Zr-based amorphous alloy and manufacturing method thereof

A zirconium-based amorphous alloy and benchmark technology, applied in the field of zirconium-based amorphous alloy and its preparation, can solve the problems of high purity requirements of raw materials, achieve the effect of reducing material costs, reducing requirements, and improving the ability of amorphous formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

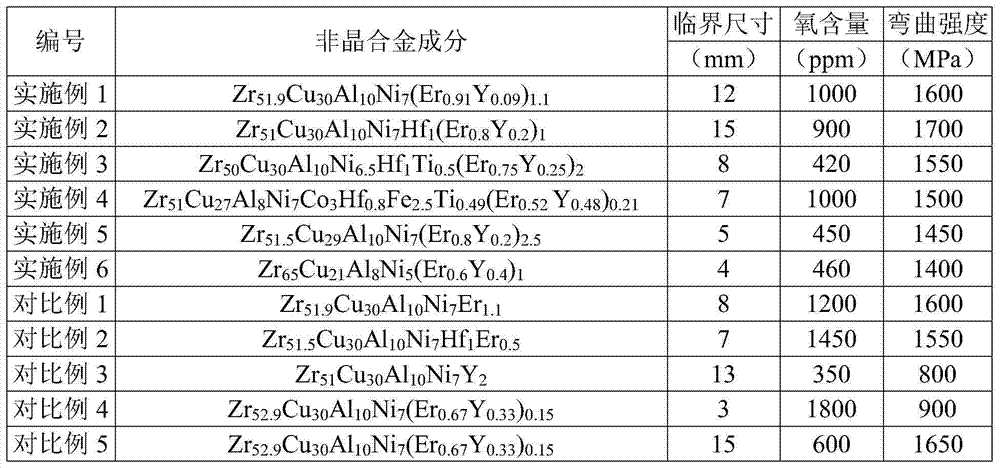

Examples

Embodiment 1

[0035] This embodiment illustrates that the zirconium-based amorphous alloy Zr provided by the present invention 51.9 Cu 30 Al 10 Ni 7 (Er 0.91 Y 0.09 ) 1.1 method of preparation.

[0036] Put the raw materials of each component into the vacuum smelting furnace, and evacuate to 50Pa, then pass in argon gas with a purity of 99.99% by volume as a protective gas, and carry out alloy smelting. The melting temperature is 1100 ° C, and the melting time is 15 minutes. The alloy raw material is fully melted. Then remelt 3 times to make it fully alloyed. The smelting temperature in the smelting process is obtained by infrared temperature measurement.

[0037] Metal zirconium adopts elemental metal with a metal purity greater than 99% by weight, and Al, Cu, Ni, Er, Y adopts elemental metal with a purity greater than 99% by weight.

[0038] The molten alloy sample is cast into a metal mold by high pressure casting (the pressure is 20MPa, the mold material is SKD61), and cooled a...

Embodiment 2

[0044] This embodiment illustrates that the zirconium-based amorphous alloy Zr provided by the present invention 51 Cu 30 Al 10 Ni 7 f 1 (Er 0.8 Y 0.2 ) 1 method of preparation.

[0045] Put the raw materials of each component into the vacuum smelting furnace, and evacuate to 50Pa, then pass in argon gas with a purity of 99.99% by volume as a protective gas, and carry out alloy smelting. The melting temperature is 1100 ° C, and the melting time is 15 minutes. The alloy raw material is fully melted. Then remelt 3 times to make it fully alloyed. The smelting temperature in the smelting process is obtained by infrared temperature measurement.

[0046] Metal zirconium adopts industrial-grade HZr-1 zirconium material with a metal (Zr+Hf) purity greater than 99% by weight, Al, Cu, Ni, Hf, Er, and Y use elemental metals with a purity greater than 99% by weight, and Er and Y use AlErY intermediate alloy.

[0047] The molten alloy sample is cast into a metal mold by high pre...

Embodiment 3

[0053] This embodiment illustrates that the zirconium-based amorphous alloy Zr provided by the present invention 50 Cu 30 Al 10 Ni 6.5 f 1 Ti 0.5 (Er 0.75 Y 0.25 ) 2 method of preparation.

[0054] Put the raw materials of each component into the vacuum smelting furnace, and evacuate to 50Pa, then pass in argon gas with a purity of 99.99% by volume as a protective gas, and carry out alloy smelting. The melting temperature is 1100 ° C, and the melting time is 15 minutes. The alloy raw material is fully melted. Then remelt 3 times to make it fully alloyed. The smelting temperature in the smelting process is obtained by infrared temperature measurement.

[0055] Metal zirconium adopts industrial-grade HZr-1 zirconium material with a metal (Zr+Hf) purity greater than 99% by weight, Al, Cu, Ni, Hf, Er, and Y use elemental metals with a purity greater than 99% by weight, and Er and Y use AlErY intermediate Alloy, Ti adopts AlTi master alloy.

[0056] The molten alloy sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com