Magnetism isolating structure of assembling manipulator of automatic magnet assembling machine

A technology of manipulators and assembly machines, applied in manipulators, metal processing, metal processing equipment, etc., can solve the problems of easy deformation and wear of plastics, low precision, and inconvenient pick-and-place manipulation, and achieve good wear resistance and iron. The effect of low element content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the description of the drawings and specific embodiments, and similar reference numerals in the drawings represent similar components.

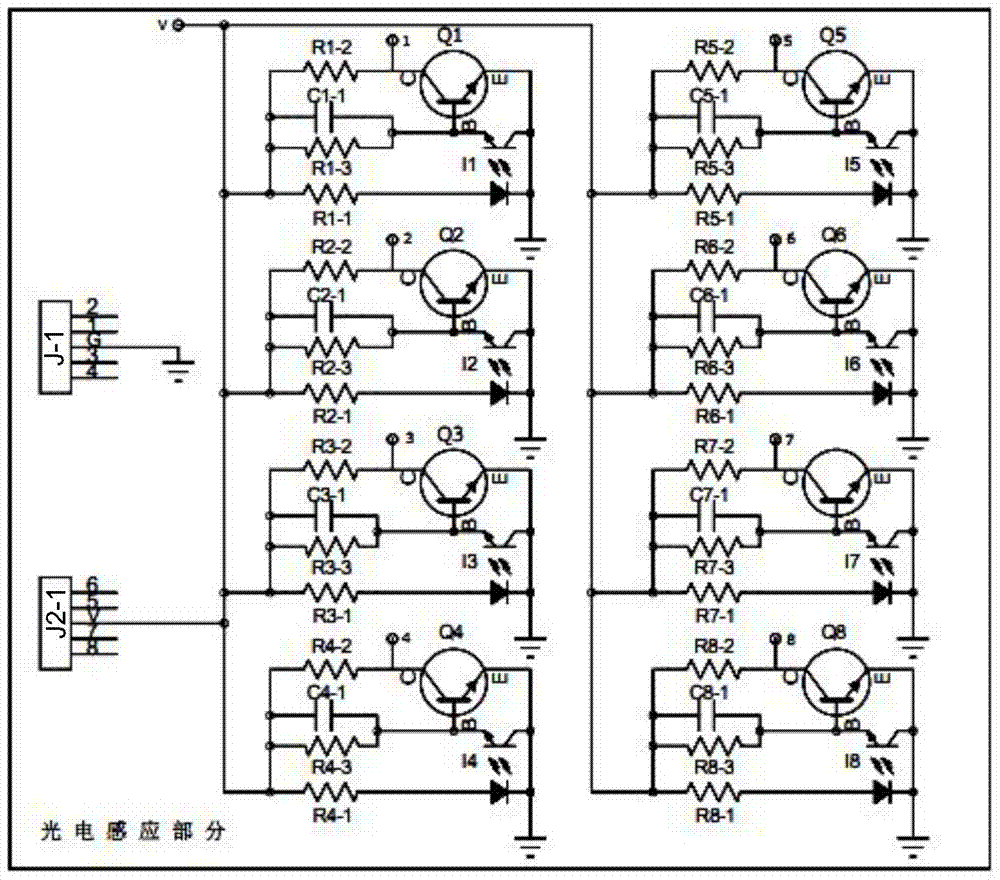

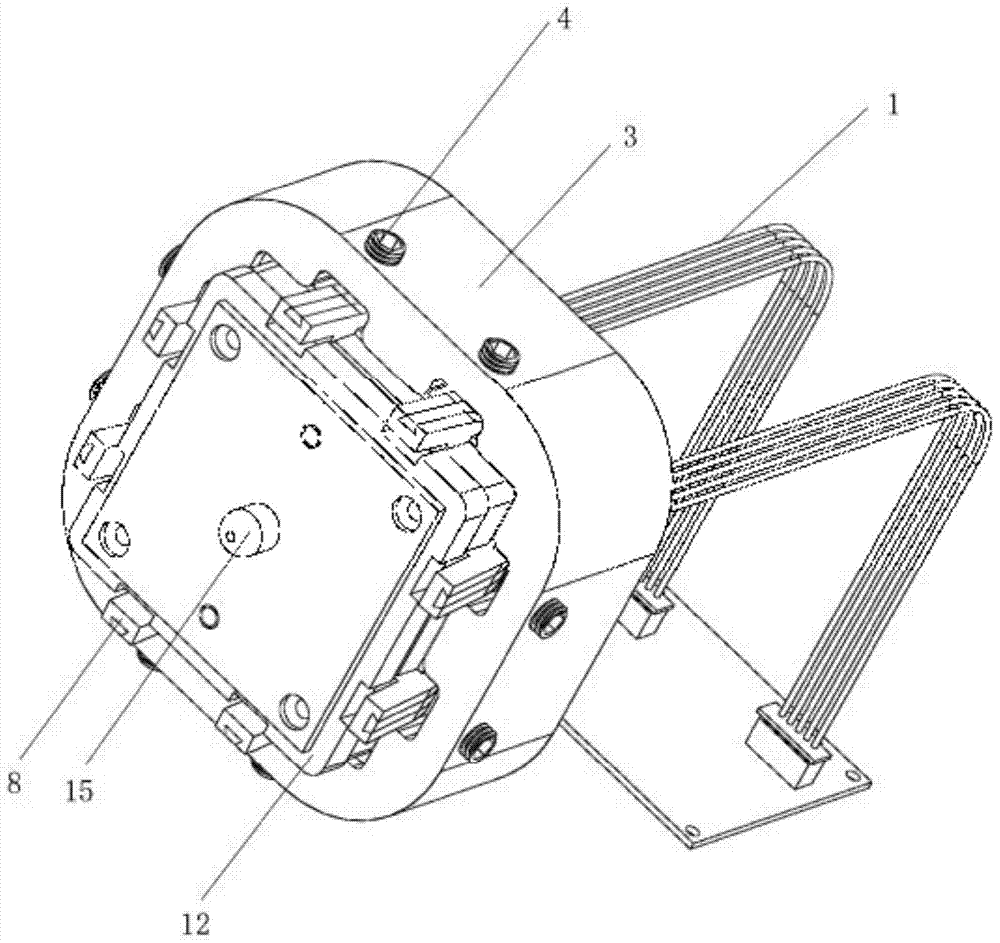

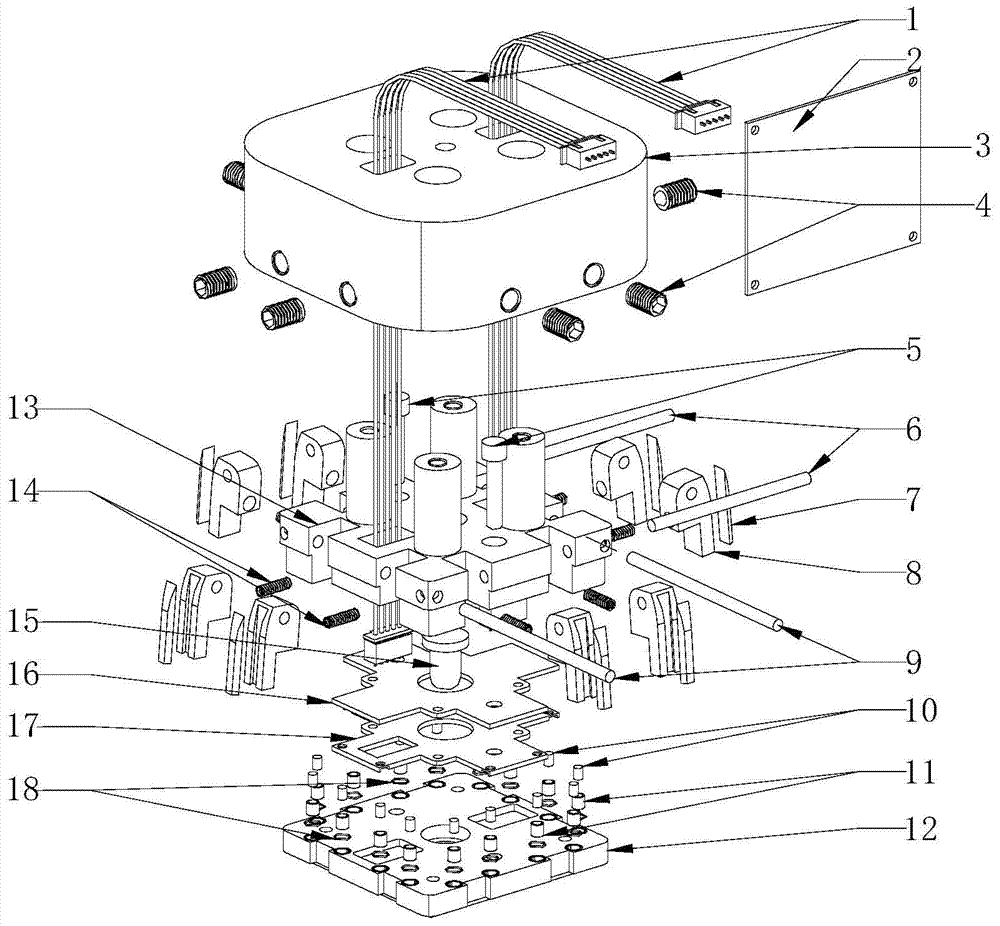

[0014] Such as Figure 1-3 As shown, a magnetic isolation structure of an assembly manipulator of a magnet automatic assembly machine, the assembly manipulator is installed on the upper end of the magnet automatic assembly machine, and the assembly manipulator includes a control board 16, a gripper limit block 3, a positioning pin 5, and a gripper fixing seat 13 , gripper 8, gripper hinge pin 6 cylinder 19 and magnet limit block 12, control board 2 connects control system by connection line 1, gripper fixed seat 13 upper end is provided with mounting column 20, and mounting column 20 and cylinder 19 lower end surfaces Fixedly connected, the cylinder 19 pistons are connected to the gripper stopper 3, and drive the gripper stopper 3 to move up and down. A pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com