Method for eliminating ITO blank interlayer during pressure slip casting

A technology for grouting molding and eliminating pressure, applied in ceramic molding machines, die-casting molds, etc., can solve the problems of cracking of ITO blanks and unqualified products, preventing dehydration difficulties, preventing interlayer phenomenon, and reducing residual water. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

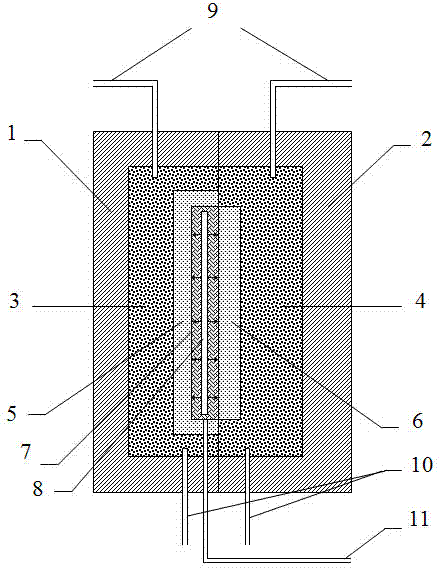

Image

Examples

Embodiment 1

[0040] Take 1432g of deionized water according to the solid content of 88% of the ITO powder, then select 94.5g of polyacrylic acid dispersant according to 0.9% of the total weight of the ITO powder, and select 31.5g of ammonia water with a concentration of 28% according to 0.3% of the total weight of the ITO powder. g, select 52.5g of polyacrylamide filter aid according to 5‰ of the total weight of ITO powder. Put polyacrylic acid dispersant, ammonia water and polyacrylamide filter aid into deionized water and stir evenly to obtain a mixed solution. Pour the mixed solution into the stainless steel tank, add each part of the ITO powder in three batches at a speed of 80r / min for stirring, and control the time of each batch of stirring and grinding at 15h, and the total time of three batches of stirring and grinding It is controlled at 45h, and the mass ratio of zirconia balls to the total weight of ITO powder is required to be controlled at 4:1, and the primary ITO slurry is ob...

Embodiment 2

[0045] Take 1167g of deionized water according to the solid content of 90% of the ITO powder, then select 162.75g of polycarboxylic acid dispersant according to 1.55% of the total weight of the ITO powder, and select 28% ammonia water according to 0.5% of the total weight of the ITO powder 52.5g, select polyacrylamide filter aid 210g according to 20‰ of the total weight of ITO powder. Put polycarboxylic acid dispersant, ammonia water and polyacrylamide filter aid into deionized water and stir evenly to obtain a mixed solution. Pour the mixed solution into the stainless steel tank, add each part of the ITO powder in three batches at a speed of 120r / min for stirring, and control the time of each batch of stirring and grinding at 10h, and the total time of three batches of stirring and grinding It is controlled at 30h, and the mass ratio of zirconia balls to the total weight of ITO powder is required to be controlled at 2:1, and the primary ITO slurry is obtained after stirring a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com