Centralized type automatic feed dispensing and oxygen aeration method for aquaculture

A kind of aquaculture and centralized technology, applied in application, fish farming, animal husbandry, etc., can solve the problems of ineffective oxygenation in middle and lower water bodies, high purchase and use costs, limited feeding area and angle, etc. , to achieve the effect of improving the level of facilities and equipment and labor productivity, reducing equipment investment and use costs, and improving the effect of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0036] In this embodiment, aiming at the problems existing in the existing feeding machines and the needs of large-scale aquaculture, a centralized automatic feeding oxygenation method for aquaculture is designed.

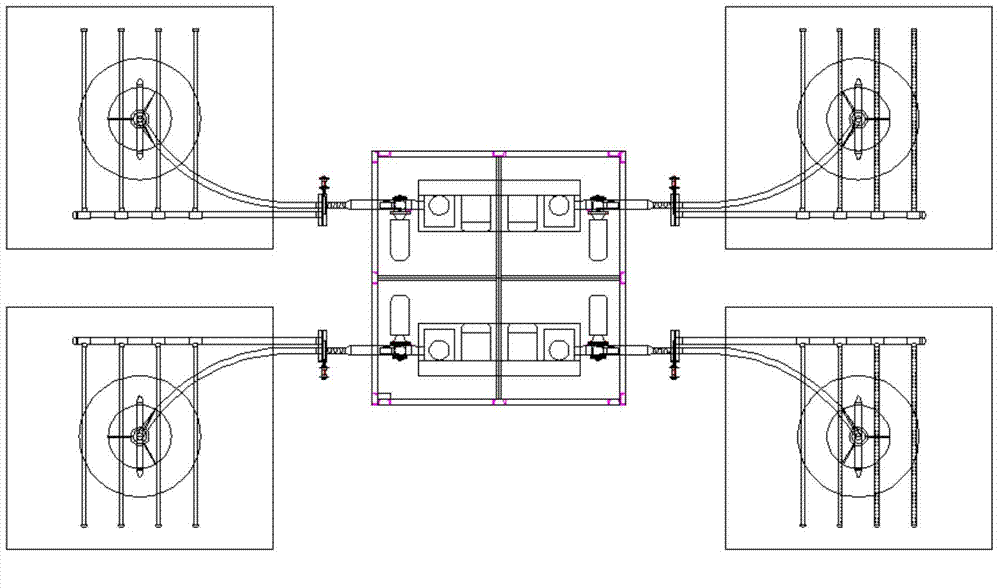

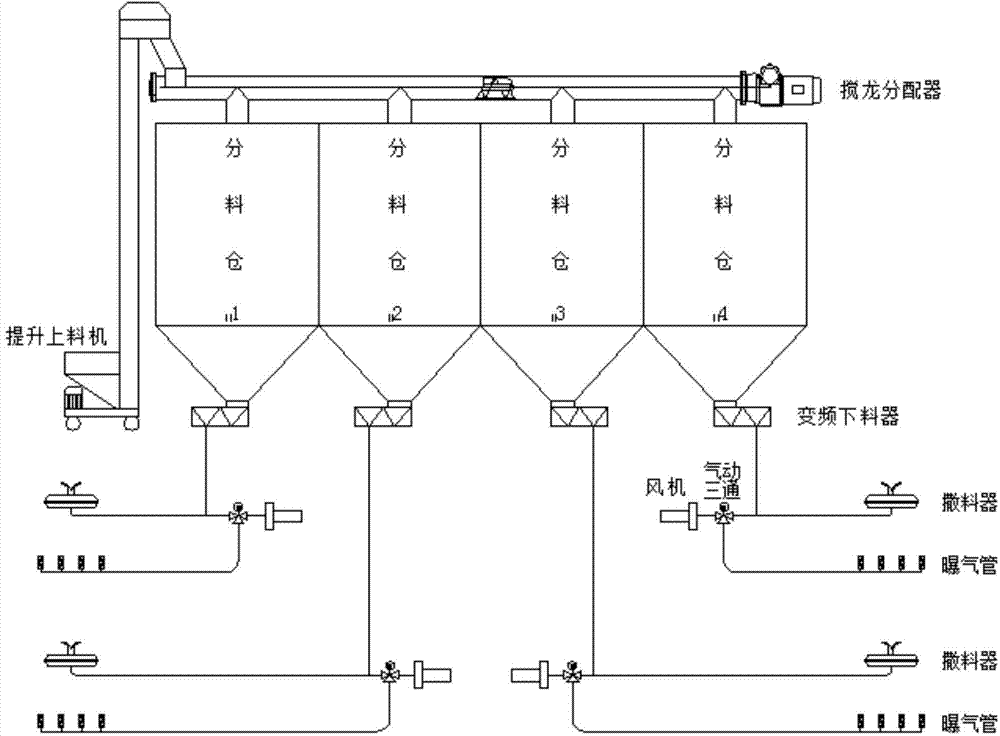

[0037] see Figure 1-Figure 2 , a centralized automatic feeding method for increasing oxygen in aquaculture, comprising the following steps: A) in the group of standardized breeding ponds, a large-scale feed feeding station is set for every 4 or more ponds; B) supplying feed manufacturers The vehicle directly sends the feed to the feed feeding station, lifts it to the top of the combined feed bin group through the lifting feeder, and distributes it to each distribution bin through the auger distributor; C) each distribution bin passes through the frequency conversion feeder at the bottom D) The high-pressure blower at the bottom di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com