Brushless claw-pole power generator

A generator and claw pole technology, applied to synchronous generators, etc., can solve problems such as short circuit of electronic devices, fire, accelerated aging of surrounding components, etc., and achieve the effects of prolonging service life, simple structure, and preventing short circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

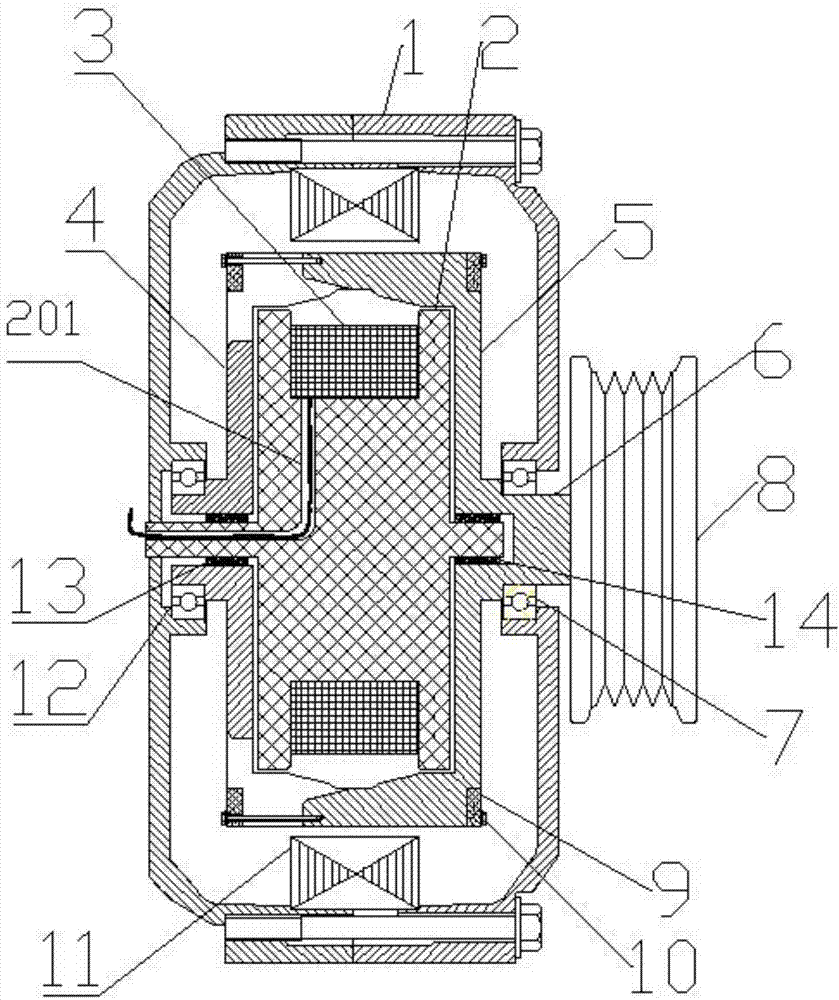

[0016] As shown in the figure, a brushless claw-pole generator includes a housing 1, an excitation core 2 is fixedly installed on the left end of the inner wall of the housing 1, and an excitation winding 3 wound in a circumferential direction is arranged on the excitation core 2 , the field core 2 is provided with a wire hole 201 through which the lead wire of the field winding 3 passes through the outside, and two oppositely arranged left claw poles 4 are arranged outside the field core 3 in the casing 1 and the right claw pole 5, left and right transmission shafts 15, 6 are fixed at the center of the outer end face of the right claw pole 5, and the right transmission shaft 6 passes through the right end of the housing 1 and is connected with the housing A bearing I7 is installed between 1, and a transmission wheel 8 is fixedly installed at the passing end of the right transmission shaft 6; an annular non-magnetic ring 9 is respectively placed on the outer end faces of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com