Proportional control system applied to height adjustment of coal mining machine

A proportional control and proportional controller technology, which is used in earth-moving drilling, slitting machinery, driving devices, etc., can solve the problems of inability to enter a stable height, unsatisfactory control effect, and inability to realize the intelligent function of memory cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

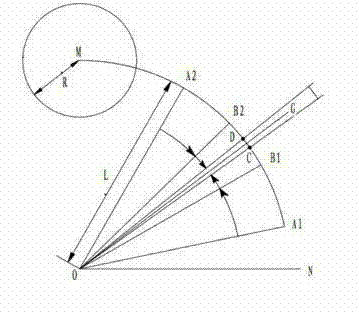

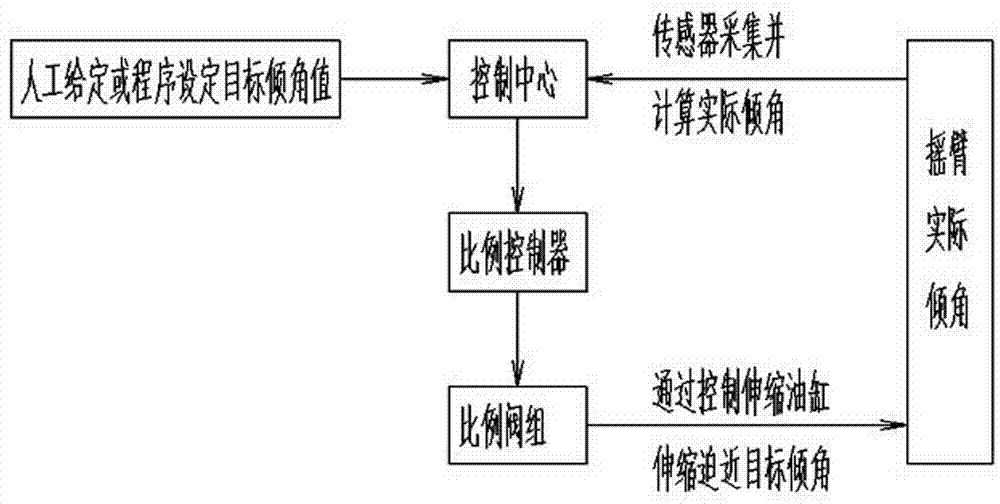

[0026] like figure 1 The proportional control system applied to the height adjustment of the shearer includes a control center, a proportional controller, a proportional valve group, a rotary encoder and a stroke sensor. The rotary encoder is installed on the rocker arm of the shearer, and the stroke The sensor is connected to the telescopic oil cylinder of the rocker arm of the coal mining machine, the rotary encoder and the stroke sensor are connected to the control center, the proportional valve group is connected to the telescopic cylinder of the rocker arm of the coal mining machine, the control center drives the proportional controller, and the proportional controller controls the proportional valve Group.

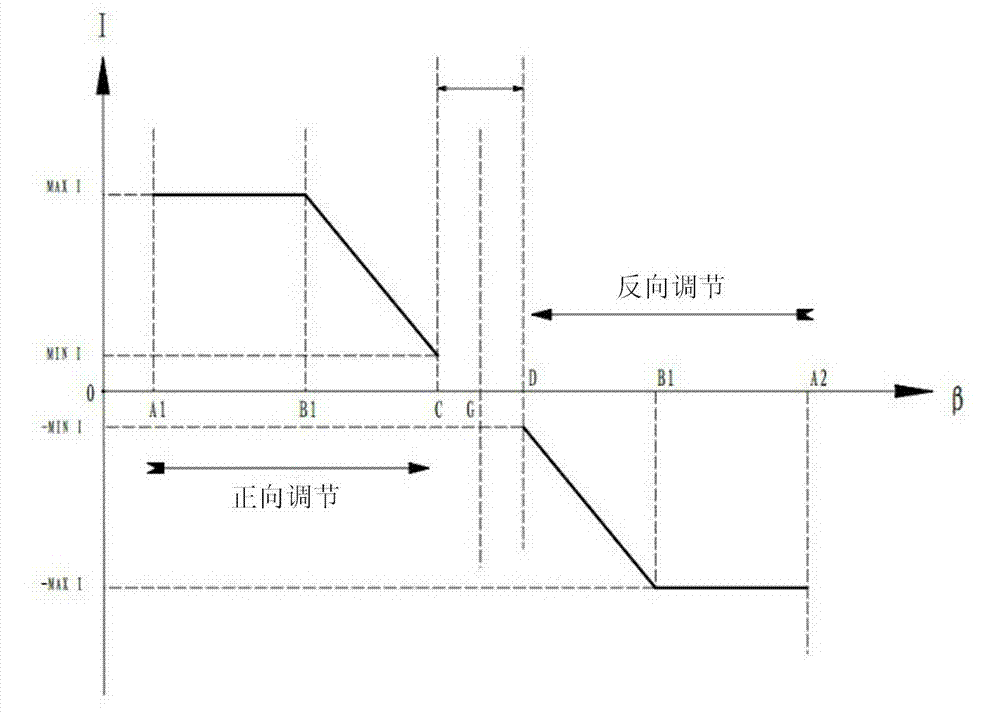

[0027] The specific control process of the system is:

[0028] The command output from the control center (that is, the DSP control system) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com