Organic light-emitting element

A technology for organic light-emitting elements and light-emitting elements, applied in organic semiconductor devices, electrical components, optics, etc., can solve the problem of not simultaneously solving the problems of luminous efficiency and chromaticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0227] After the alkali-free glass is ultrasonically cleaned in isopropanol for 15 minutes, it is subjected to UV ozone cleaning treatment in the atmosphere for 30 minutes. Using the vacuum evaporation method, first evaporate aluminum 100nm to make the anode, then on the anode hole injection layer (NPD and F4-TCNQ (weight ratio 97:3), 50nm), hole transport layer (NPD, 80nm), blue Emitting layer (BH and BD (weight ratio 97:3, 20nm), electron transport layer (Alq 3 , 30nm), the electron injection layer (LiF, 1nm) was sequentially stacked and evaporated, and Mg and Ag (weight ratio 10:1, 15nm) were co-evaporated to make a semi-transparent cathode.

[0228] The compounds used above are shown below.

[0229]

[0230]

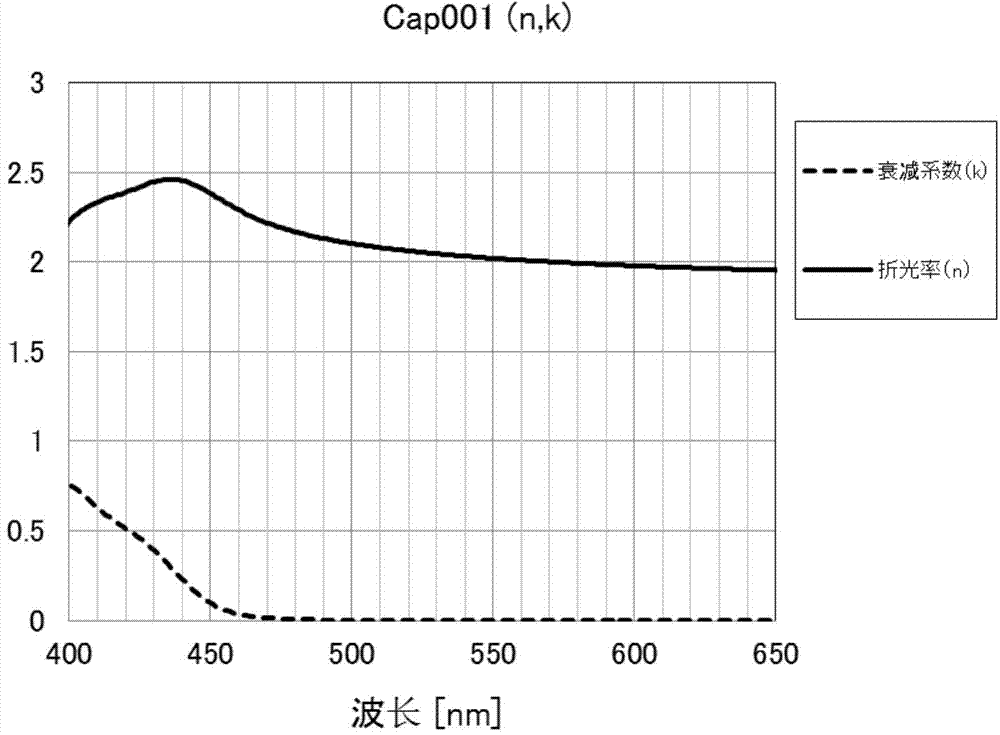

[0231] Cap001 (60nm) was then evaporated as a capping layer.

[0232] Finally, in a glove box in a dry nitrogen atmosphere, seal the light-emitting element with a sealing plate made of non-alkali glass with an epoxy resin adhesive.

[0233] The luminance and...

Embodiment 2

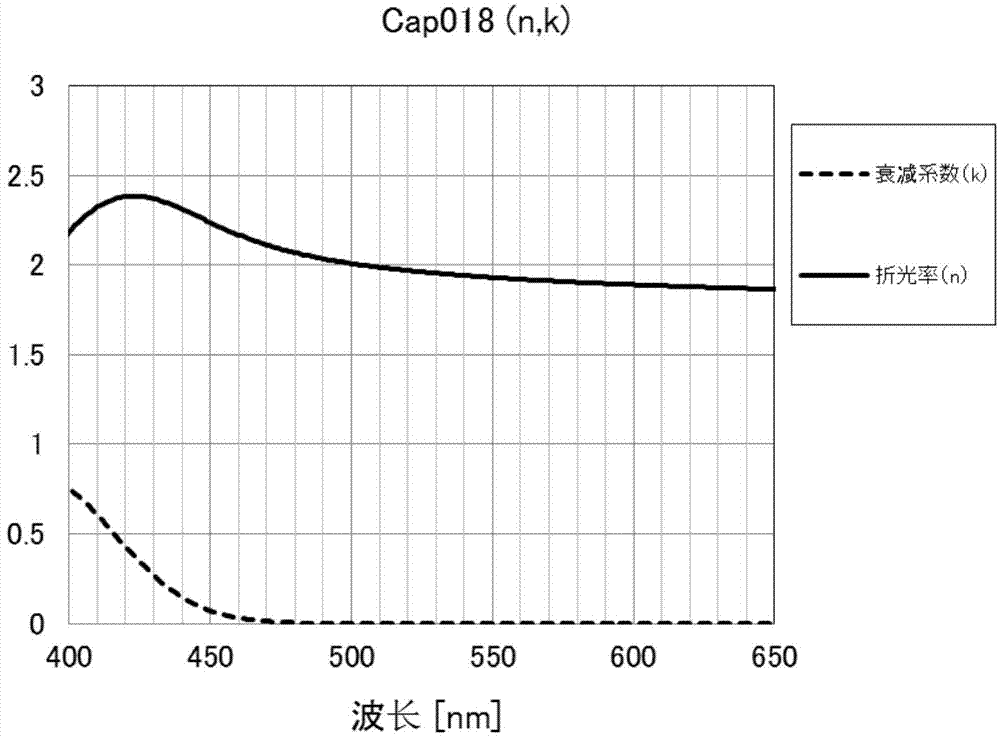

[0236] Except that the material of the covering layer is Cap018, the rest are the same as that of Example 1.

[0237] An organic light-emitting element was evaluated. See Table 2 for the evaluation results.

Embodiment 3

[0239] Except that the material of the cover layer is Cap039, the rest are the same as that of Example 1.

[0240] An organic light-emitting element was evaluated. See Table 2 for the evaluation results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com