the main contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com