C-axis tilt gallium nitride FBAR piezoelectric mass sensor

A quality sensor, gallium nitride piezoelectric technology, applied in the field of quality sensors, can solve the problems of large volume, high quality sensitivity, miniaturization, integration, large sound wave attenuation, etc., and achieve the effect of high quality sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

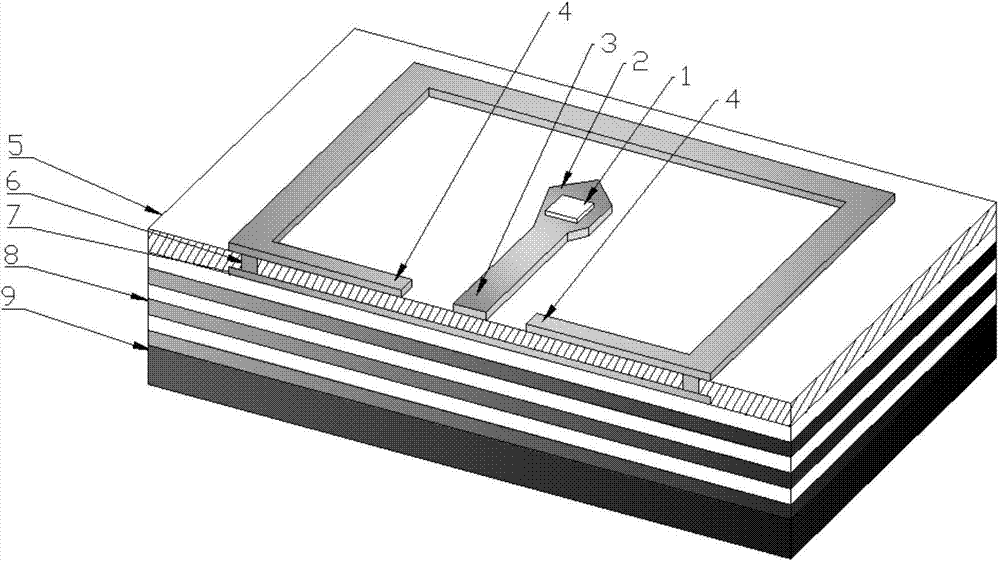

[0024] combine figure 1 As shown, a c-axis tilted gallium nitride FBAR piezoelectric mass sensor includes a sensitive layer 1, an upper electrode 2, a signal terminal 3, a ground terminal 4, a piezoelectric film 5, an etching hole 6, a lower electrode 7, and a Bragg reflection layer 8 and substrate 9 .

[0025] In this specific embodiment, the gallium nitride substrate 9, on the one hand, is used as a supporting layer of the sensor, and on the other hand, as a semiconductor, the peripheral circuit can be etched to integrate with the piezoelectric mass sensor, and on the upper surface of the gallium nitride substrate 9 Depositing the Bragg reflection layer 8; the Bragg reflection layer 8 is formed by alternately laminating three layers of high acoustic resistance layers and three layers of low acoustic resistance layers. A lower electrode 7 is deposited on the upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com