Gas-liquid mixed booster system

A gas-liquid mixed transportation and pressurization system technology, which is applied to the compression of natural gas refueling, wellhead gas, and petroleum fields. And the effect of safety, energy saving and environmental protection pressure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

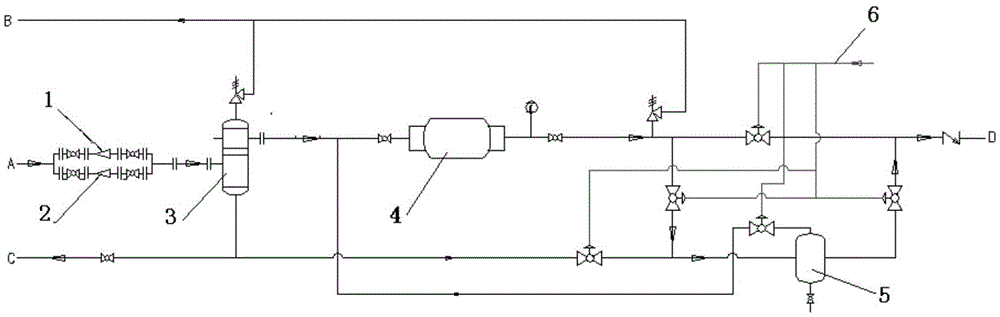

[0032] see figure 1 , shows the gas-liquid mixed delivery pressurization system of the present invention.

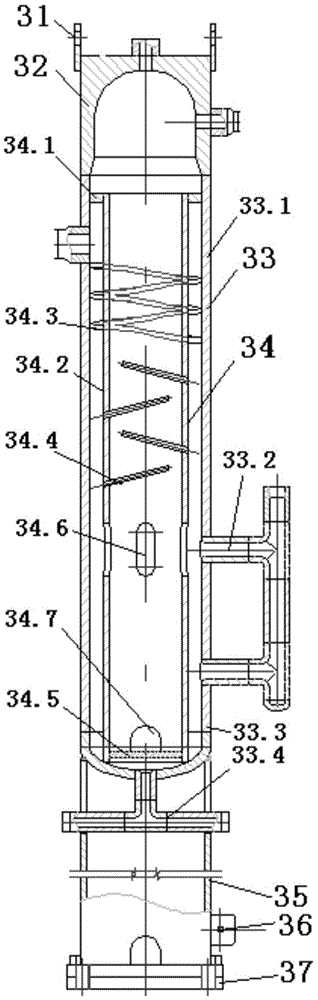

[0033] The gas-liquid mixed transport pressurization system includes a solid filter part, a gas-liquid separation part and a compression storage part, and the solid filter part is connected to the mixed transport inlet A to process the gas-liquid mixed transport components entering through the mixed transport inlet A. Filtration to avoid the entry of solids in it to damage subsequent components. The gas-liquid separation part is arranged behind the solid filter part, and its inlet is connected to the outlet of the solid filter part to receive the filtered gas-liquid mixed transport components. The compressed storage The part is arranged behind the gas-liquid separation part to compress the separated gas and store the liquid.

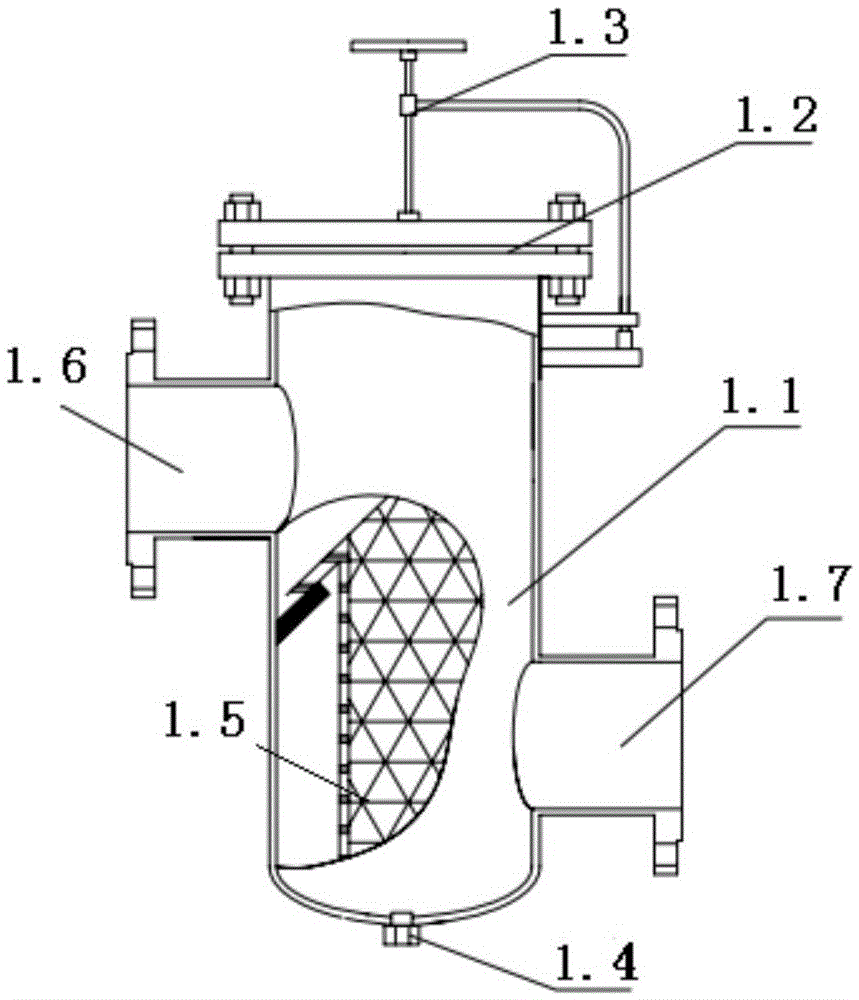

[0034] Wherein, the solid filtering part may comprise at least two groups of basket filter assemblies connected in parallel, and each basket filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com