A fully automatic piston pressure gauge

A piston-type pressure gauge, fully automatic technology, applied in the direction of piston-type fluid pressure measurement, fluid pressure measurement, measuring device, etc., can solve the problems of occupying volume, reducing the accuracy of pressure output, reducing efficiency, etc., and achieve detection and calibration The effect of high quality, ensuring metering performance, and avoiding pressure deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the specific implementation of the present invention is not limited thereto.

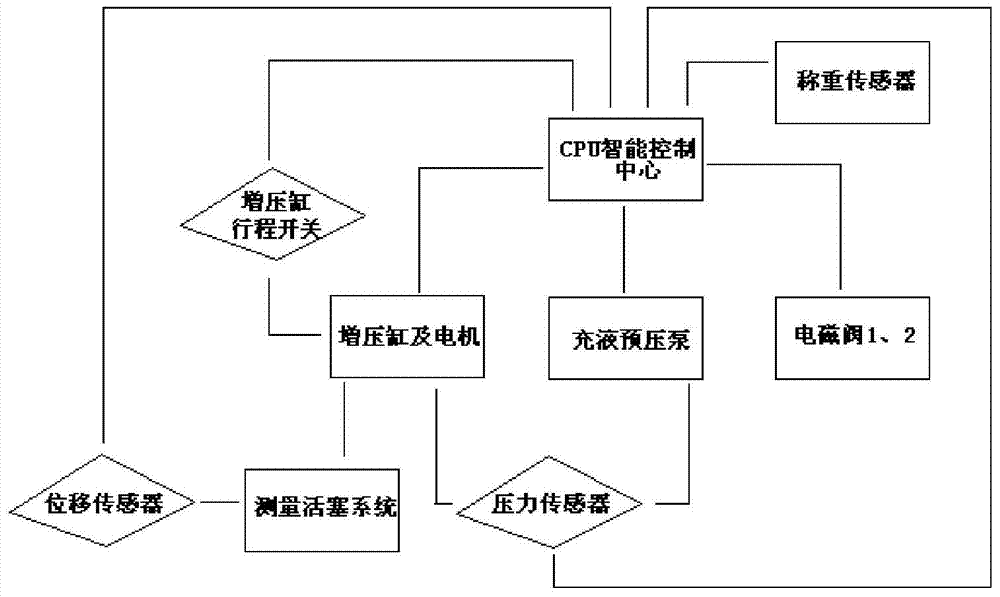

[0017] Such as figure 1 Shown is the first embodiment of a fully automatic piston pressure gauge 1 of the present invention, which includes two independent parts of an automatic pressure controller and a numerically controlled force generating device.

[0018] The pressure automatic controller consists of a pressure oil pump, an intelligent control circuit unit, a motor 1, a motor 2, a reduction box, a supercharger, a travel switch, a measuring piston system mechanism, a piston rotating mechanism, a pressure sensor, a position sensor 1, and a position sensor 2 , weighing sensor 1, weighing sensor 2, pressure output interface 1, pressure output interface 2, pressure control pipeline components, stop valve, unloading valve and shell, chassis.

[0019] The motor 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com