Betel Nut Distributing and Counting Device

The technology of a counting device and a material distributing device is applied in the directions of packaging, packaging protection, transportation and packaging, which can solve the problems of consuming a lot of manpower and time, not being very efficient, affecting the quality of product production, etc. The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

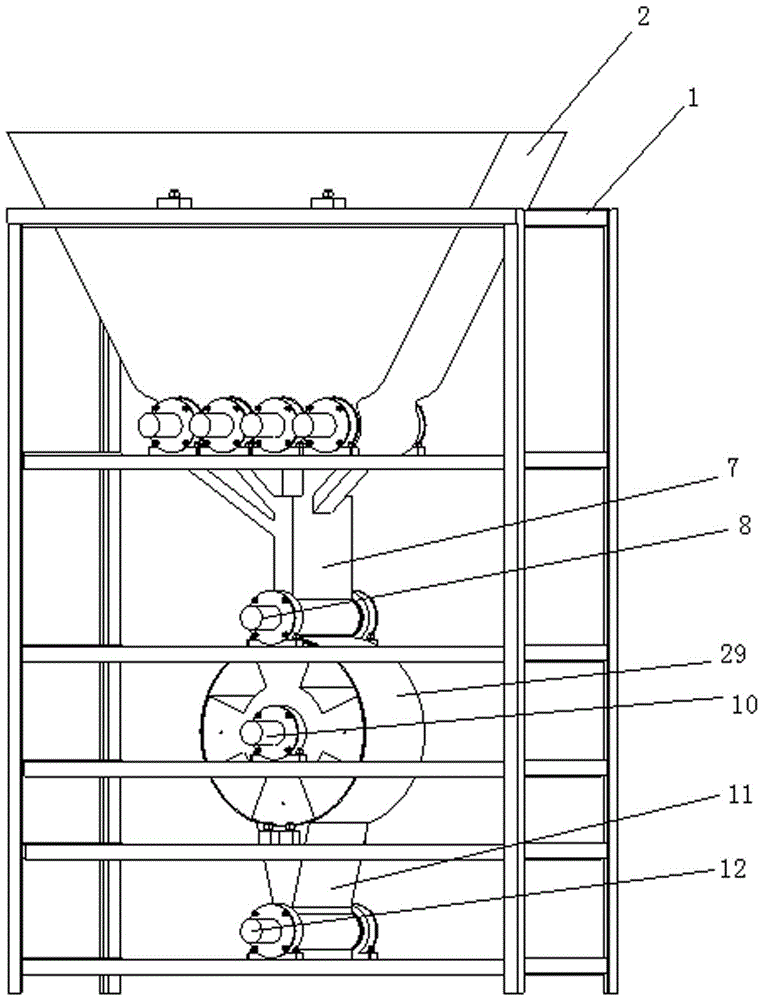

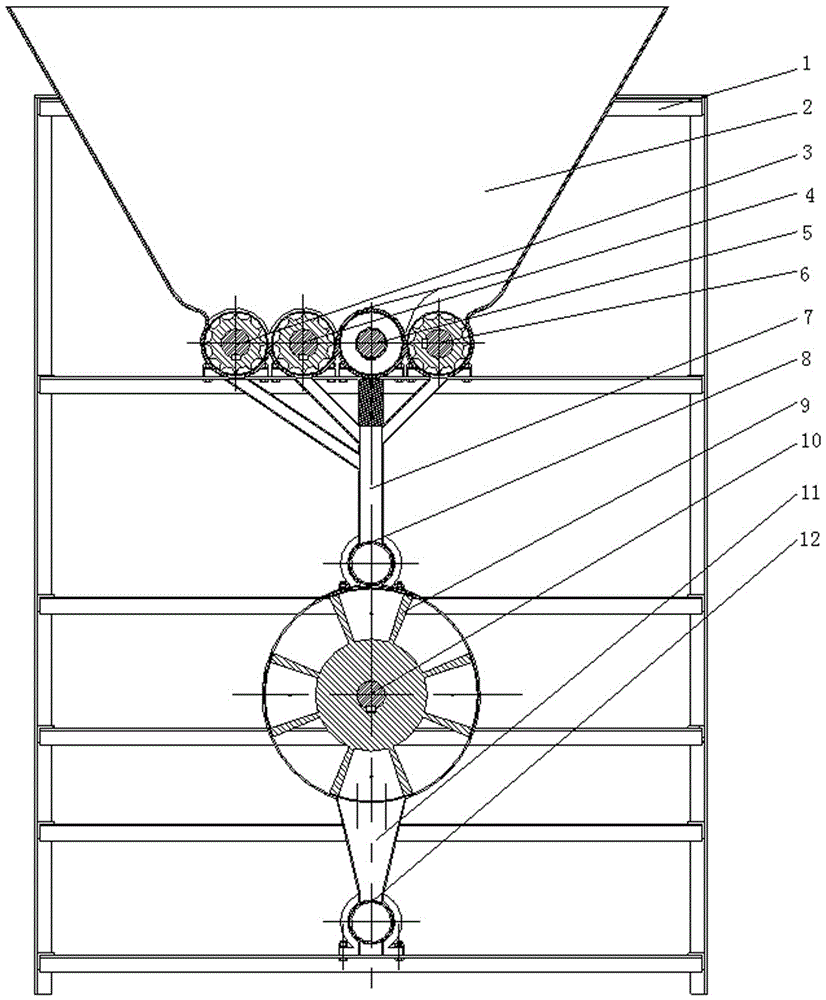

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention includes a frame 1, a material hopper 2, a blanking channel 7, and a hopper 11. The material hopper 2 is fixed on the frame 1 by bolts I16, nuts I17 and gaskets I18, and the bottom of the material hopper 2 is provided with There are 4 outlets, and a distribution device is provided above each outlet.

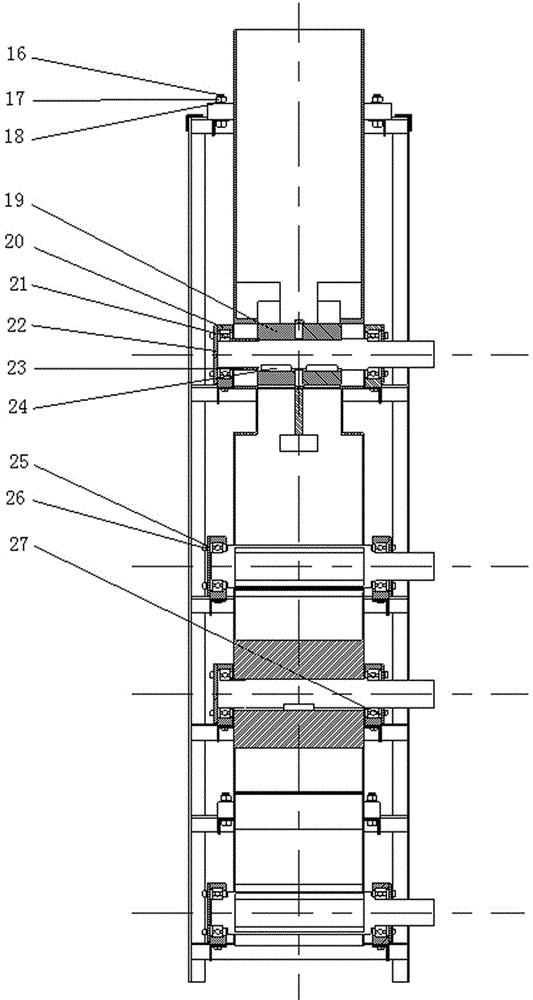

[0026] Such as Figure 5 As shown, the distributing devices all include a distributing shaft, a distributing wheel 19 and a stepping motor. From left to right, the 4 distributing devices respectively include distributing shaft I3, distributing shaft II4, distributing shaft III5, Ⅳ6, material distribution shaft Ⅰ3, material distribution shaft Ⅱ4, material distribution shaft Ⅲ5, material distribution shaft Ⅳ6 are respectively connected with the stepping motor driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com