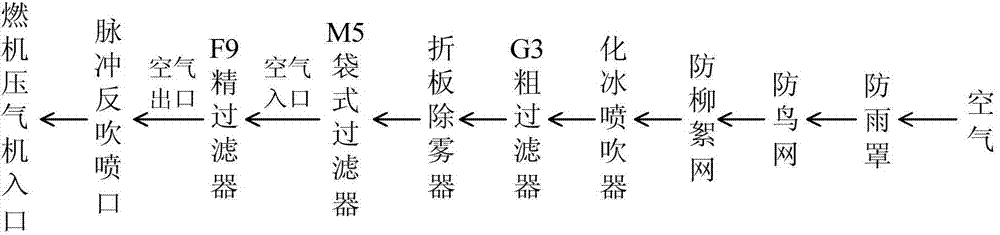

Refined filtration drum dedusting device and refined filtration drum dedusting method for inlet air filtering system of gas turbine

A technology of filtration system and dust removal device, applied in separation methods, dispersed particle filtration, chemical instruments and methods, etc., can solve the problems of inability to clean the fine filter cartridge, shortening the service life of the fine filter cartridge, and increasing the cost of power generation, etc. The effect of improving safety and stability, improving power generation efficiency, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

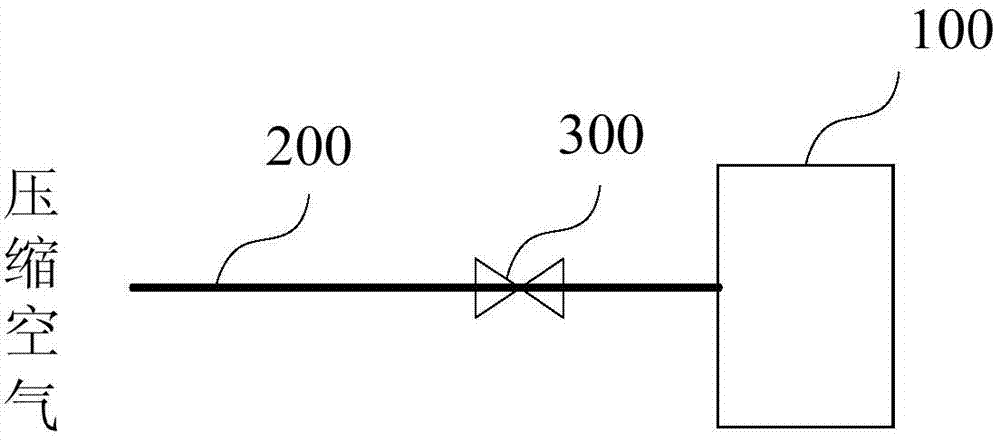

[0025] see figure 2 , the fine filter cartridge dust removal device of the gas engine air intake filter system provided in this embodiment includes a sealing cover 100 , a compressed air pipeline 200 and a blowback valve 300 . Among them, the sealing cover 100 is mainly used to cover the air outlet end of the fine filter cartridge to seal the air outlet of the fine filter cartridge. , disc shape and other arbitrary shapes, as long as the air outlet of the fine filter cartridge can be sealed; the compressed air pipeline 200 communicates with the sealing cover 100, and the blowback valve 300 is arranged on the compressed air pipeline 200 to control the direction of the compressed air pipeline 200. Compressed air is sprayed into the fine filter cartridge for back blowing and dedusting.

[0026] When in use, you only need to cover the sealing cover 100 on the air outlet end of the fine filter cartridge, and then open the blowback valve 300, the compressed air in the compressed a...

Embodiment 2

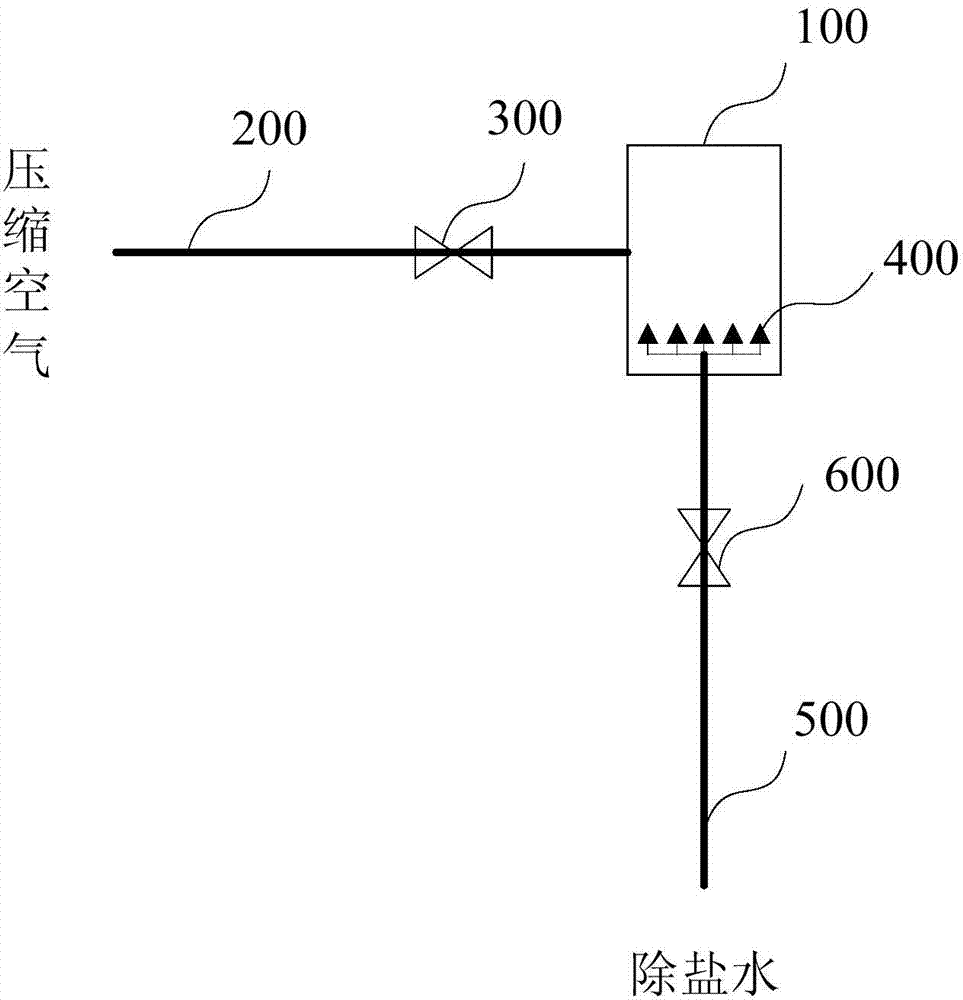

[0030] see image 3 , the fine filter cartridge dust removal device of the gas engine air intake filter system provided in the second embodiment of the present invention, on the basis of the first embodiment, further includes an atomizing nozzle 400 , a desalinated water pipeline 500 and a valve 600 . Wherein, the atomizing nozzle 400 is arranged inside the sealing cover 100 and connected with the desalinated water pipeline 500 . The valve 600 is arranged on the desalted water pipeline 500 to control the desalted water pipeline 500 to spray desalted water into the inside of the fine filter cartridge after sealing (that is, behind the air outlet end cover seal cover 100 of the fine filter cartridge), and through the atomization nozzle The 400 atomizes the desalinated water, humidifies the injected compressed air, and realizes cleaning and dedusting. The valve 600 can be a manual valve or a solenoid valve.

[0031] Desalinated water is a kind of water with a very high cleanlin...

Embodiment 3

[0035] see Figure 4 , the arrow indicates the direction of liquid or gas flow. The dust removal device for the fine filter cartridge of the air intake filter system of the gas turbine provided by the third embodiment of the present invention, on the basis of the second embodiment above, further includes a dust collection device, and the dust collection device includes a suction cylinder 700 and a vacuum cleaner 800 . The suction cylinder 700 is adapted to the shape of the fine filter cartridge 10 , with one end open and covered on the air inlet end of the fine filter cartridge 10 . The suction cylinder 700 is provided with one or more suction holes, and the vacuum cleaner 800 is connected with the suction cylinder 700 through the suction holes, and sucks the dust on the outer surface of the fine filter cylinder from the suction port. The suction cylinder 700 can be connected with multiple vacuum cleaners 800 (three are shown in the figure).

[0036] The above-mentioned suctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com