Large-span circular air-and-flue-gas duct system

A flue air duct, large-span technology, which is applied in the treatment of combustion products, combustion methods, exhaust gas devices, etc., can solve the problems of high civil construction investment cost and large floor space, and reduce investment costs and floor space. The effect of reducing investment costs and reducing land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

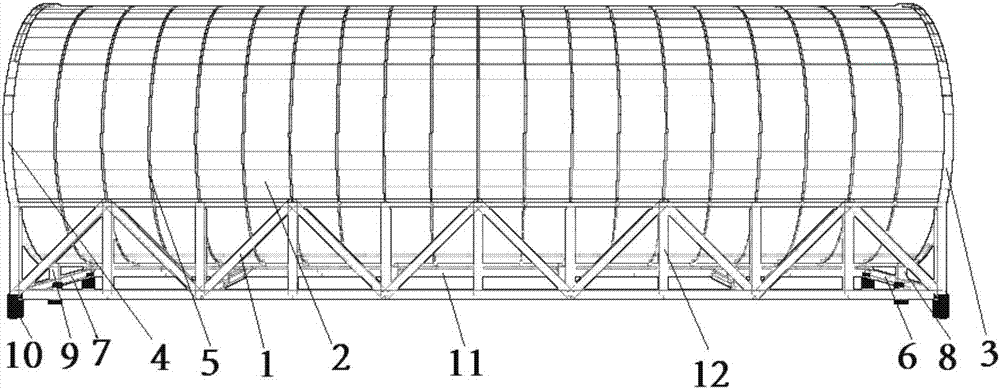

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0016] refer to figure 1 , the large-span circular flue duct system of the present invention includes a circular flue duct body 2, a bottom frame 1, a first ferrule 3, a second ferrule 4 and a number of reinforcing ribs 5, wherein the first ferrule 3 and the second ferrule 4 are respectively sleeved on the outer walls of the two ends of the circular flue duct body 2, and each reinforcing rib 5 is sleeved on the outer wall of the circular flue duct body 2. The first ferrule 3, the second The ferrule 4 and each reinforcement rib 5 are fixed on the bottom frame 1 , and the bottom of the circular flue duct body 2 is located on the bottom frame 1 , and the bottom of the bottom frame 1 is provided with a number of hangers 10 .

[0017] The bottom frame 1 includes a first truss 12 , a second truss, a first fixed rod 6 , a second fixed rod 7 , a third fixed rod 8 , a fourth ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com