Structure of a motor-car type pure electric BRT road train

A road train, pure electric technology, applied in the direction of motor vehicles, electric power devices, tractor-trailer combination, etc., can solve the problems of increasing the difficulty of the driver's operation, increasing the width of the channel circle, and large steering wheel angle, etc., to achieve the goal of carrying The effects of capacity improvement, reduced turning channel circle width, and increased carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments of the present invention will be further described in conjunction with the accompanying drawings.

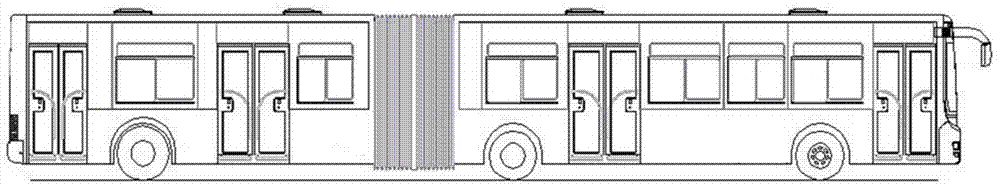

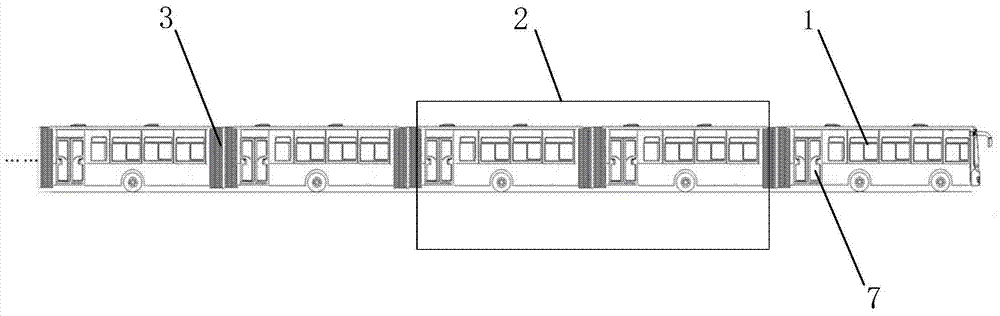

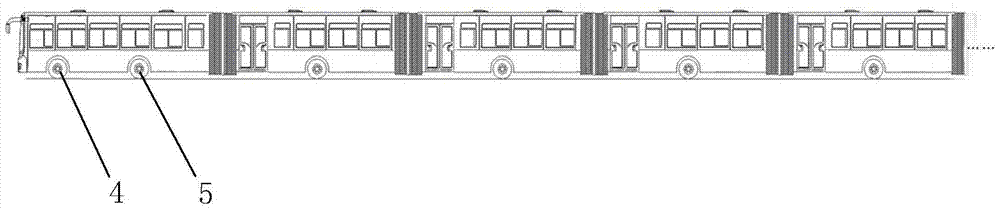

[0038] The train structure is composed of a guiding locomotive 1 and one or more pairs of power carriages 2, wherein each pair of power carriages 2 is composed of two sections of single carriages. The guide locomotive 1 and the pair of power carriages 2, and between two adjacent pairs of power carriages 2 are connected by a single ordinary traction hinge 9, and the middle of each pair of power carriages 2 is connected by an upper hinge 10 and a lower hinge 11 Connected so that the joint of the hinge plate is allowed to swing left and right in the horizontal direction, but cannot move in the vertical direction. The train hinge is covered with a soft canopy 3.

[0039] The guiding locomotive 1 is a double bridge structure, and each group of power carriages has two axles, which are respectively arranged in the middle of the two sections of single ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com