Method for remotely capturing hot-rolled strip steel tracking signal

A technology for hot-rolling strip steel and tracking information, applied in metal rolling, metal rolling, length measuring devices, etc., to achieve the effects of small amount of collected data, improved retrieval efficiency, and reduced occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

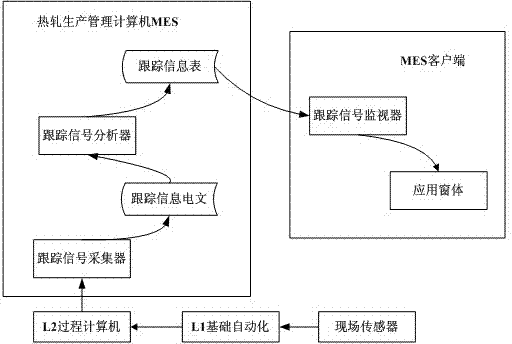

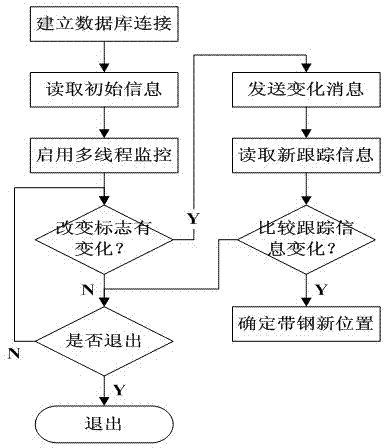

[0019] Such as figure 1 As shown, the remote capture method of the hot-rolled steel strip tracking signal provided by the present invention comprises the steps:

[0020] (1) Acquisition of strip tracking signals, on the production management computer (MES) to collect tracking information such as the strip number from the process control system (L2) and its equipment entering and leaving the rolling mill through text communication;

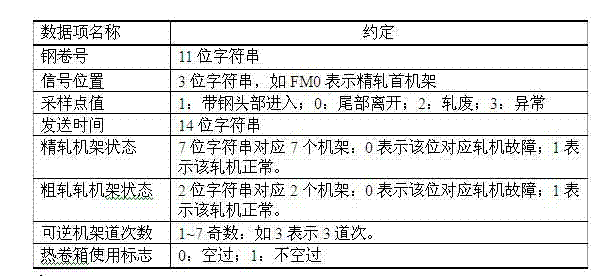

[0021] (2) Analysis of the strip tracking signal, analyzing and processing the collected tracking signal according to the strip steel number and position, and saving the effective tracking signal into the fixed-length tracking signal table of the database with the fixed tracking position as the key;

[0022] (3) Monitoring of the strip tracking signal, real-time monitoring of the tracking signal change information in the database on the production management computer (MES) client, so as to determine the position of the strip and the status of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com