Thermoforming device

A technology of thermoforming and pressing plates, which is applied in the direction of presses, manufacturing tools, etc., to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

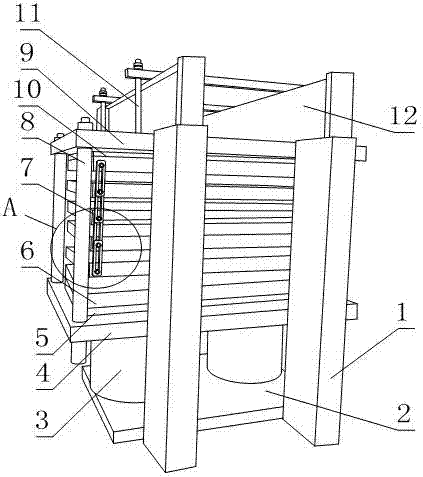

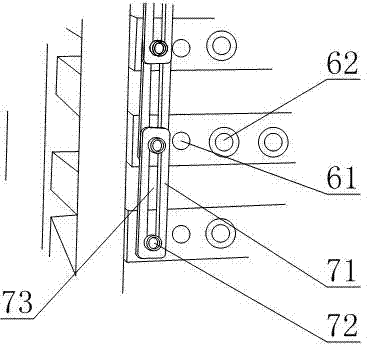

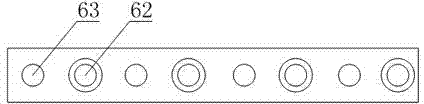

[0032] like figure 1 and figure 2 As shown, a thermoforming device includes a frame and a press plate 6 arranged on the frame, the press plate 6 is a plate-shaped structure with a built-in electric heating block 62, and the frame includes a stand 1 and a stand set on the stand The base plate 2 and the top plate 9 on the frame 1, the pressure plate 6 is located between the base plate 2 and the top plate 9, and the pressure plate 6 is a plurality of pieces, and the bottom plate 2 is also fixed with a jack 3 for adjusting the gap between the pressure plates 6 or the size of the compressive stress , connecting buckles 7 for limiting the maximum distance between adjacent pressing plates 6 are also provided between adjacent pressing plates 6;

[0033] The connecting buckle 7 comprises a strip-shaped buckle plate 71, a strip-shaped hole 73 is arranged on the length direction of the buckle plate 71, and two connecting bolts 72 are arranged in the strip-shaped hole 73, and the two co...

Embodiment 2

[0039] The present embodiment is further limited on the basis of embodiment 1, as figure 1 and figure 2 As shown, in order to ensure the uniformity of the stress on each point of the carbon crystal heating film during the pre-pressing process, it also includes a pressure equalizing plate 64 and a plurality of shape-keeping rods 8 parallel to each other, and the shape-keeping rods 8 are all fixed on the top plate 9 , the said pressure equalizing plate 64 is provided with through holes equal in number to the number of shape maintaining rods 8, said through holes are clearance fit with one shape maintaining rod 8 respectively, and the pressing plate 6 at the lowermost end is fixed on the top of the pressure equalizing plate 64 On the surface, the jack 3 acts on the lower surface of the pressure equalizing plate 64, and the shape maintaining rod 8 and the piston rod of the jack 3 are parallel to each other. In the above structure, the shape retaining rod 8 defines the angle betw...

Embodiment 3

[0043] This embodiment is further limited on the basis of any one of the above embodiments, such as figure 1 and figure 2 As shown, in order to facilitate the uniformity of the temperature values at each point of each pressing plate 6, the pressing plates 6 are all copper plates, so that the carbon crystal heating film is separated from the pressing plate 6 after pre-pressing or the pressing plate 6 and the carbon crystal heating film are lowered quickly. temperature, each platen 6 is provided with a cooling medium channel 61 . The provided cooling medium channel 61 is used for passing cold fluid to take away the heat in the platen 6 .

[0044] In order to facilitate heat transfer from the electric heating block 62 to the pressing plate 6 , fins are provided on the outer side of the metal sleeve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com