Pre-heating device for a fuel injection system

A technology of fuel injection system and preheating device, which is applied in the direction of fuel injection device, fuel heat treatment device, special fuel injection device, etc. It can solve the problems of a large amount of electric energy and time, and achieve the effect of high corrosion risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

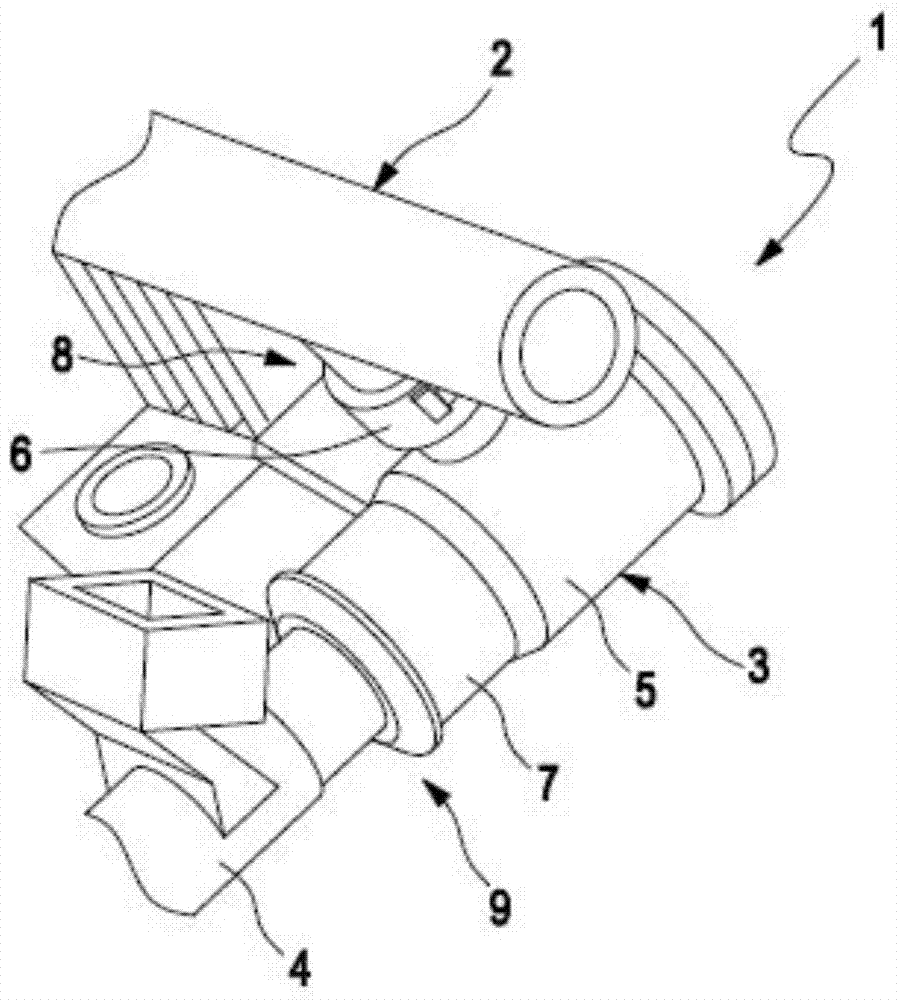

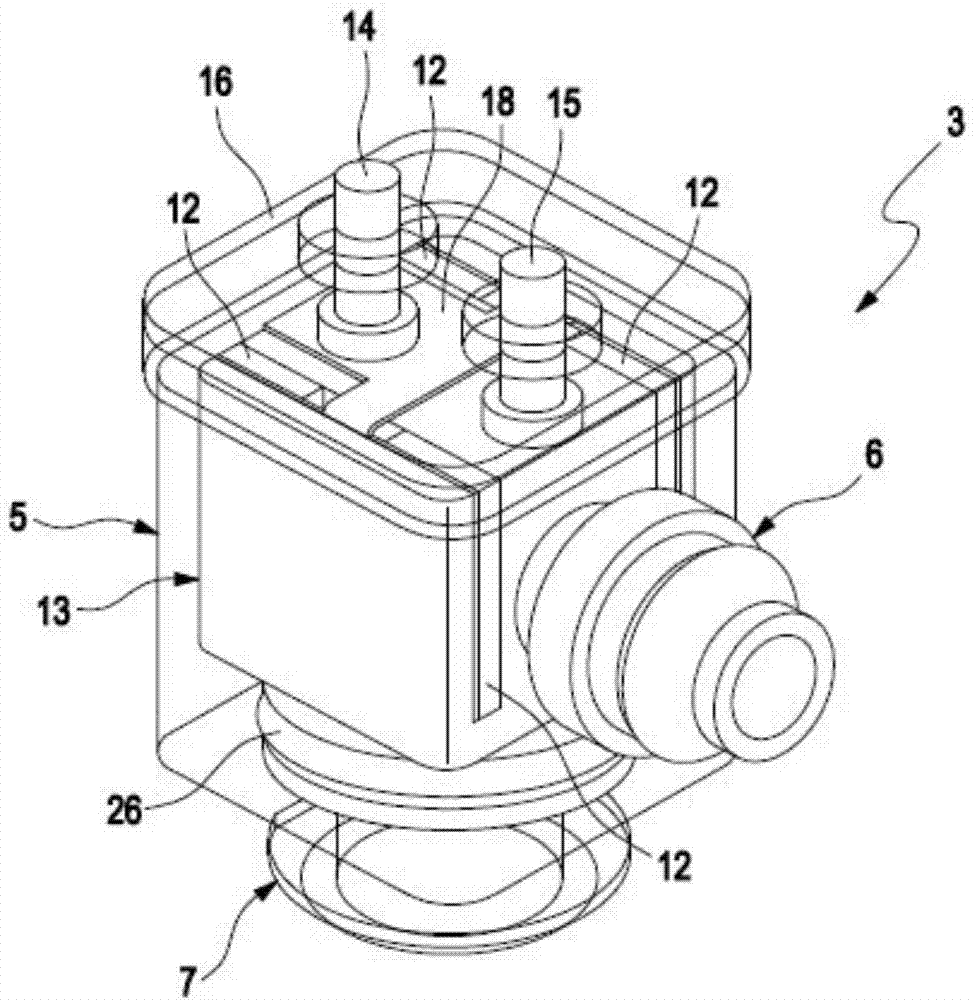

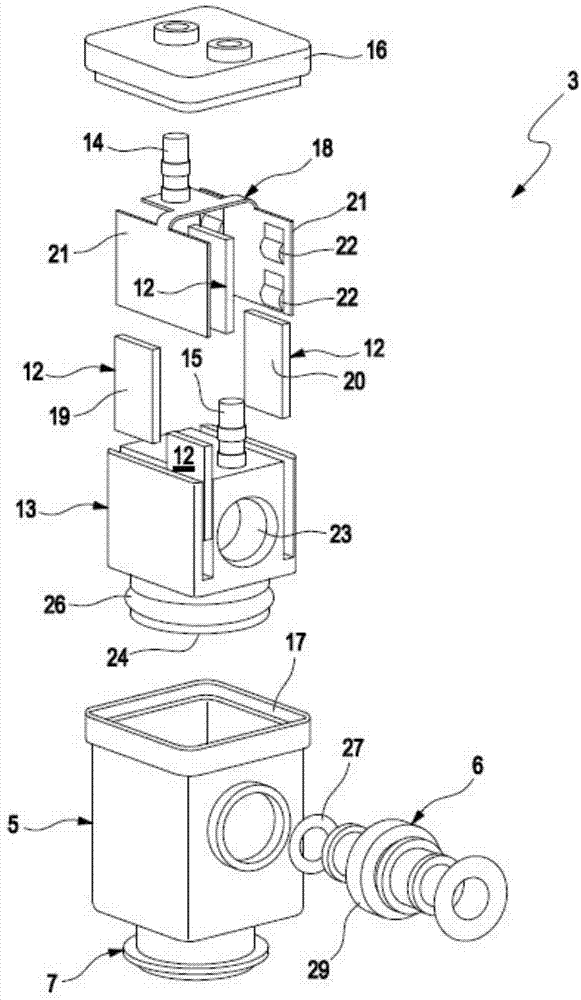

[0052] according to figure 1 , the fuel injection system 1 includes at least one distributor rail 2, several preheating devices 3 and several fuel injectors 4, and the fuel injection system 1 is used in an internal combustion engine (not shown) to supply fuel to the combustion chamber of the internal combustion engine . The distributor rail 2 is used for supplying liquid fuel, and may also be called "rail" or "common rail". Each preheating device 3 is used to preheat fuel before the fuel reaches each fuel injector 4 . For this purpose, a preheating device 3 is fluidly arranged between the distributor rail 2 and the individual fuel injectors 4 . The preheating device 3 thus comprises a housing 5 which has an inlet connection 6 via which the preheating device 3 can be directly connected to the distributor rail 2 . Furthermore, the housing 5 has an outlet connection 7 via which the individual fuel injectors 4 can be directly connected to the individual preheating devices 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com