3D-printed drone frame and drone

A 3D printing and machine frame technology, applied in the field of drones, can solve the problems affecting the signal transmission quality of each module, affecting the flight safety of drones, inconvenient installation and disassembly, etc., to achieve reasonable design layout, simple and stable structure , Easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The implementation structure of the present invention will be described below in conjunction with the accompanying drawings.

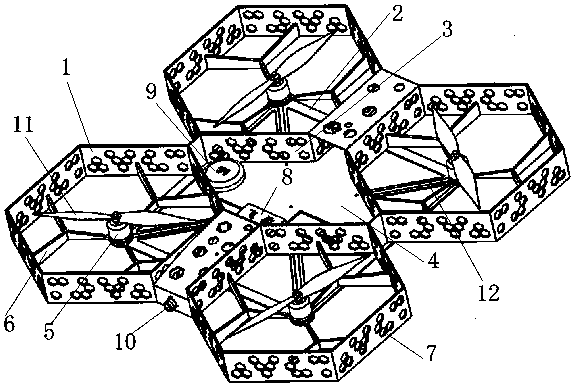

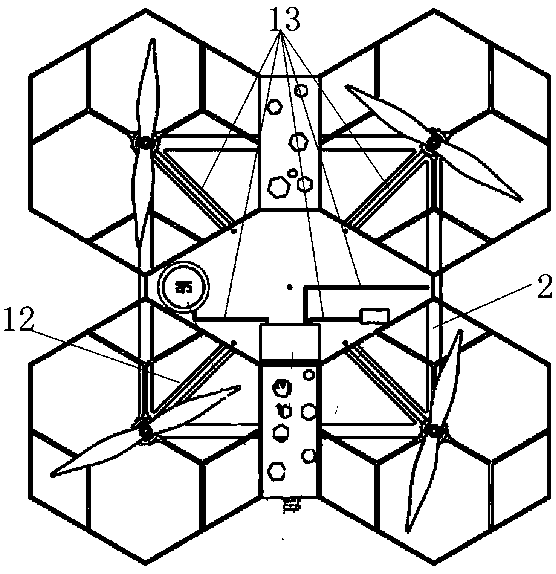

[0015] Such as figure 1 and figure 2 As shown, the 3D printing drone frame of the present invention includes four regular hexagonal rotor guard arms 1 and a rectangular reinforcement frame 2; connecting plates are arranged between the regular hexagonal rotor guard arms 1, and four regular hexagonal rotor guard arms The rotor guard 1 is integrally formed and connected with the connecting plate. The central position of the UAV frame composed of four regular hexagonal rotor guards 1 is a rhombus cavity 3, and the bottom of the rhombus cavity 3 is provided with a fixing bracket matching the shape of the rhombus cavity 3. Bottom plate 4; regular hexagonal rotor arm 1 is internally provided with reinforcement beam 6 for fixedly installing motor 5, and reinforcement beam 6 divides regular hexagonal rotor arm 1 into several regular hexagons and rhombu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com