Coupling staged combustion and smoke recirculation low NOx chain grate furnace

A flue gas recirculation and staged combustion technology, applied in the field of low NOx chain furnaces and chain furnaces, can solve the problems of inability to achieve high efficiency and low emission, high emissions of chain furnaces, achieve good ignition, stable combustion, burnout, reduce combustion temperature and combustion. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

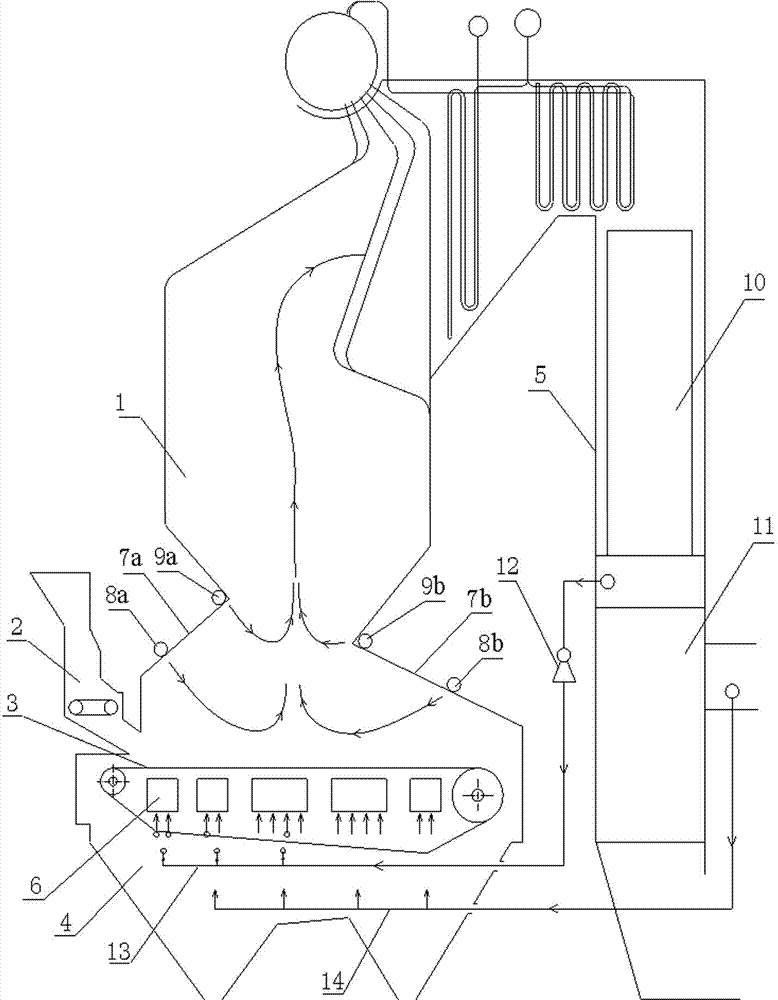

[0023] to combine figure 1 Describe this embodiment, the coupling staged combustion and flue gas recirculation of the present invention with low NO x Chain furnace, the chain furnace is composed of furnace 1, coal feeder 2, chain grate 3, slag hopper 4 and tail flue 5; the furnace 1 is divided into upper and lower parts by front furnace arch 7a and rear furnace arch 7b; An economizer 10 and an air preheater 11 are arranged from top to bottom in the tail flue 5; a plurality of primary air chambers 6 are arranged in the space area wrapped by the chain grate 3, and a plurality of primary air chambers 6 are arranged along the The direction of travel of the chain grate 3 (from left to right) is arranged in a "one" shape, and the outlets of the multiple primary air chambers 6 communicate with the chain grate 3 to supply the chain grate. 3 The primary air 14 required for the combustion of the upper coal seam; a plurality of front wall secondary air nozzles 8a and a plurality of rea...

Embodiment approach 2

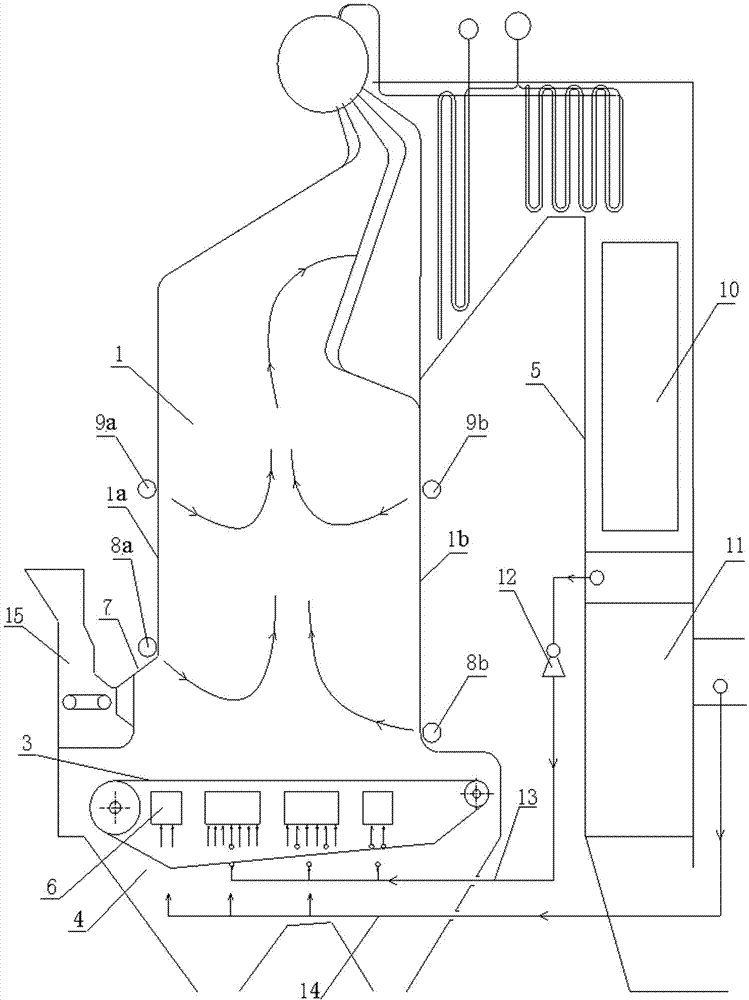

[0029] to combine figure 2 To illustrate this embodiment, the present invention couples air classification and flue gas recirculation to low NO x The chain furnace can also be equipped with an inverted coal thrower grate. The chain furnace is composed of a furnace 1, a coal feeder 15, a chain grate 3, a slag hopper 4 and a tail flue 5. The coal particles are formed by the coal feeder. The coal machine 15 is thrown to the right end of the chain grate 3, and the chain grate 3 is reversed from right to left; the furnace 1 is provided with a front wall 1a and a rear wall 1b, and the root of the front wall 1a has A small front furnace arch 7; an economizer 10 and an air preheater 11 are arranged from top to bottom in the tail flue 5; a plurality of primary air chambers 6 are arranged in the space area wrapped by the chain grate 3, A plurality of primary air chambers 6 are arranged in a "one" shape along the direction of travel of the chain grate 3 (from right to left) and communi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com