Tobacco bundle head loosening machine

A technology of dispersing machine and cigarette handle, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of labor and time-consuming, inability to remove defective cigarettes and non-smoke inclusions, and low work efficiency.

Inactive Publication Date: 2013-04-03

云南同云科贸有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As far as the handle is concerned, at present, there are mainly two methods of manual release and mechanical release at home and abroad. Manual release is labor-intensive and time-consuming, and the work efficiency is extremely low, which is no longer the requirement of industrialized continuous production.

Although the mechanical release solves the problems of high labor intensity and low work efficiency in manual release, it cannot remove the defective cigarettes and non-smoke inclusions bundled in the cigarette holder

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0014] Example 2

Embodiment 2

[0016] Example 3

Embodiment 3

[0018] Example 4

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

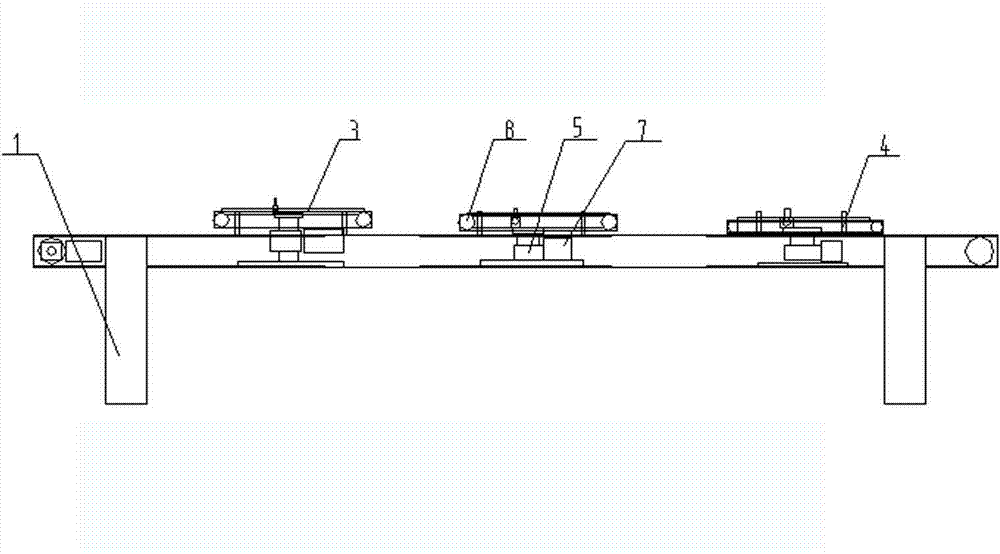

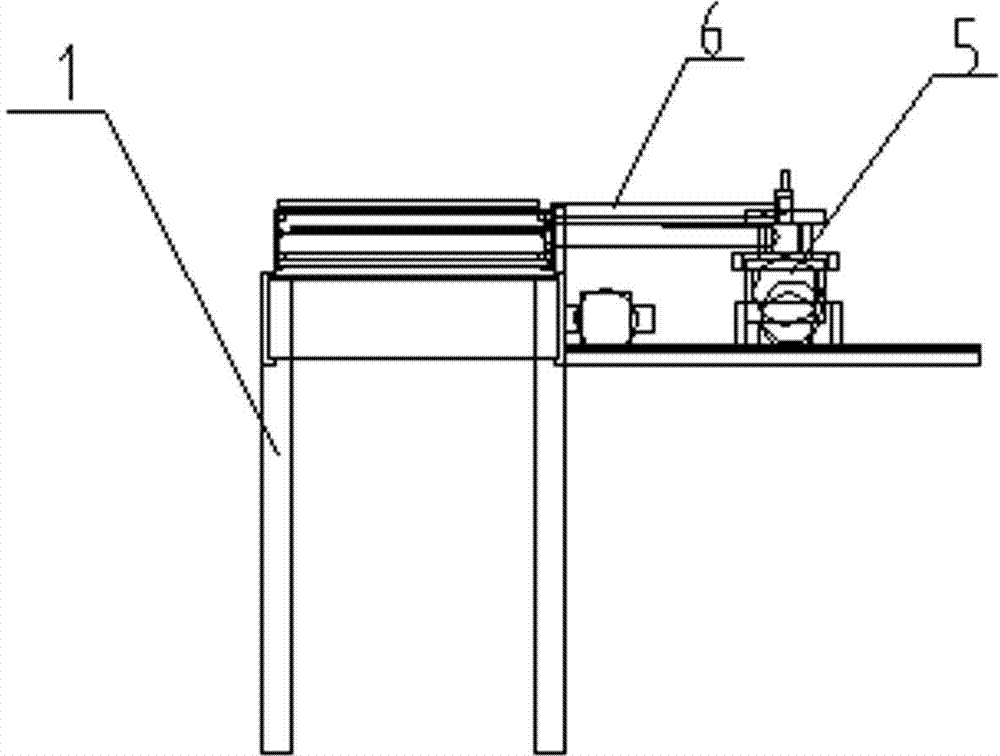

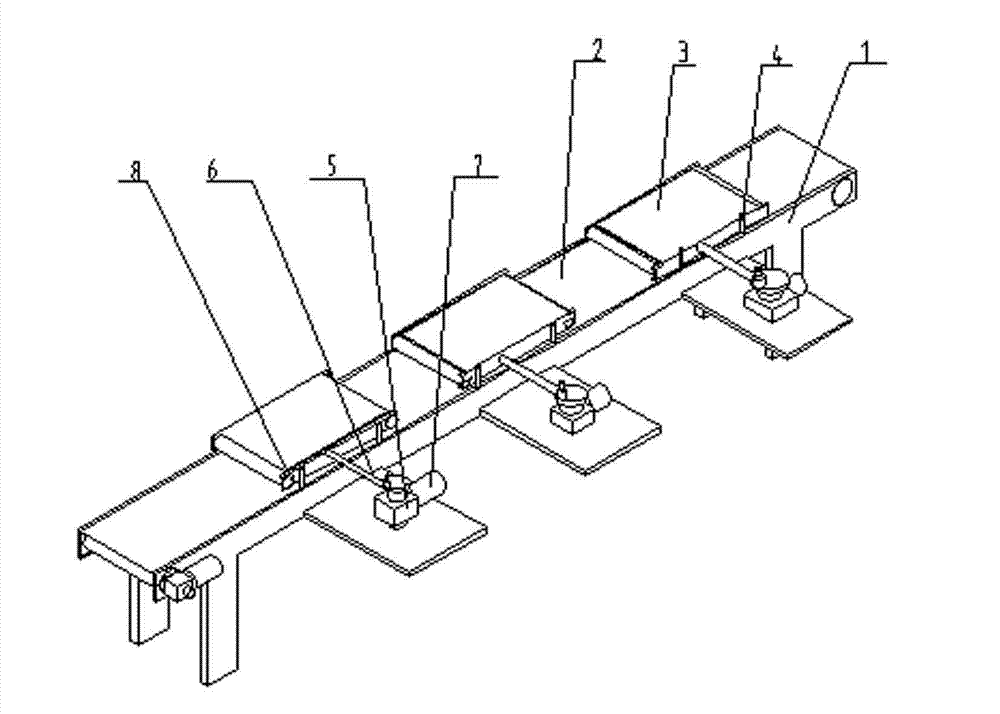

The invention provides a tobacco bundle head loosening machine, relates to tobacco processing equipment, and particularly to equipment for loosening a tobacco bound head. The machine comprises a frame, a conveying belt and a millstone conveying belt, wherein the conveying belt is arranged on the frame; the millstone conveying belt is fixed above the conveying belt through a spring and connected with an eccentric wheel which is fixed on the frame; the conveying belt and the eccentric wheel are respectively connected with a speed reducing motor which is fixed on the frame; and the millstone conveying belt is connected with an electronic roll. The tobacco bundle head loosening machine has the advantages of novel and unique structure and high working efficiency and is simple for operation.

Description

technical field [0001] The invention relates to tobacco processing equipment, in particular to a device for kneading the ends of tobacco handles. Background technique [0002] Tobacco leaf unbundling is an important link before threshing and redrying. After untying and spreading the bundled tobacco leaves, they can be heated and humidified, so as to meet the requirements of the threshing process and reduce the damage of tobacco leaves. Rate. As far as untying is concerned, at present, there are mainly two methods of manual untying and mechanical untying at home and abroad. Manual untying is labor-intensive and time-consuming, and the work efficiency is extremely low, which is no longer the requirement of industrialized continuous production. Although the mechanical release solves the problems of high labor intensity and low work efficiency in the manual release, it cannot remove the defective cigarettes and non-smoke inclusions bundled in the cigarette holder. Although the...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): A24B3/06

Inventor 周大同

Owner 云南同云科贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com