A type of round lip impregnated diamond bit automatic rock removal device

A technology of diamond-impregnated and diamond drill bits, which is applied in the field of automatic rock removal devices for round-lip diamond-impregnated drill bits. It can solve the problems of affecting drilling quality, easy removal of rock powder, and poor adaptability of drill bits. Effect of reducing drilling accidents and good working characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

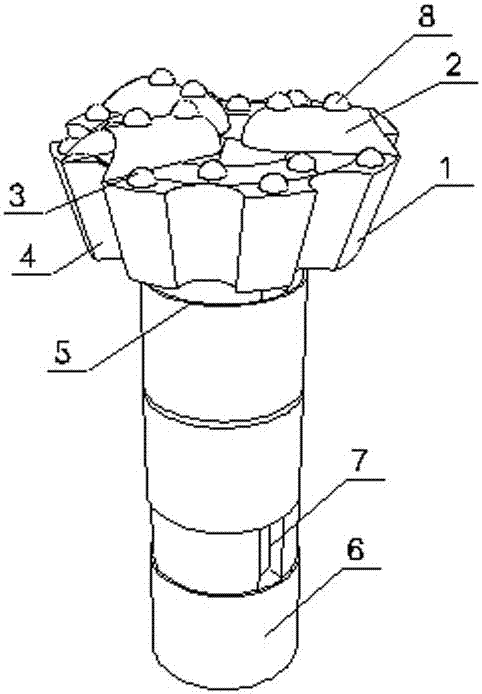

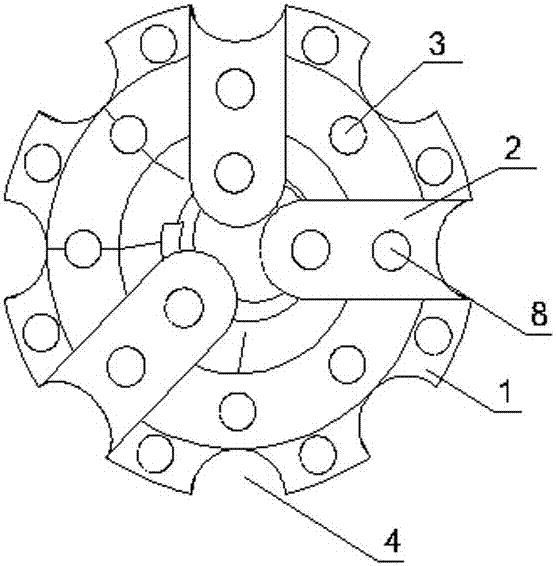

[0028] A type of round-lip impregnated diamond drill bit automatic rock removal device, comprising a hollow diamond drill bit 1 and a hollow drill rod 6 connected by a connecting ring 5, the inner diameter of the hollow diamond drill bit 1 is equal to the inner diameter of the hollow drill rod 6, That is, the two ports are opposite and then connected into one body through a connecting ring. The upper surface of the hollow diamond drill 1 is provided with three blades 2 and the first diamond layer 3, and the surface of the blade 2 is provided with a second diamond layer 8. The hollow At least one chip removal guide groove 4 is arranged around the diamond drill bit 1, and the three blades 2 are arranged in a font shape. The axis of the chip removal guide groove 4 is inclined to the hollow diamond drill bit 1. There is at least one chip removal slot 7 .

[0029] Put the product type round lip impregnated diamond drill bit of the present invention into the device for automatically...

Embodiment 2

[0031] A type of round lip impregnated diamond drill bit automatic rock removal device, comprising a hollow diamond drill bit 1 and a hollow drill rod 6 connected by a connecting ring 5, the inner diameter of the hollow diamond drill bit 1 is smaller than the inner diameter of the hollow drill rod 7, The hollow diamond bit 1 is about to be inserted in the hollow drill rod 7, and then fixedly connected into one body with the connecting ring 5. The upper surface of the hollow diamond bit 1 is provided with three blades 2 and the first diamond layer 3, and the surface of the blade 2 is provided with There is a second diamond layer 8, four chip guide grooves 4 are arranged around the hollow diamond bit 1, arranged symmetrically in pairs, the three blades 2 are arranged in a font shape, and the thickness of the blade is 0.5-1.0mm. It is 20-30° chamfering, and the smoothness is 4-7 grades. The axis of the chip removal guide groove 4 is inclined 5-15° inwardly to the hollow diamond dr...

Embodiment 3

[0033] A type of round lip impregnated diamond drill bit automatic rock removal device, comprising a hollow diamond drill bit 1 and a hollow drill rod 6 connected by a connecting ring 5, the inner diameter of the hollow diamond drill bit 1 is smaller than the inner diameter of the hollow drill rod 6 by 0.2 cm, the upper surface of the hollow diamond drill bit 1 is provided with three blades 2 and the first diamond layer 3, the surface of the blade 2 is provided with the second diamond layer 8, and the diamond particle diameter of the first diamond layer 3 is larger than the second The diamond layer 8 is small, and the hollow diamond bit 1 is provided with four chip removal guide grooves 4, which are symmetrically arranged in pairs, and the three blades 2 are arranged in the shape of a finished product, and the thickness of the blade 2 is 0.8mm, and the cutting edge is 20° Chamfering, smoothness grade 7, the axis of the chip removal guide groove 4 is inclined 10° inwardly to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com