Multi-flavor bonbon and preparation method thereof

A filling candy and multi-taste technology, which is applied in confectionary, confectionary industry, food science, etc., can solve problems such as threats to health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

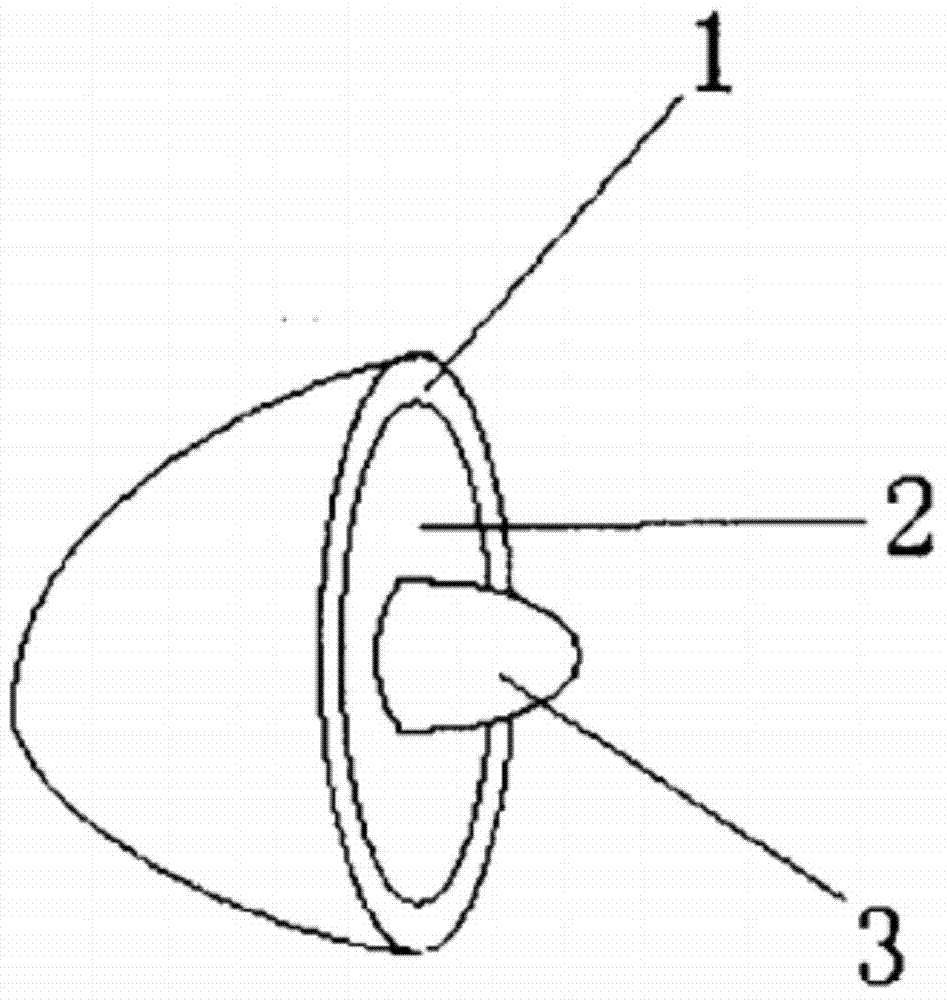

[0027] see figure 1 , a kind of multi-taste center-filled candy of the present invention comprises the sugar shell 1 of sugar product, and the sugar shell 1 is transparent hard candy or soft candy. Jujube 2 is embedded in the sugar shell 1 as the sugar core. The jujube has no seeds and has a cavity inside. The pitted jujube is 2-3.5cm long and 1.5-2.5cm in diameter. One or more delicious fruit and vegetable slurries 3 are poured into the cavity, and the fruit and vegetable slurries 3 are also mixed with rose essential oil.

[0028] A preparation method of multi-taste sandwich candy, the preparation method is as follows:

[0029] Seven mature jujubes were selected, subjected to ultra-high pressure treatment, the boost time was 15s, the pressure was raised to 400MP, the pressure holding time was 15min, the co-treatment temperature was 30°C, the depressurization time was 13s, the core was removed, and then put into the compound heating vacuum In the drying oven, adjust the vacu...

Embodiment 2

[0033] A preparation method of multi-taste sandwich candy, the preparation method is as follows:

[0034] Seven mature jujubes were selected, subjected to ultra-high pressure treatment, the boost time was 5s, the pressure was raised to 300MP, the pressure holding time was 10min, the co-processing temperature was 28°C, the depressurization time was 15s, the core was removed, and then put into the compound heating vacuum In the drying oven, adjust the vacuum degree to 50Pa and dry at 30°C for 3 hours, so that the moisture content is lower than 15%, and the desired sugar core is made.

[0035] Select the edible parts of the required fruits and vegetables, crush them, beat them with a tissue masher, add 1% rose essential oil, and process them in a colloid mill to obtain fruit and vegetable pulp; the fruit and vegetable pulp is treated with ultra-high pressure, the boost time is 15s, and the pressure is increased to 500MP, the holding time is 15min, the synergistic treatment temper...

Embodiment 3

[0038] A preparation method of multi-taste sandwich candy, the preparation method is as follows:

[0039] Seven mature jujubes were selected, subjected to ultra-high pressure treatment, the boost time was 15s, the pressure was raised to 500MP, the pressure holding time was 15min, the co-treatment temperature was 35°C, the depressurization time was 15s, the core was removed, and then put into the compound heating vacuum In the drying oven, adjust the vacuum degree to 60Pa and dry at 40°C for 1 hour, so that the moisture content is lower than 15%, and the desired sugar core is made.

[0040] Select the edible parts of the required fruits and vegetables, crush them, beat them with a tissue masher, add 0.5% rose essential oil, and process them in a colloid mill to obtain fruit and vegetable pulp; the fruit and vegetable pulp is treated with ultra-high pressure, and the boosting time is 10s. 400MP, the holding time is 12min, the co-processing temperature is 30°C, and the depressuri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com