Conveying process for liquid crystal glass primary materials

A technology of liquid crystal glass and raw materials, which is applied in the field of liquid crystal glass production, can solve the problems that the uniformity cannot meet the production process requirements of liquid crystal glass, production process fluctuations, batch material composition fluctuations, etc., to prevent secondary delamination and segregation, and ensure Moisture requirements, good uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

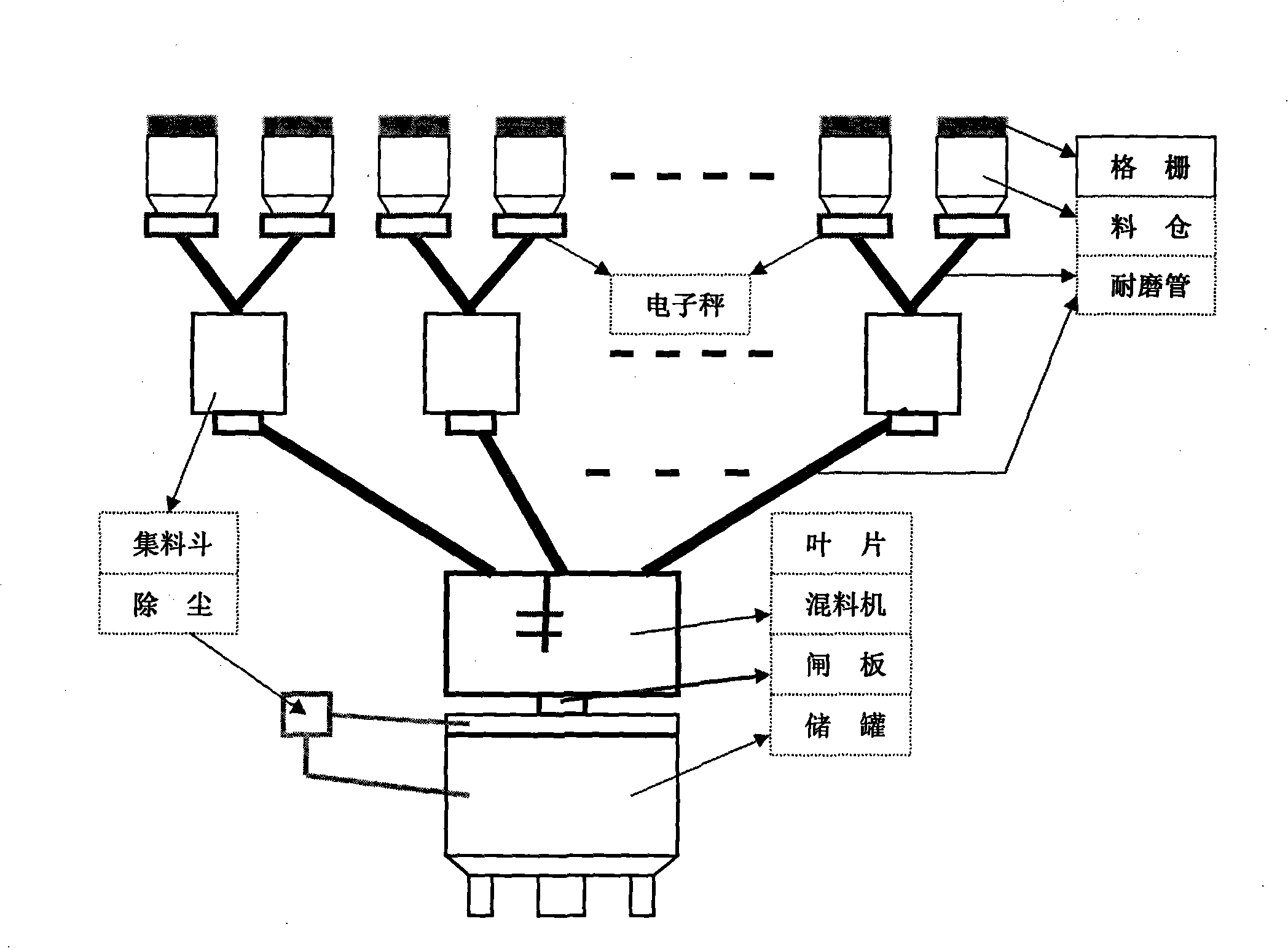

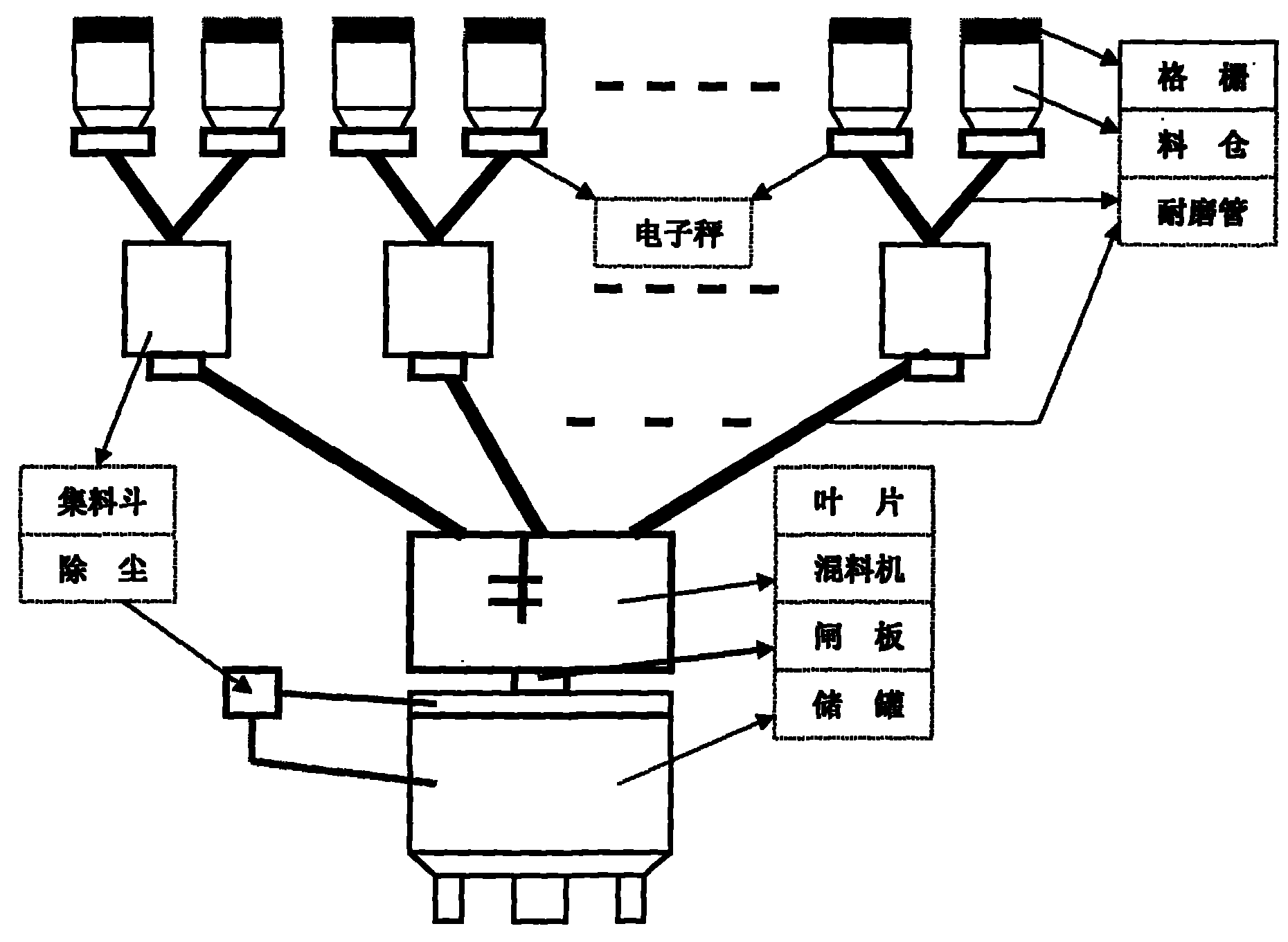

[0035] Control is carried out at the beginning of raw material input, and a set of steel grid device is installed at the feeding port to remove iron from the batch material, so as to remove the iron content in the raw material and ensure the quality of the raw material.

[0036] The weighed raw materials are discharged into the collecting hopper through the gate under the electronic scale, and the wear-resistant pipeline is used to connect the gate and the collecting hopper, and then the collecting hopper is connected to the mixer, and a vibration device is installed at the lower part of the collecting hopper. The electronic scale adopts a high-precision electronic scale, and the electronic scale is designed with protective measures such as a windshield and a uniform tube, so that the weighing accuracy of the electronic scale can meet the requirements of 1 / 4000. Then it is discharged into the collecting hopper through the gate. The wear-resistant pipe and the horizontal plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com