Power module thermal management device and method based on drive circuit adaptive adjustment

A technology of self-adaptive adjustment and drive circuit, applied in control/adjustment system, simulator, program control and other directions, can solve the problems of complex drive circuit, increase useless loss, etc., achieve good dynamic performance, overcome circuit impact, and ensure voltage range and the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, not for limiting the protection scope of the present invention.

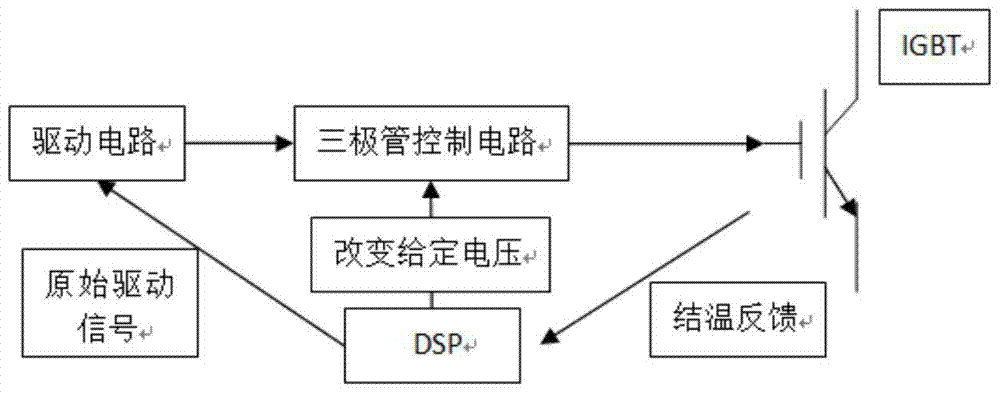

[0038] As shown in the figure, the power module thermal management device based on the adaptive adjustment of the driving circuit provided by the present invention includes a DSP analog voltage output circuit, an IBGT gate charging control loop and an IGBT gate arranged between the driving circuit and the IGBT gate. Discharge control loop;

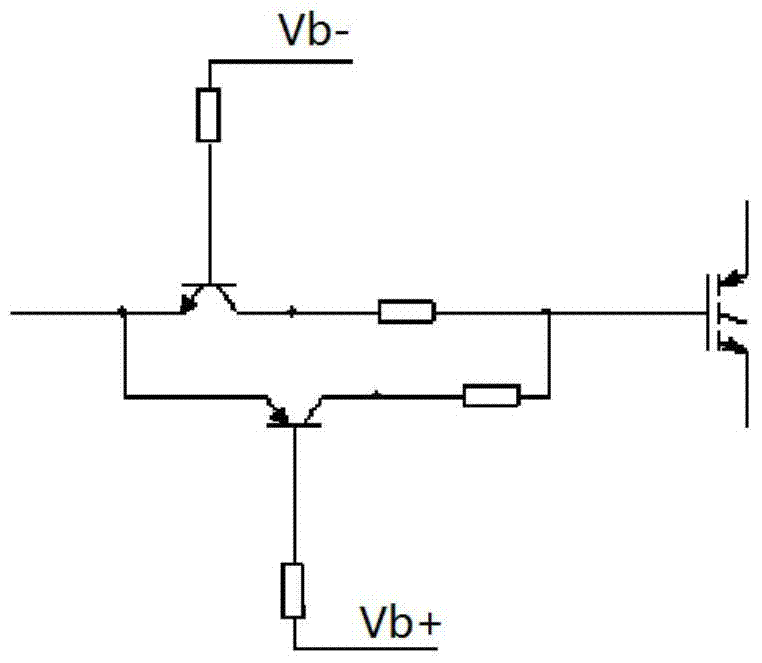

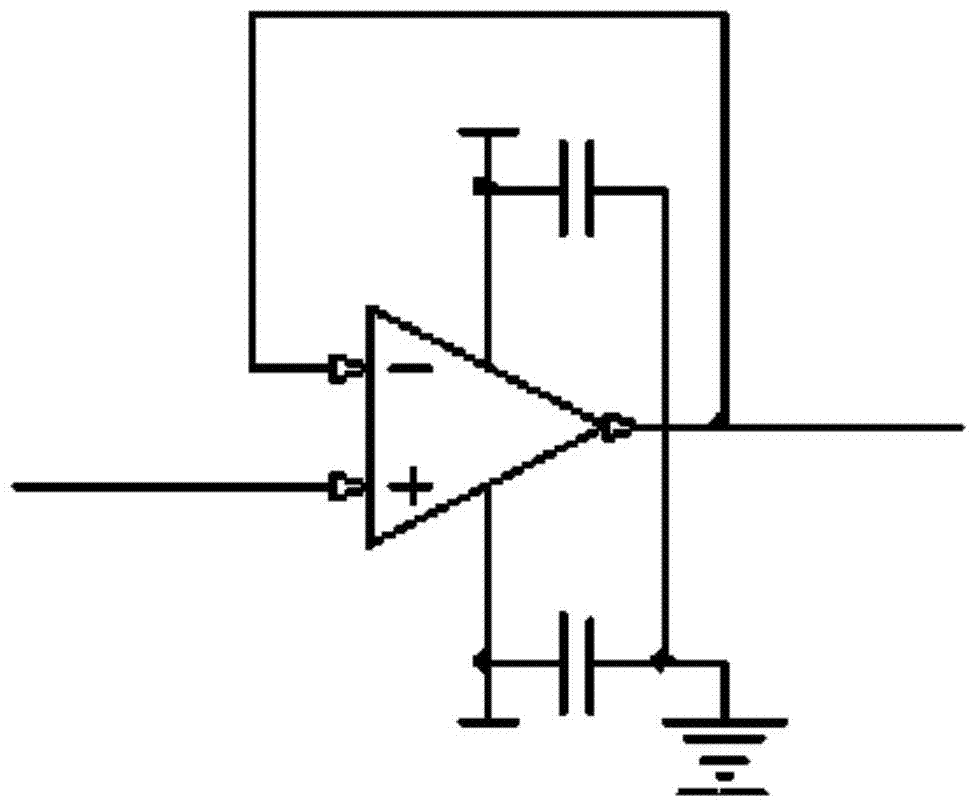

[0039] The IGBT gate charging control loop is used to provide a charging loop for the IGBT gate parasitic capacitance while controlling the peak value of the charging current; the IGBT gate discharge control loop is used to provide a discharging loop for the IGBT gate parasitic capacitance while controlling Peak discharge current; the DSP ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com