Method and equipment for welding steel pipe and fins of H-type coal economizer used for boiler

A welding method and welding equipment technology, applied in the field of boiler manufacturing, can solve the problems of slow welding speed, reduced heat exchange efficiency, low production efficiency, etc., and achieve the effects of low processing accuracy requirements, improved heat exchange efficiency, and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

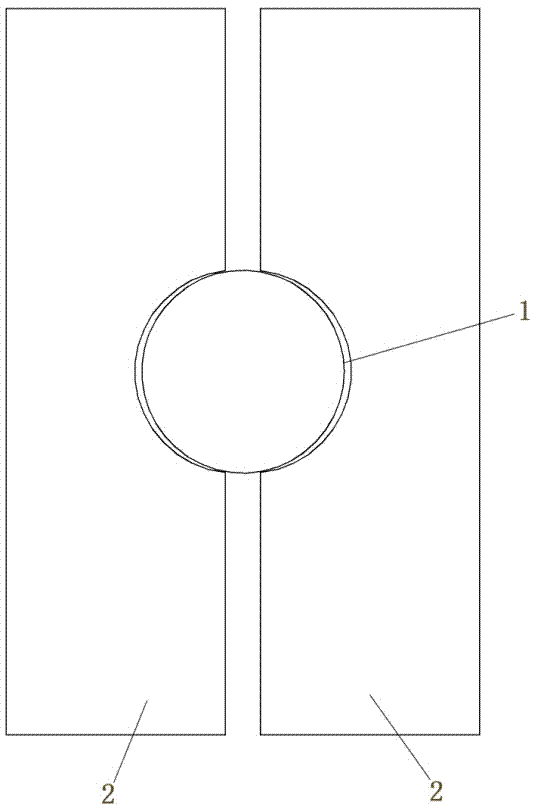

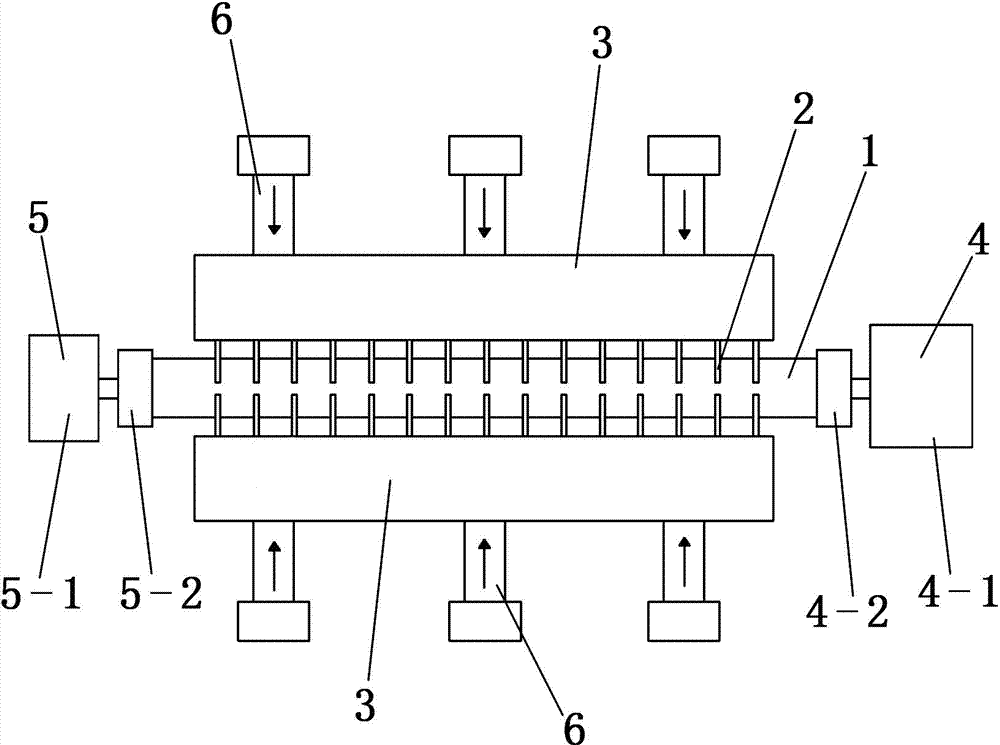

[0032] Embodiment 1: According to the manufacturing needs of an H-type economizer including a steel pipe 1, the motor drive system 4 includes a motor 4-1, an output shaft of a motor 4-1 and a three-jaw self-centering The chuck A4-2 is fixedly connected; the supporting device 5 includes a support 5-1 and a three-jaw self-centering chuck B5-2.

Embodiment 2

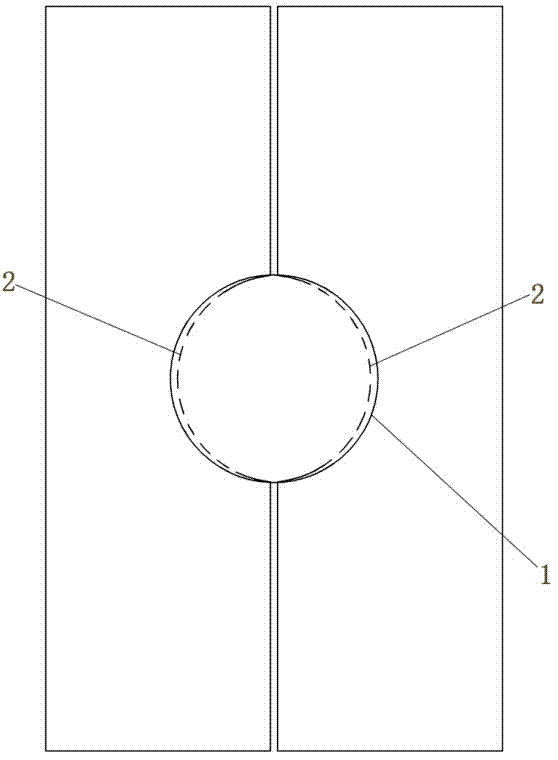

[0033] Embodiment 2: According to the manufacturing requirements of the H-type economizer including two steel pipes 1, the motor drive system 4 includes a motor 4-1, a motor 4-1 and two three-jaw self-centering chucks A4-2 connection, one of the three-jaw self-centering chucks A4-2 is fixedly connected with the output shaft of the motor 4-1, and the two three-jaw self-centering chucks A4-2 are connected through gears, so that the two three-jaw self-centering chucks The centering chuck A4-2 rotates synchronously; the support device 5 includes a support 5-1 and two three-jaw self-centering chucks B5-2, and the two three-jaw self-centering chucks B5-2 are respectively connected to the two The axis coincidence setting of a three-jaw self-centering chuck A4-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com