Liquid flow monitoring device

A monitoring device and liquid flow technology, applied in the field of sensor detection, can solve problems such as easy to be corroded, difficult to detect small flow rate, etc., and achieve the effect of accurate measurement results and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

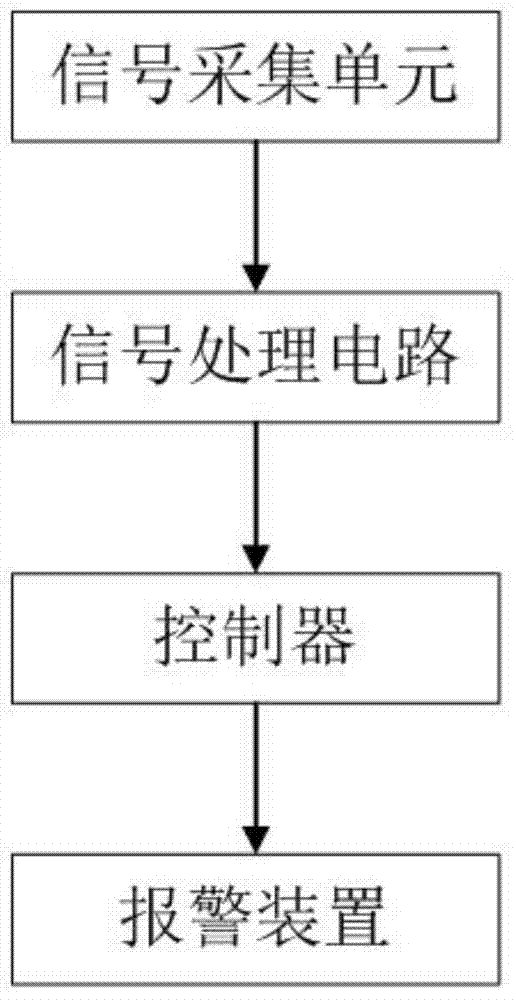

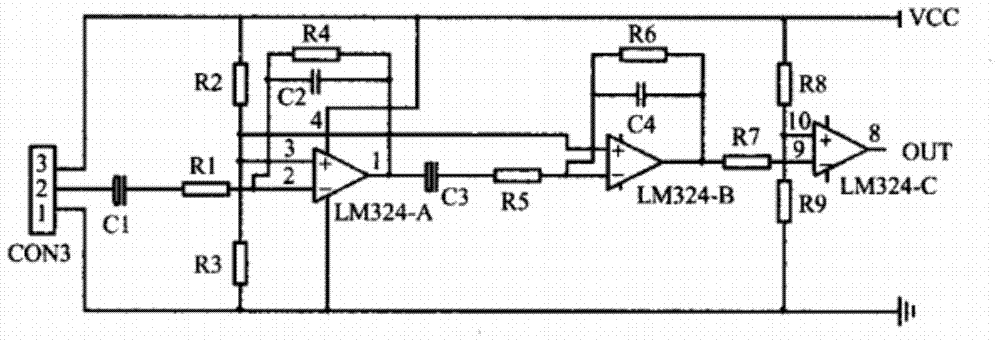

[0019] Example: figure 1 The control block diagram of the liquid flow monitoring device provided by the embodiment of the present invention, it can be clearly seen from the figure that the liquid flow monitoring device provided by this embodiment includes a signal acquisition unit, a signal processing circuit, a controller and an alarm device, wherein, The signal acquisition unit includes a turbine fixed in the water pipe and a magnetoresistive sensor, the surface of the turbine is perpendicular to the direction of liquid flow in the water pipe, and the magnetoresistive sensor for detecting the turbine speed is close to the turbine, figure 2 The schematic diagram of the signal processing of the liquid flow monitoring device provided by the embodiment of the present invention, the signal processing circuit is a three-terminal differential circuit, the signal processing circuit includes three operational amplifiers, the output terminal of the signal acquisition unit is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com