Production line for automatically coating profile steel and coating method thereof

An automatic spraying and production line technology, which is applied to liquid spraying equipment, coatings, spray booths, etc., can solve the problems of difficult control of the surface coating quality of section steel, unsuitable loading and unloading and conveying methods, and easy to produce dead angles when spraying inside inside corners of section steel, etc. , to achieve the effect of solving the dead angle of spraying, improving the quality of the coating, and good cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

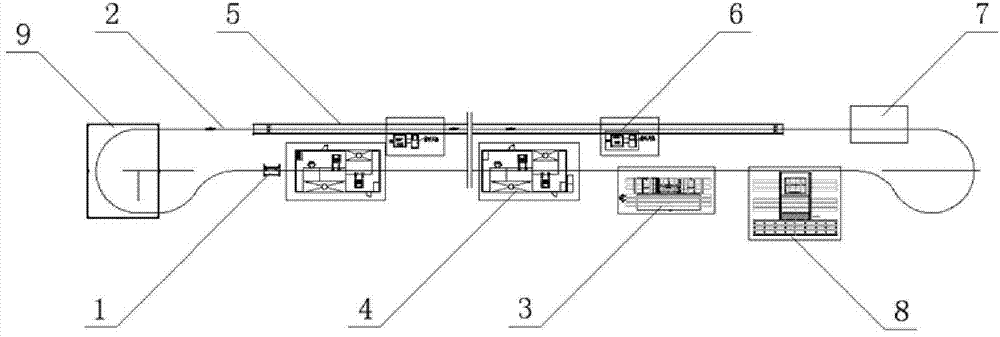

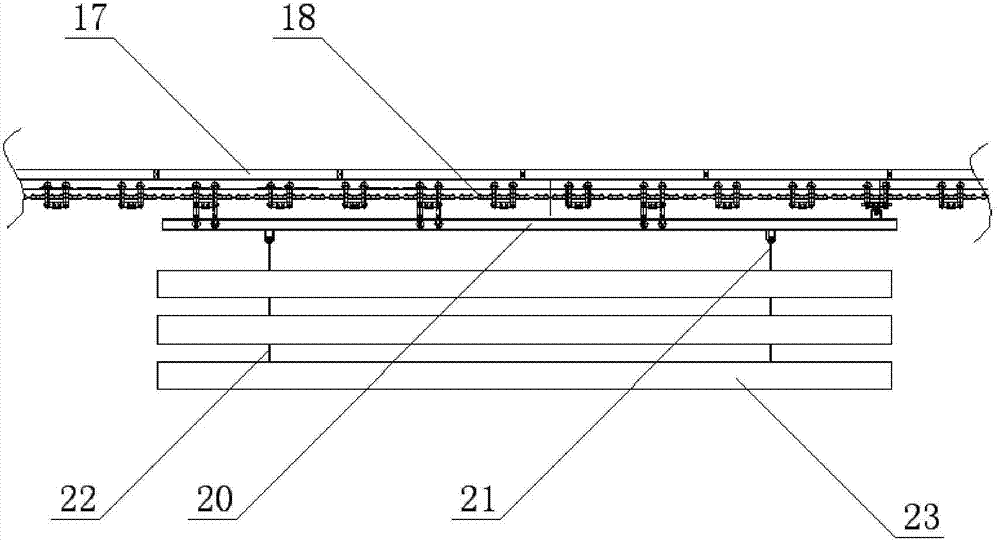

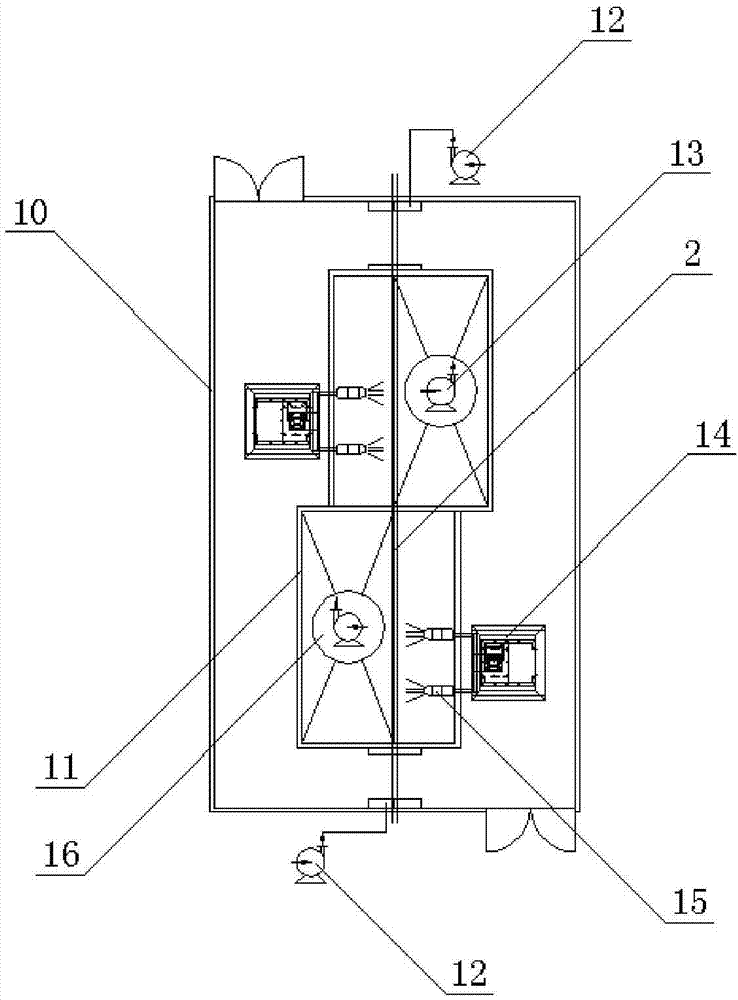

[0041] see Figure 1 to Figure 14 , a kind of section steel automatic spraying production line of invention, comprises: hanging conveying line 2, feeding mechanism 3, spraying room 4, drying channel 5 and heating system 6, blanking mechanism 8, it is characterized in that: described automatic spraying production line consists of The hanging conveying line 2 sequentially connects the feeding mechanism 3, the spraying room 4, the drying channel 5, and the unloading mechanism 8 into a closed-loop spraying production line connected end to end; the spraying production line is provided with one or multiple Spraying chamber 4, spraying chamber 4 is the double-chamber structure that spraying outer chamber 10 and spraying inner chamber 11 form, and the outside of spraying outer chamber 10 is provided with blower 12 that communicates with spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com