Method for establishing liquid curved membrane flow system of fusion reactor divertor flow stability

A technology of divertor and stability, which is applied in the field of liquid curved membrane flow system to establish the flow stability of fusion reactor divertor, which can solve the problem of magnetic fluid instability, accumulation thickening or even flow blockage, inability to completely cover the bottom wall or even development For problems such as stream flow, to achieve the effect of preventing splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The method for establishing the liquid curved membrane flow system of the fusion reactor divertor flow stability according to the present invention comprises the following steps:

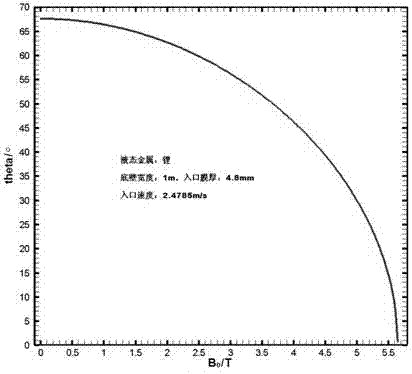

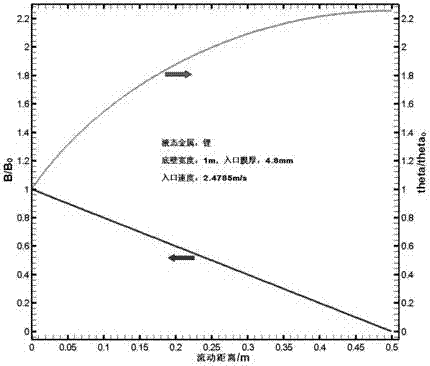

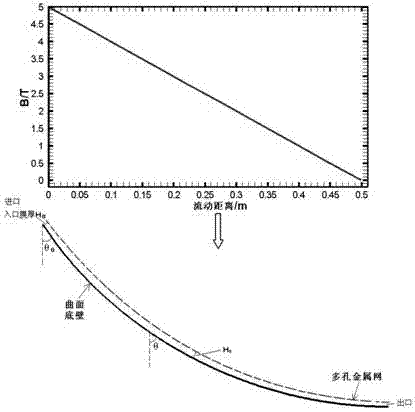

[0025] Step 1: Find the relationship between the local magnetic field strength and the inclination angle under the stable flow state of the liquid metal film flow, and control the magnetic fluid instability caused by the strong gradient magnetic field by changing the local inclination angle at different flow distances of the film flow to adapt to the change of the gradient magnetic field , that is, the shape of the curved bottom wall is used to adapt to the change of the strong gradient magnetic field;

[0026] Step 2: Use the method of fixing the metal mesh above the curved bottom wall to ensure that the liquid metal flows along the curved bottom wall with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com