Method for monitoring abnormal conditions of working region of warehouse logistics robot

A work area, abnormal situation technology, applied in the direction of instruments, image data processing, closed-circuit television systems, etc., can solve the problem of inability to effectively monitor abnormal conditions, and achieve the effect of ensuring normal and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056]The technical solution of the present invention will be further described in detail in conjunction with the accompanying drawings and embodiments.

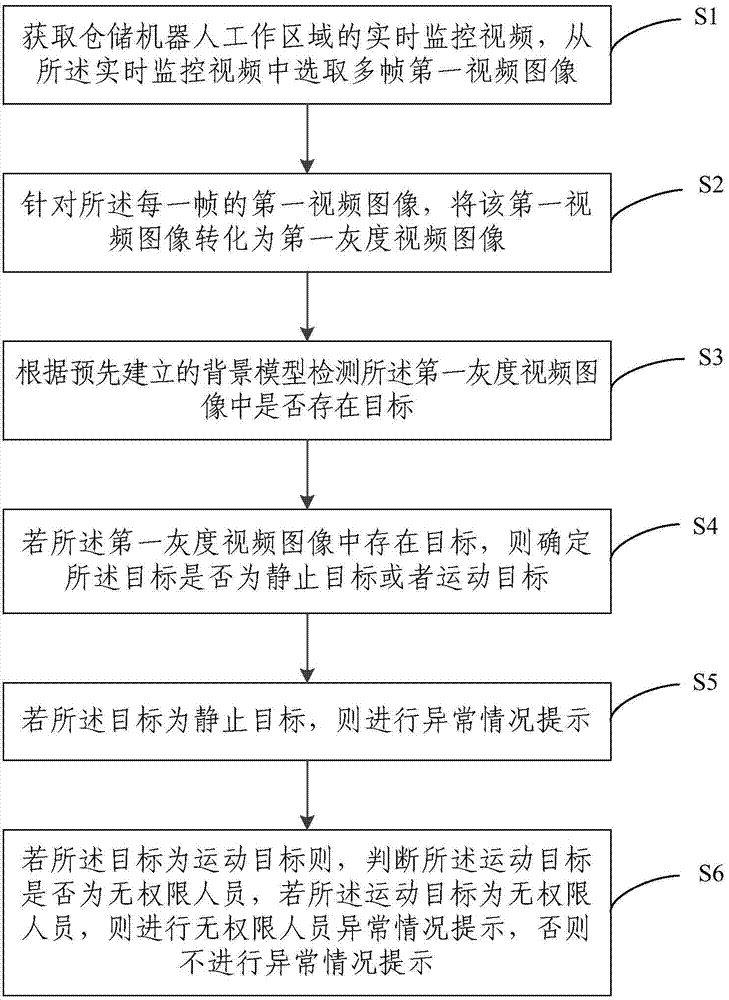

[0057] figure 1 It shows a schematic flow chart of the method for monitoring the abnormal situation in the working area of the warehousing logistics robot in this embodiment, as shown in figure 1 As shown, a method for monitoring abnormalities in the working area of a warehousing logistics robot provided in this embodiment includes:

[0058] S1. Obtain a real-time monitoring video of the working area of the storage robot, and select multiple frames of first video images from the real-time monitoring video. The working area of the storage robot refers to the movement track area of the storage robot.

[0059] S2. For the first video image of each frame, convert the first video image into a first grayscale video image;

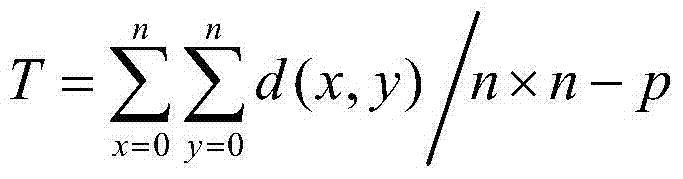

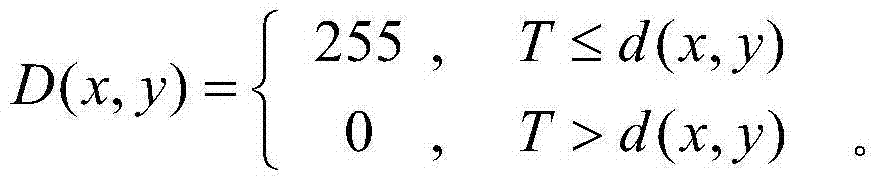

[0060] S3, detecting whether there is a target in the first grayscale video image according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com