Turnable-heating-tube mounting structure and electric oven

A technology of installation structure and heating tube, applied in the direction of roaster/barbecue grid, kitchen utensils, household utensils, etc., can solve problems such as odor, bacteria breeding, parts damage, etc., to improve service life, avoid influence, and facilitate cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

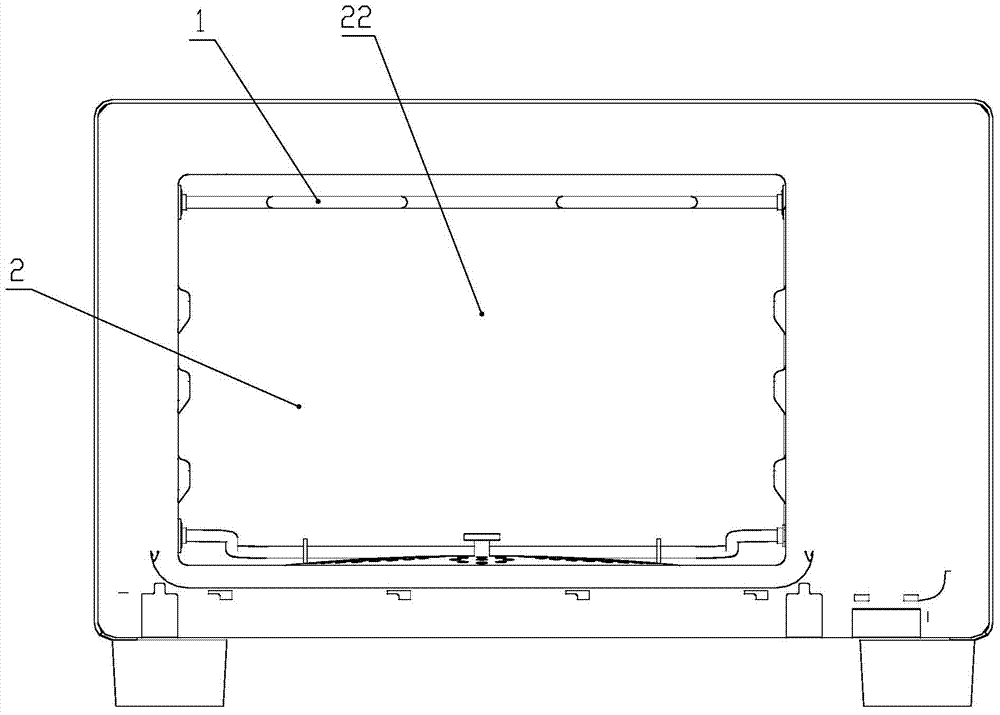

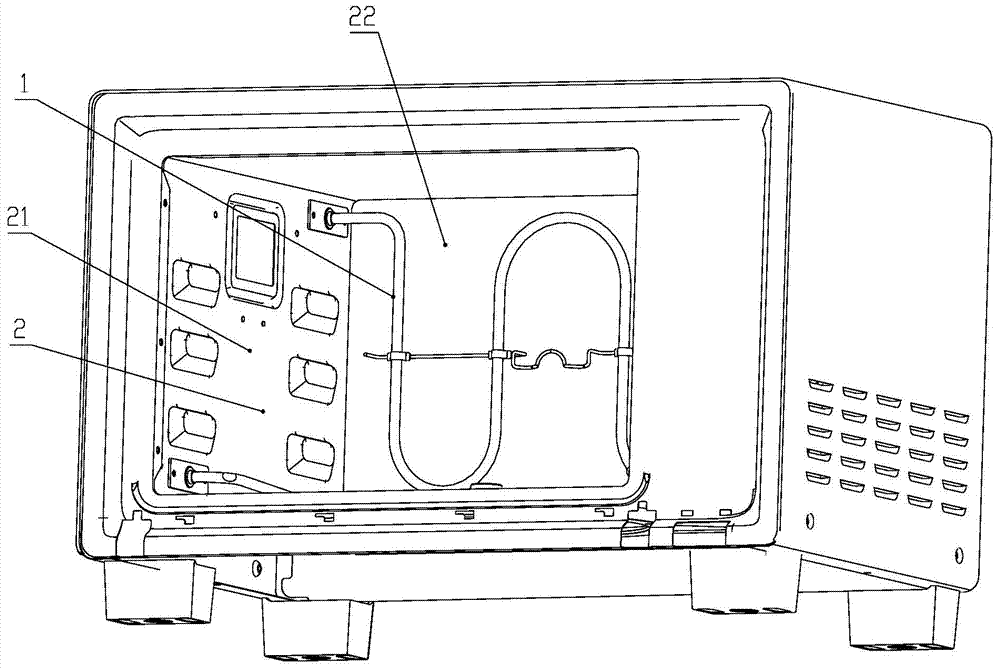

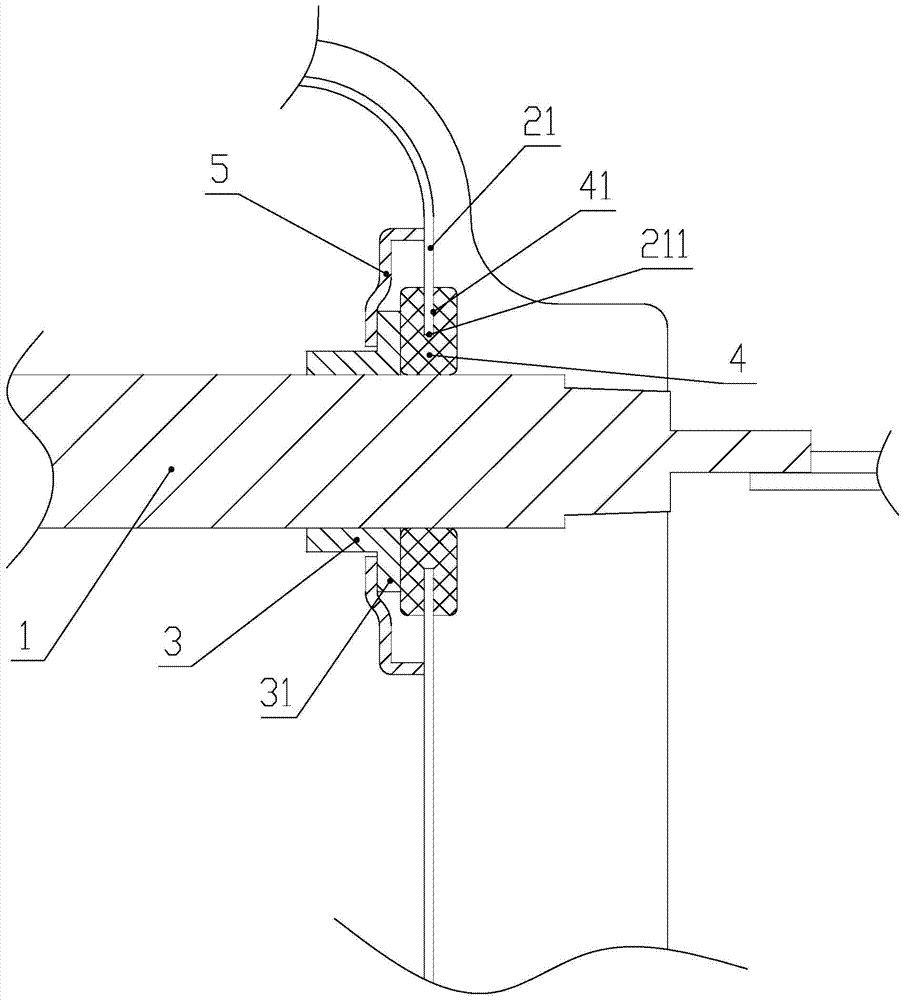

[0034] image 3 It is a schematic diagram of the installation structure of the reversible heating tube in this embodiment. As shown in the figure, both ends of the heating tube 1 are sleeved with rotating shaft sleeves 3, the heating tube 1 is fixedly connected with the rotating shaft sleeve 3, and the two ends of the heating tube 1 are respectively connected to the axis of the rotating shaft sleeve 3 sleeved on it. coincide.

[0035] Both side walls 21 of the inner container are provided with heating tube installation holes 211. The two ends of the heating tube 1 are inserted into the heating tube installation holes 211. Between the heating tube installation holes 211 and the two ends of the heating tube 1, there are Seal ring 4. The arrangement of the sealing ring 4 can provide a certain damping for the rotation of the heating tube 1 on the one hand, and can play a sealing role on the other hand, avoiding the influence of water vapor overflow on the electrical performance of t...

Embodiment 2

[0039] Figure 4 It is a schematic diagram of the installation structure of the reversible heating tube in this embodiment. As shown in the figure, the installation structure is basically the same as that of the first embodiment. Both ends of the heating tube 1 are sleeved with rotating shaft sleeves 3, the heating tube 1 is fixedly connected to the rotating shaft sleeve 3, and both ends of the heating tube 1 are connected to the sleeves respectively. The axis of the rotating shaft sleeve 3 on it coincides. Both side walls 21 of the inner container are provided with heating tube installation holes 211. The two ends of the heating tube 1 are inserted into the heating tube installation holes 211. Between the heating tube installation holes 211 and the two ends of the heating tube 1, there are Seal ring 4. A mounting groove 41 is formed on the outer peripheral surface of the sealing ring 4, and the sealing ring 4 is clamped and fixed to the side wall 21 of the inner container th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com