Ampoule printing device

A technology for printing characters and ampoules, which is applied in the field of glass bottle body printing machines, can solve problems such as broken bottles, and achieve the effect of reducing processes, reducing the number of inspections, and making movements soft and smooth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

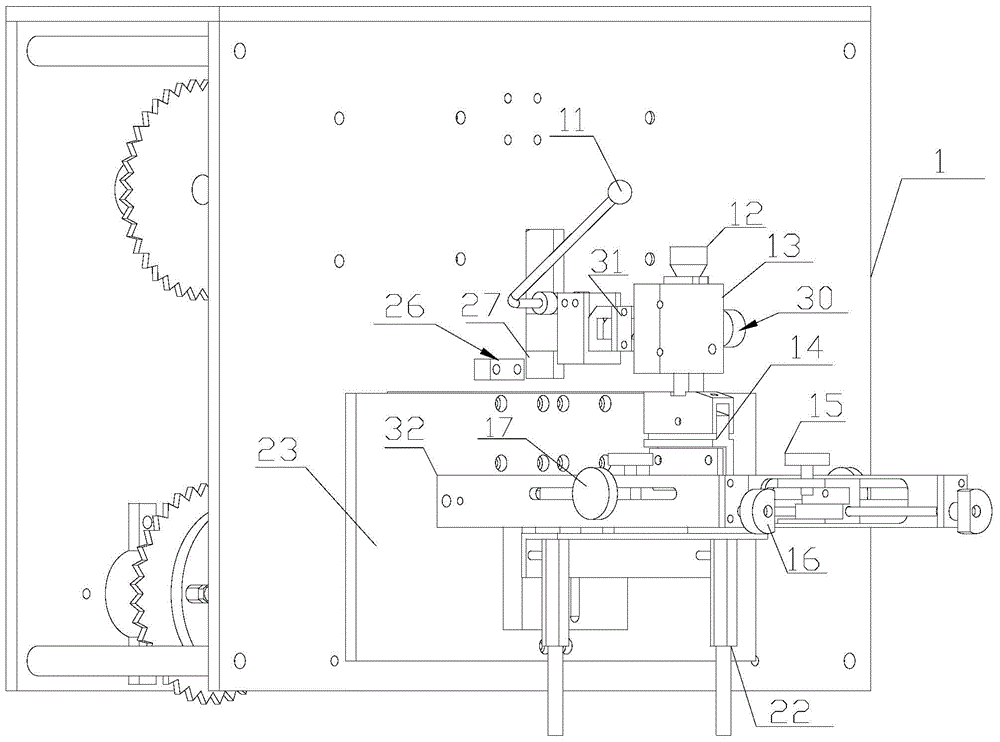

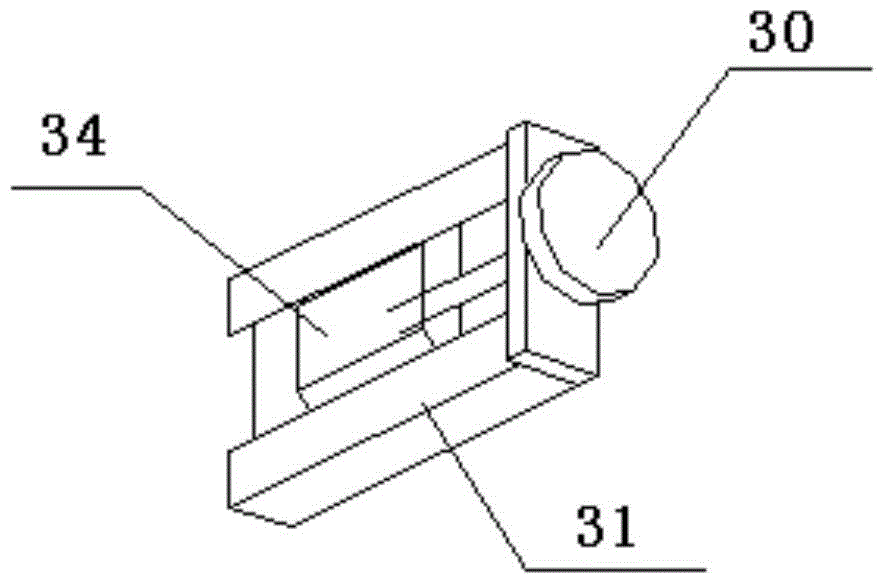

[0023] Such as figure 1 , 2 As shown in 4, the ampoule printing device provided by the present invention includes a box body 1, a horizontal support rod 9, and a scraper up and down drive device and a printing screen reciprocating drive device installed in the box body 1. The scraper up and down adjustment block 13 is installed at one end of the horizontal support rod 9, and the other end of the horizontal support rod 9 extends into the box 1 and is connected with the scraper up and down driving device. The scraper 14 is installed at the lower end of the upper and lower adjustment block 13 of the scraper, and the scraper 14 can be made of rubber. The scraper up-and-down driving device drives the scraper up and down adjustment block to jump up and down, thereby driving the scraper 14 to jump up and down. The screen mounting plate 19 is horizontally arranged below the scraper 13, a through groove is opened on the screen mounting plate 19, and a printing screen (not shown in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com