Anti-drifting device for differential heat treatment, differential temperature furnace and differential heat treatment method

A technology of differential temperature heat treatment and anti-channeling, which is applied in the field of heat treatment and can solve problems such as poor hardness uniformity and manufacturing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

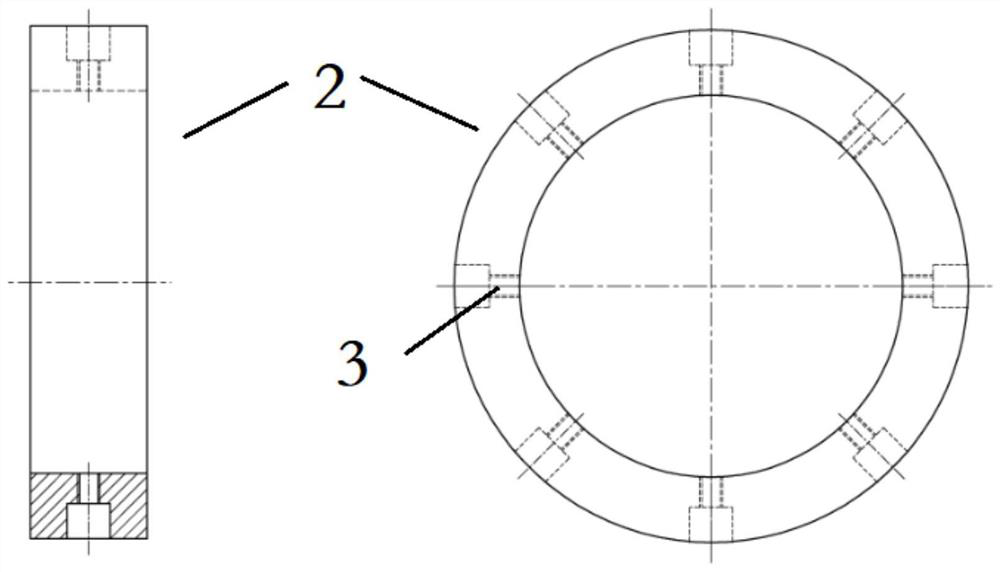

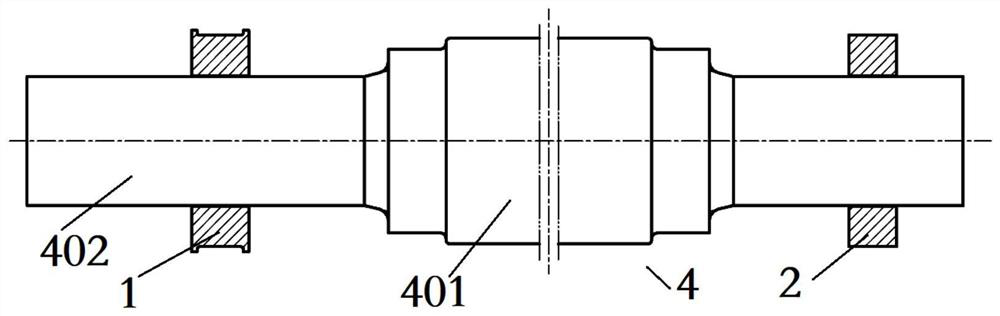

[0072] An anti-channeling device for differential temperature heat treatment of work rolls of an aluminum plate rolling mill, comprising an anti-channeling sleeve and a support sleeve, both of which are hollow cylindrical structures, and ring-shaped anti-channeling protrusions are arranged at both ends of the anti-channeling sleeve.

[0073] Both the anti-channeling sleeve and the supporting sleeve are uniformly provided with 8 threaded holes in the circumferential direction, and the anti-channeling sleeve and the supporting sleeve are fixed on the roll necks at both ends through the threaded holes with hexagon socket head screws.

[0074] The anti-channeling sleeve and the support sleeve have the same inner diameter and outer diameter. In this embodiment, the inner diameter outer diameter The axial length of the supporting wheel is 155mm, the axial length of the anti-channeling sleeve is 300mm, the height of the anti-channeling protrusion is 25mm, the width of the anti-chan...

Embodiment 2

[0076] A differential temperature heat treatment method for work rolls of an aluminum plate rolling mill. In this embodiment, the dimensions and main technical requirements of the work rolls are:

[0077] Table 1 Work roll size and hardness requirements

[0078]

[0079] Table 2 Main chemical composition of work rolls in this example (wt.%)

[0080] C Si mn Cr Ni Mo V Fe 0.30-0.70 0.40-0.80 0.40-0.80 4.50-5.50 0.20-0.80 0.40-0.80 0.10-0.50 the remaining

[0081] Step 1. Adjust the positions of the two ends of the horizontal open and close furnace body according to the length of the work roll rough machining roll body of 3975 mm.

[0082] Step 2. Install the anti-channeling sleeve and the support sleeve symmetrically on the small roll necks at both ends of the work roll. The distance between the two is 6000mm, and they are fastened with hexagon socket head screws, such as Figure 5 shown. It should be noted here that the height of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com