Liquefied natural gas gasification system and method based on circulating solar power generation

A technology of liquefied natural gas and liquefied natural gas tanks, applied in the directions of solar thermal power generation, mechanical power generated by solar energy, machines/engines, etc., can solve the problems of complex systems, large energy consumption, inconvenient operation, etc., and achieve saving of fossil energy and system Simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

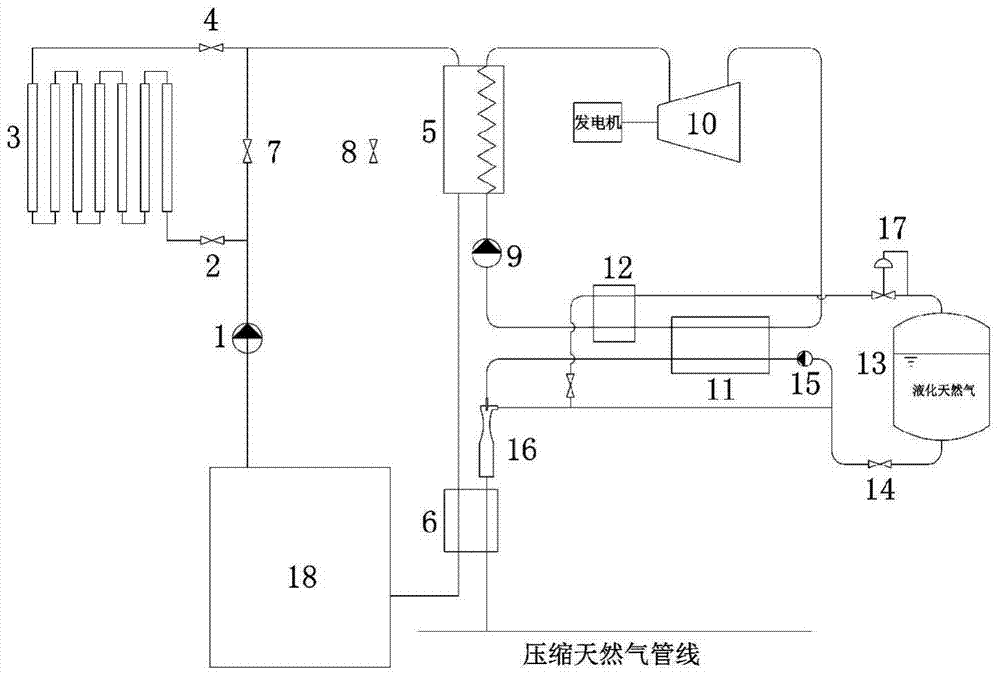

[0027] Such as figure 1 A liquefied natural gas gasification system based on solar cycle power generation is shown, including a solar heat collection and heat storage unit, an organic Rankine cycle power generation unit and a liquefied natural gas gasification unit, and the solar heat collection and heat storage unit includes a heat storage tank 18, a high temperature Pump 1, first valve 2, solar heat collector 3, second valve 4, first heat exchanger 5, second heat exchanger 6, third valve 7, fourth valve 8 and pipeline; organic Rankine cycle power generation The unit includes a working medium pump 9, a first heat exchanger 5, an expander 10, a third heat exchanger 11, a fourth heat exchanger 12 and corresponding pipelines; the (jet type) LNG gasification unit includes a LNG tank 13, The fifth valve 14, the liquefie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com