Brake rotor fixing mechanism and installation method thereof

A technology of brake rotor and fixing mechanism, which is applied in the direction of brake actuator, manufacturing motor generator, electromechanical device, etc., can solve the problems of increased processing and installation procedures, axial movement, low reliability, etc., and achieves good application prospects , high reliability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

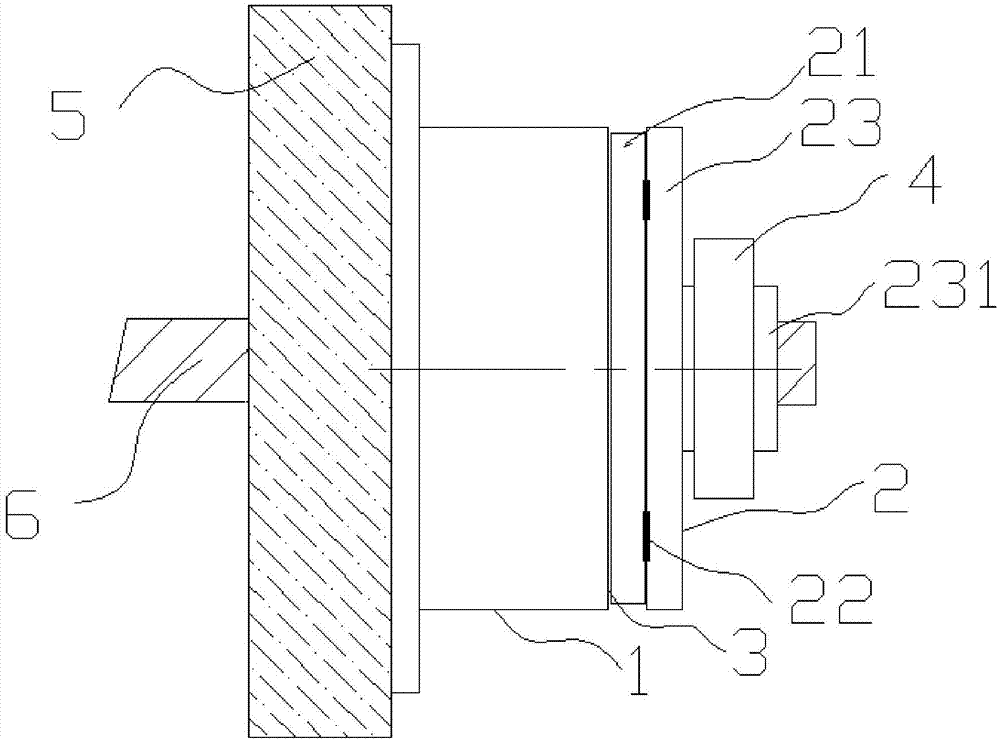

[0032] like figure 2 As shown, a brake rotor fixing mechanism includes a stator 1 fixed on the motor end cover by bolts, and a rotor 2 integrally formed with the motor shaft 6, the stator 1 and the rotor 2 are coaxially installed, and the rotor 2 Located on the outside of the stator 1, an axial gap 3 is provided between the stator 1 and the rotor 2. The rotor 2 includes an armature 21, a spring leaf 22, a flange 23 and a fastening ring 4. The armature 21 and the stator 1 The outer side of the flange 23, the spring piece 22 is arranged between the outer side of the armature 21 and the inner side of the flange 23, the flange boss 231 on the outer side of the flange 23 is socketed with the motor shaft 6, and the flange boss 231 There is an opening groove 232 on the top, and the fastening ring 4 is sleeved on the flange boss 231 to squeeze the flange boss 231 to deform a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com