Portable engine-driven centrifugal pump

An engine-driven, centrifugal water pump technology, applied in engine components, engine cooling, machine/engine, etc., can solve problems such as damage to the sealing effect of piston rings, compression ratio, no interface for driving equipment cooling, and more carbon deposits in the engine. The effect of reducing the operation steps and technical difficulty, being easy to carry and transporting, and reducing the weight of the pump body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the embodiments and accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

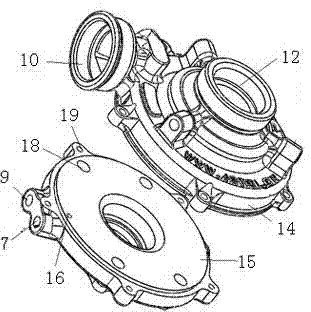

[0018] The portable engine-driven centrifugal water pump of the present invention, as figure 1 , figure 2 , image 3 and Figure 5 Shown, comprise cylinder, water pump and muffler 29. Water pump is provided with pump inlet 10, pump outlet 12, pump cover 14 and pump housing 15, and cylinder comprises cylinder head 3 and cylinder housing 41, and cylinder housing and pump housing cooperate to install, and muffler 29 is connected with the exhaust port of cylinder. A cylinder cooling water channel is arranged inside the cylinder head, and a cooling water inlet 5 and a return water outlet 4 are arranged outside the cylinder hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com