Large-starting-torque carbon-free trolley driver

A carbon-free car and starting torque technology, which is applied in toy cars, toy transmission, toys, etc., can solve the problems of car starting difficulties, inability to start, and failure to solve the problem of car starting, and achieve convenient start and control, simple and practical structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: The outer surface of the starting disk of the driver is a circumferential surface with a constant radius along the circumferential direction.

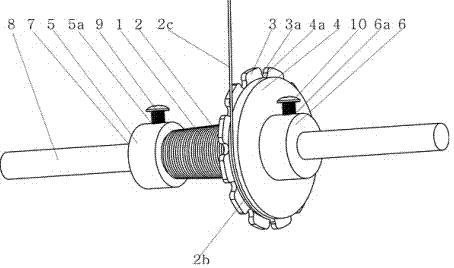

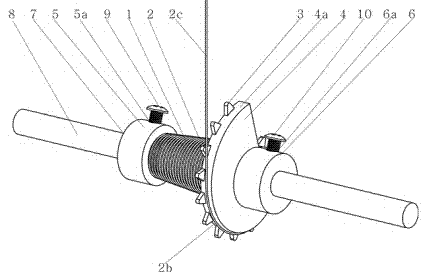

[0026] figure 1 , figure 2 Respectively, the outer edge surface 4a of the boot disk is a front view and a rear view of the disk drive along the circumferential direction and a circumferential surface with a constant radius, Figure 5 is the axonometric drawing of the drive applied to the carbon-free trolley. The driving part is composed of bobbin 1, hanging reel 3, starting plate 4, right retaining ring 5, left retaining ring 6, right screw hole 5a, left screw hole 6a and through hole 7. The bobbin 1 is a cone, and the traction wire 2 drives the driving part around the cone surface to rotate for driving. The wire hanging reel 3 is located at the left end of the bobbin 1, and is used for hanging the pulling wire lead-out end 2a. The starting disk 4 is located at the left end of the wire hanging disk 3 , and the...

Embodiment 2

[0030] Embodiment 2: The outer surface of the starting disk of the driver is a curved surface with increasing radius along the circumferential direction.

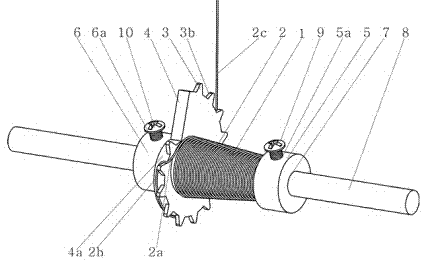

[0031] image 3 , Figure 4 It is a front view and a rear view of the driver that the outer edge surface 4a of the boot disk is a curved surface with an increased radius along the circumferential direction. The driving part is composed of bobbin 1, hanging reel 3, starting plate 4, right retaining ring 5, left retaining ring 6, right screw hole 5a, left screw hole 6a and through hole 7. The bobbin 1 is a cone, and the traction wire 2 drives the driving part around the cone surface to rotate for driving. The wire hanging reel 3 is located at the left end of the bobbin 1, and is used for hanging the pulling wire lead-out end 2a. The starting disk 4 is located at the left end of the wire hanging disk 3, and the outer surface 4a of the starting disk is an Archimedes spiral surface with an increased radius along the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com