Crimping terminal structure for electrical appliance connector

A technology for crimping terminals and connectors, which is applied to the parts, connections, and connections where permanent deformation works in connection devices, etc., can solve the problems of high cost, slurry leakage, and increased connector production processes, and reduce production costs. , to ensure reliability and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

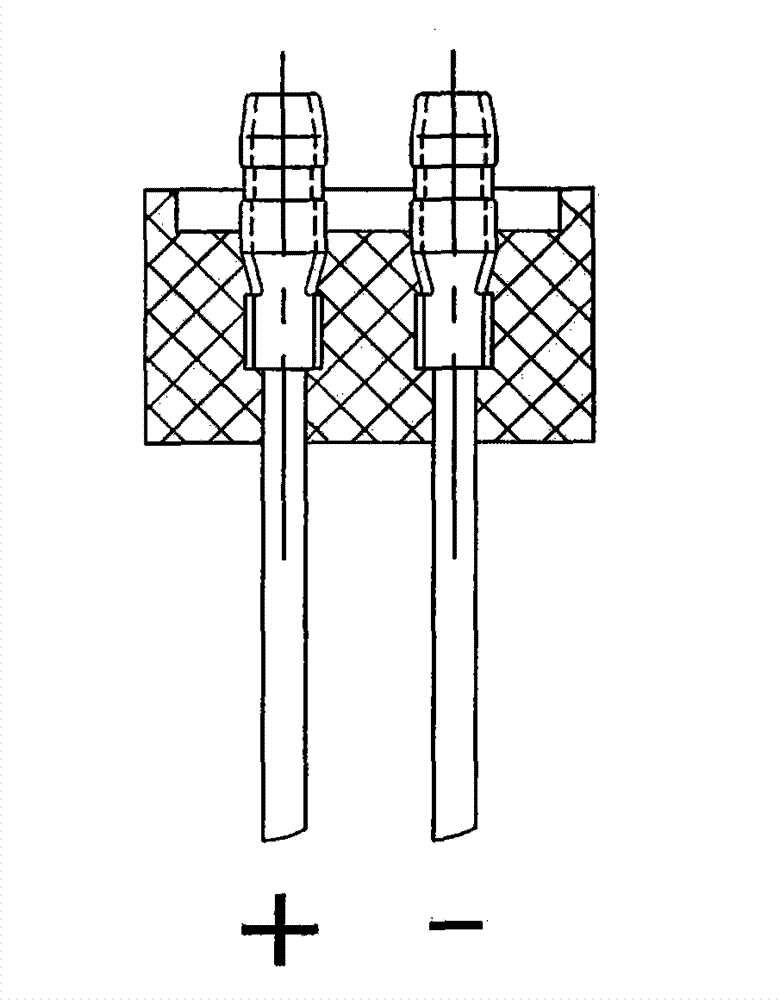

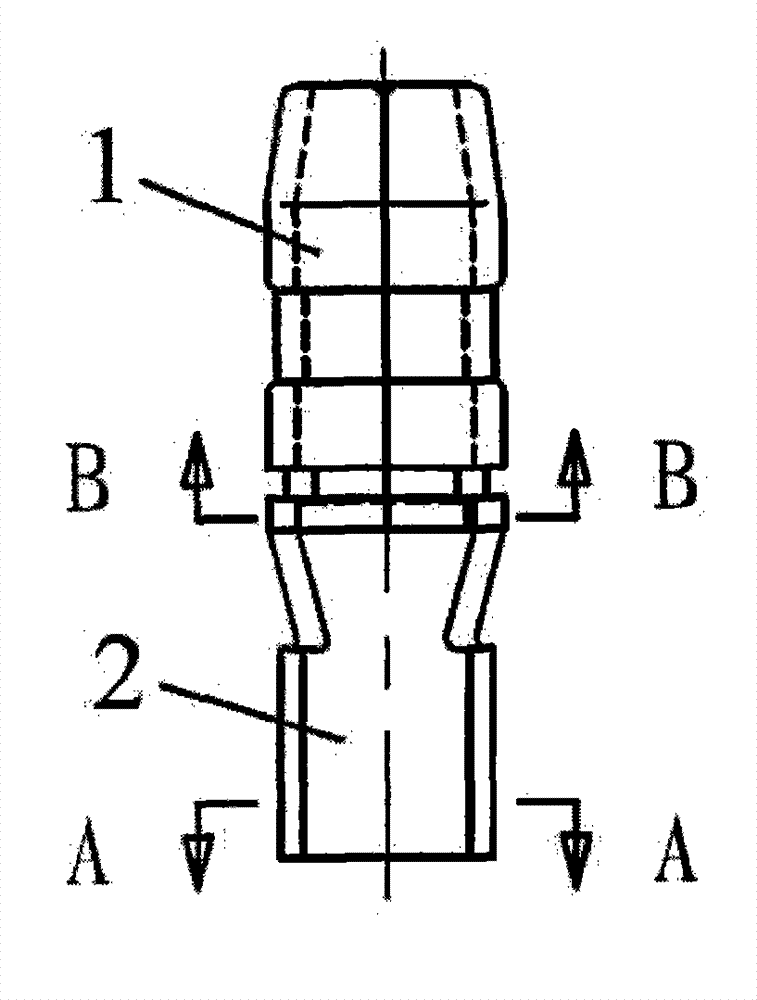

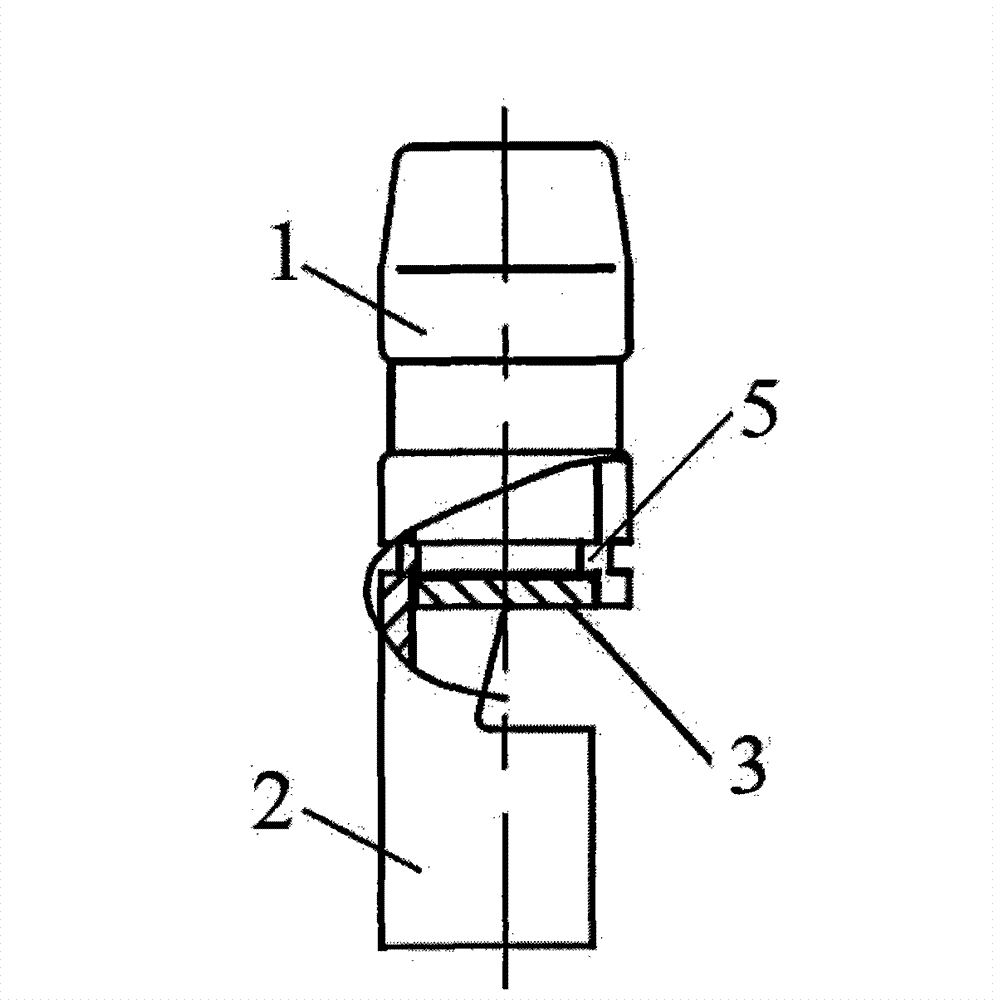

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, it is composed of a plug 1 and a wire crimping end 2. The plug part 1 is in the shape of a cylinder with a closed side wall, and the wire crimping end 2 is a curved surface structure that retains part of the side wall. The crimping terminal is packaged by an injection molding machine, wherein, A circular plate cover 3 is arranged at the lower end of the plug part. The circular plate cover 3 is formed by punching, and is connected with the side wall of the lower end of the plug through a small connecting section 4. A step 5 is provided in the inner hole of the lower end of the plug, and the step is the smallest. The diameter of the inner hole is smaller than the diameter of the disc cover, and the disc cover 3 and the stepped hole are tightly fitted.

[0018] In practice, the cylindrical structure of the plug part may also be a square cylinder with a square hole. At this time, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com