Device and method for measuring film thickness

A film thickness and measuring device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of high price of microscopic instruments, change of coating rate, non-linear law, etc., and achieve easy popularization and application and simple operation. , the effect of low environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

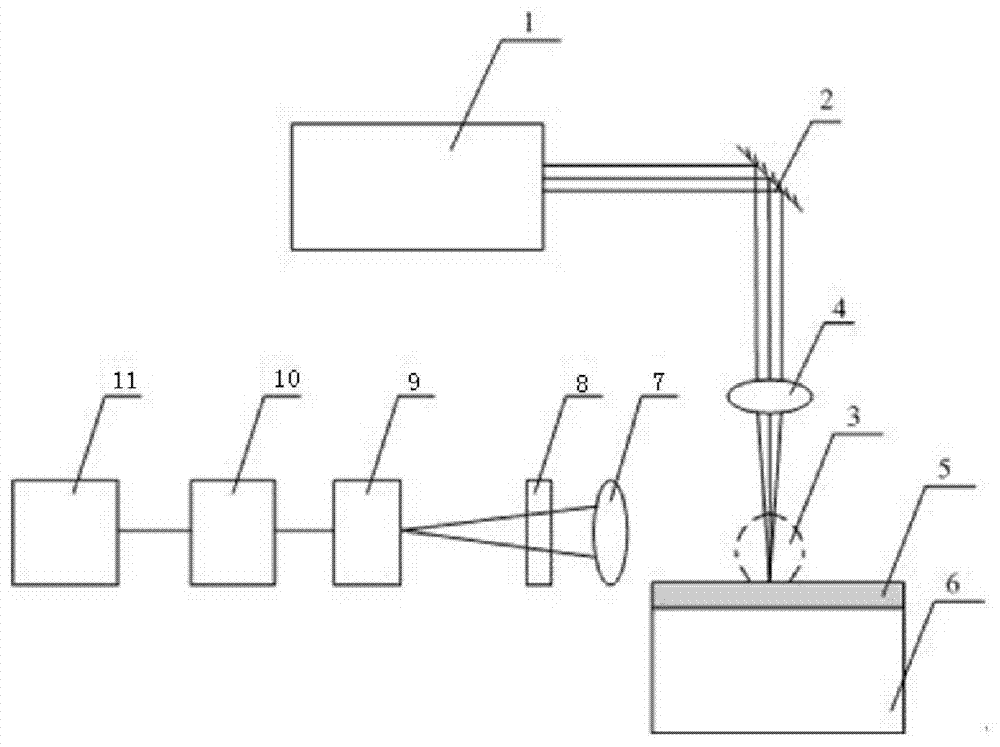

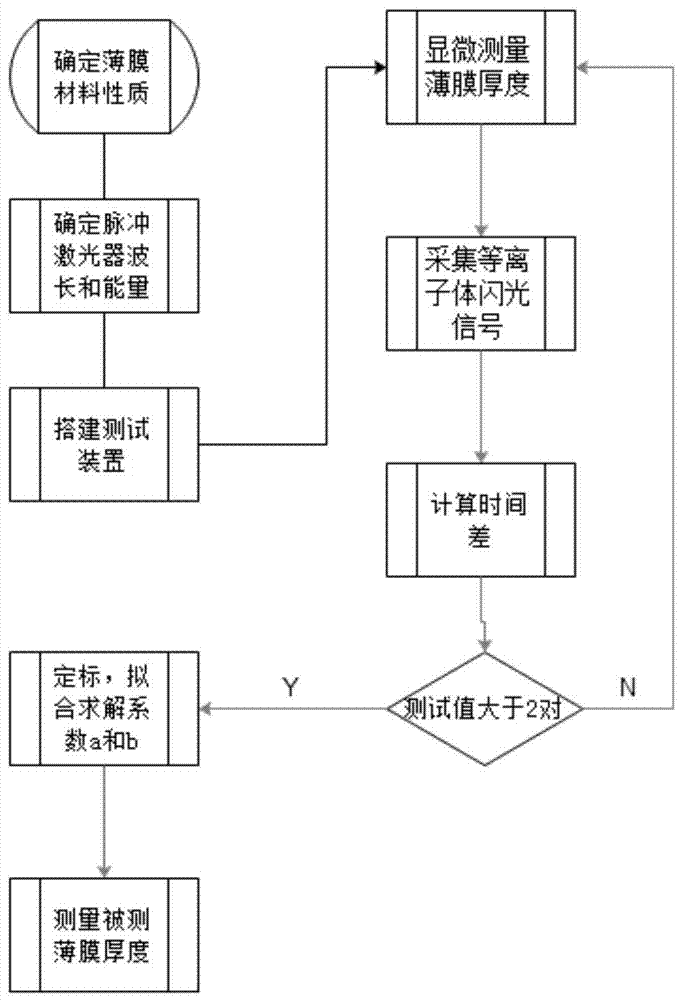

[0038] (1) Select laser 1 as SGR-10 series high-power pulsed Nd: YAG laser (SpitLight1000), output 1064nm infrared pulse Gaussian laser beam, laser pulse width 10ns, repetition frequency 10Hz, divergence angle ≤0.7mrad, single pulse laser The output energy is adjustable (the stable energy range is 50mJ~800mJ).

[0039] The photodetector 9 is selected as the photodiode of thorlab company, the model is DET10A / M, the rise time is less than 1ns, the response wavelength range is 200~1100nm, and the four-channel Yokogawa DL9140 oscilloscope is selected, the bandwidth is 1GHz, and the highest sampling rate is 2.5GS / s.

[0040] The focal length of the first focusing lens 4 is 160 mm, and the converging spot diameter is 50 um; the focal length of the second focusing lens 7 is 22.5 cm, and the plasma flash signal is converged on the receiving surface of the photodetector;

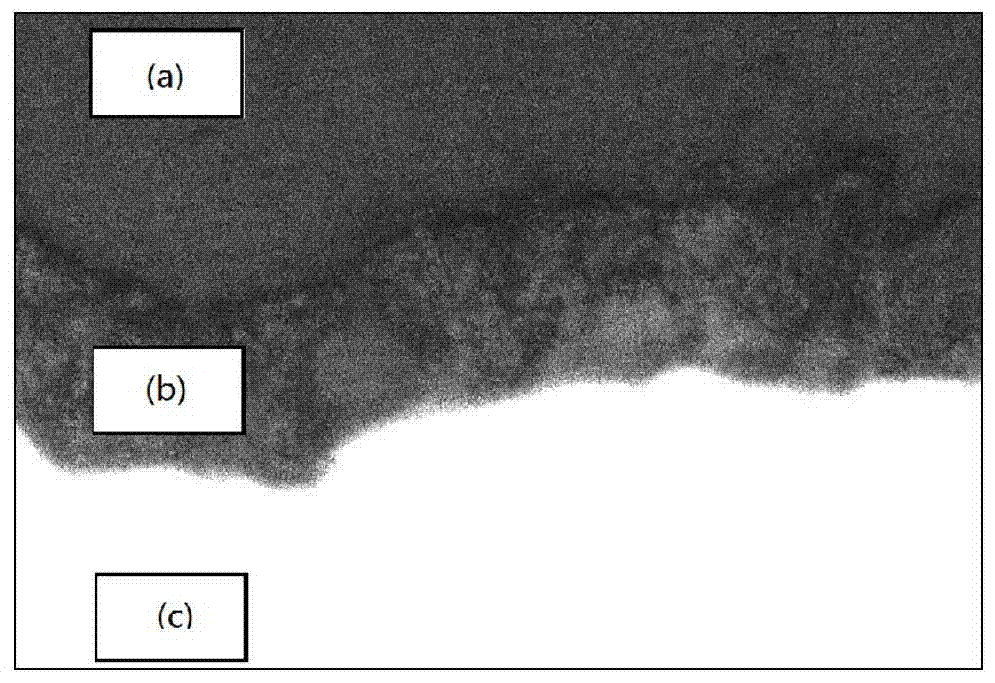

[0041] The metal substrate is selected as marine steel Q235B, and the surface film is ferric oxide, such as image 3 As...

Embodiment 2

[0046] (1) Select laser 1 as a Q-switched high-power neodymium glass solid laser, with a laser wavelength of 1064nm, a laser pulse width of 20ns, an output energy of 500mJ-20J, and a repetition frequency of 1Hz.

[0047] The photodetector 9 is selected as the photodiode of thorlab company, the model is DET10A / M, the rise time is less than 1ns, the response wavelength range is 200~1100nm, and the four-channel Yokogawa DL9140 oscilloscope is selected, the bandwidth is 1GHz, and the highest sampling rate is 2.5GS / s.

[0048] The focal length of the first focusing lens 4 is 1.5m, and the converging spot diameter is 5mm; the focal length of the second focusing lens 7 is 30cm, and the plasma flash signal is converged on the receiving surface of the photodetector;

[0049] The metal substrate is selected as a medical titanium alloy, the surface film is hydroxyapatite, and the film thicknesses of multiple samples are also different.

[0050] (2) Select the pulse laser energy as 10J, using su...

Embodiment 3

[0054] (1) The laser 1 is selected as a French high-power laser, the laser wavelength is 1064nm, the laser pulse width is 8ns, the output energy is 50mJ-12J, and the repetition frequency is 5Hz.

[0055] The photodetector 9 is selected as the photodiode of thorlab company, the model is DET10A / M, the rise time is less than 1ns, the response wavelength range is 200~1100nm, and the four-channel Yokogawa DL9140 oscilloscope is selected, the bandwidth is 1GHz, and the highest sampling rate is 2.5GS / s.

[0056] The focal length of the first focusing lens 4 is 1 m, and the converging spot diameter is 2 mm; the focal length of the second focusing lens 7 is 22.5 cm, and the plasma flash signal is concentrated on the receiving surface of the photodetector.

[0057] The metal substrate is pure aluminum, the surface film is black paint, and the film thicknesses of multiple samples are also different.

[0058] (2) Select the pulse laser energy to be 8J, use such as figure 1 The device shown and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com