Novel high static and low dynamic rigidity piecewise linear vibration isolator and work method thereof

A piecewise linear, low dynamic stiffness technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve the problems of poor static equilibrium position stability, poor vibration isolation effect, poor stability, etc., to achieve Increase the vibration isolation frequency band, improve the low frequency vibration isolation effect, and reduce the resonance frequency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

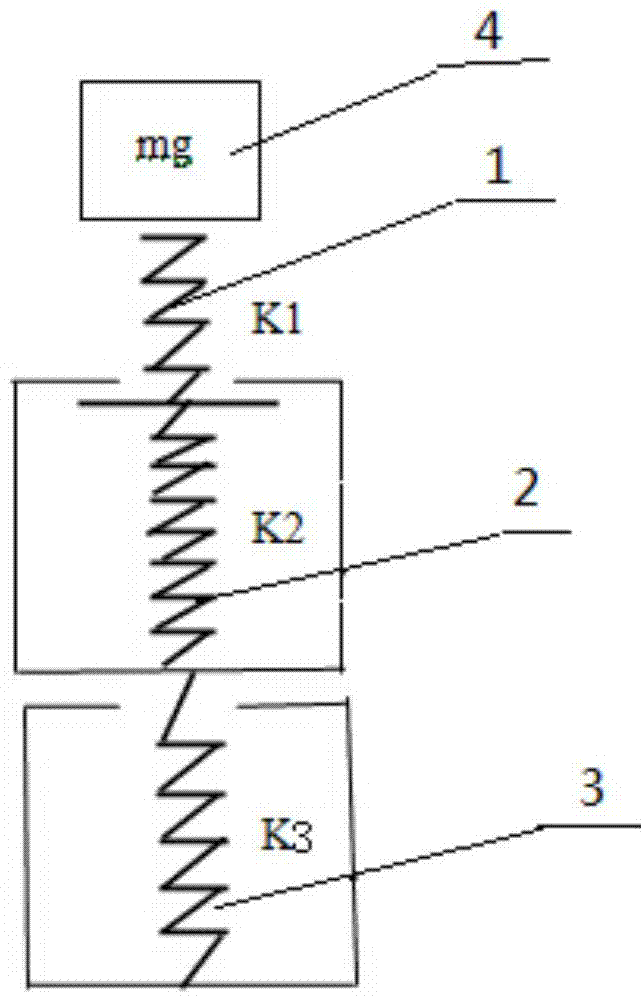

[0033] like figure 2 As shown, a new type of segmental linear vibration isolator with high static and low dynamic stiffness, including spring 1 in the upper section, spring 2 in the middle section and spring 3 in the lower section, are connected in series in three sections;

[0034] The stiffness of the upper spring 1 is K 1 , when the vibration isolation object 4 is installed above the segmented linear vibration isolator, the upper spring 1 produces static compression; the stiffness of the middle spring 2 is K 2 , the middle section spring 2 is in a precompressed state, and its precompressed amount is greater than the weight of the vibration isolation object, where K 2 1 ; The stiffness of the lower spring 3 is K 3 , K 3 The value can be set with K 2 Equal, the lower spring 3 is in a pre-stretched state, and its pre-stretch amount is also greater than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com